Tonight was a big night for my class when they learned how to make bowls on purpose instead of a cylinder gone bad… whoops, here’s a bowl! So we started the night with a demonstration of how to make a proper bowl. Then, as my students went back to try their hand at the wheel, I continued to throw more bowls. Once I had finished the bag of clay, I had twelve basic bowls – all kind of the same size & shape. All of them basically round. All of them basically plain.

Part Two of the class demo is to convince my students to “play with their clay” and get it to do something fun. I try to instill in them that the wheel is only a tool and it’s up to them to be creative and turn it into a “work of art.” To make it their own! So my goal was to show them a few quick tricks to turn each one into something different. Nothing too tough, just some fun options for them to play with! All of sudden, we had twelve different bowls… no longer the basic round bowls we started with!

Here’s a quick look at them one at a time…

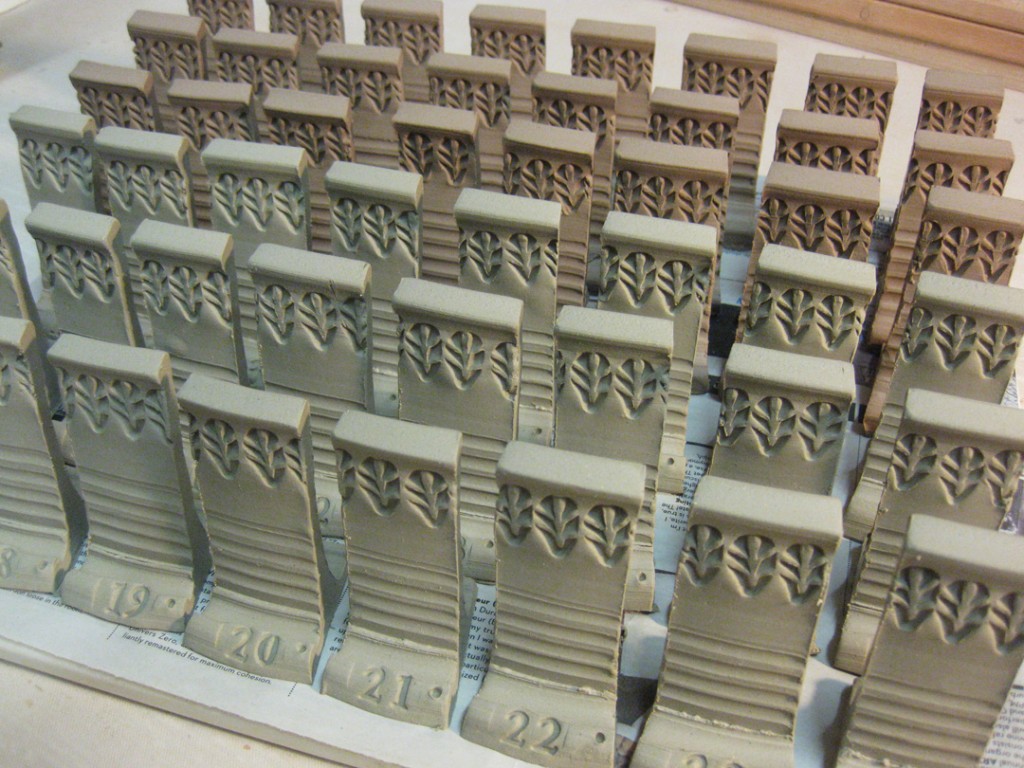

Bowl #1 – The simple round bowl with four fluted accents.

Bowl #2 – The simple round bowl with the top edge flanged outwards. This one will probably get stamped tomorrow night… a few stamps never hurt anyone, right?!

Bowl #3 – A combination of #1 & #2… with the flanged edge and fluted accents combined. Odds are some stamps might hit this one too?!

Bowl #4 – The simple round bowl now with an even wider flange flattened out. That wide flange is screaming for some fun surface decoration, right?!

Bowl #5 – The simple round bowl with a split rim… done with the point of my wooden knife.

Kinda plain now… but this one will be stamped and fluted back together soon.

Bowl #6 – The same split rim technique, but this time pinched back together in places. The little pinch marks kind of bug me right now. For some reason they don’t look quite finished. So I’ll come up with something…

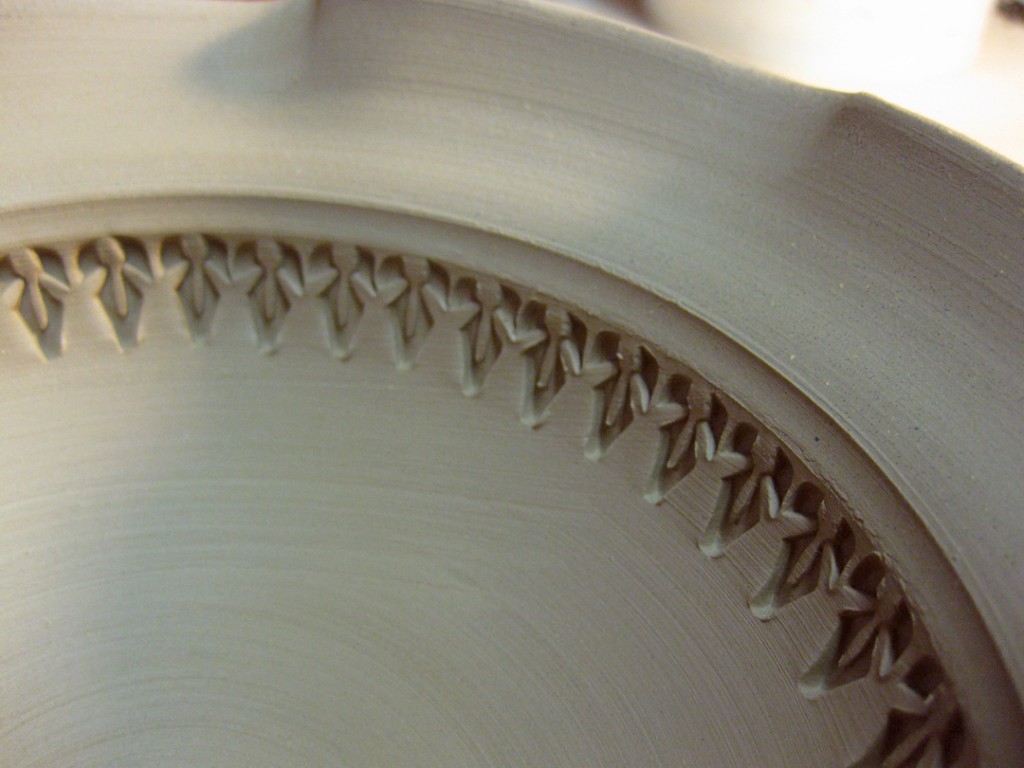

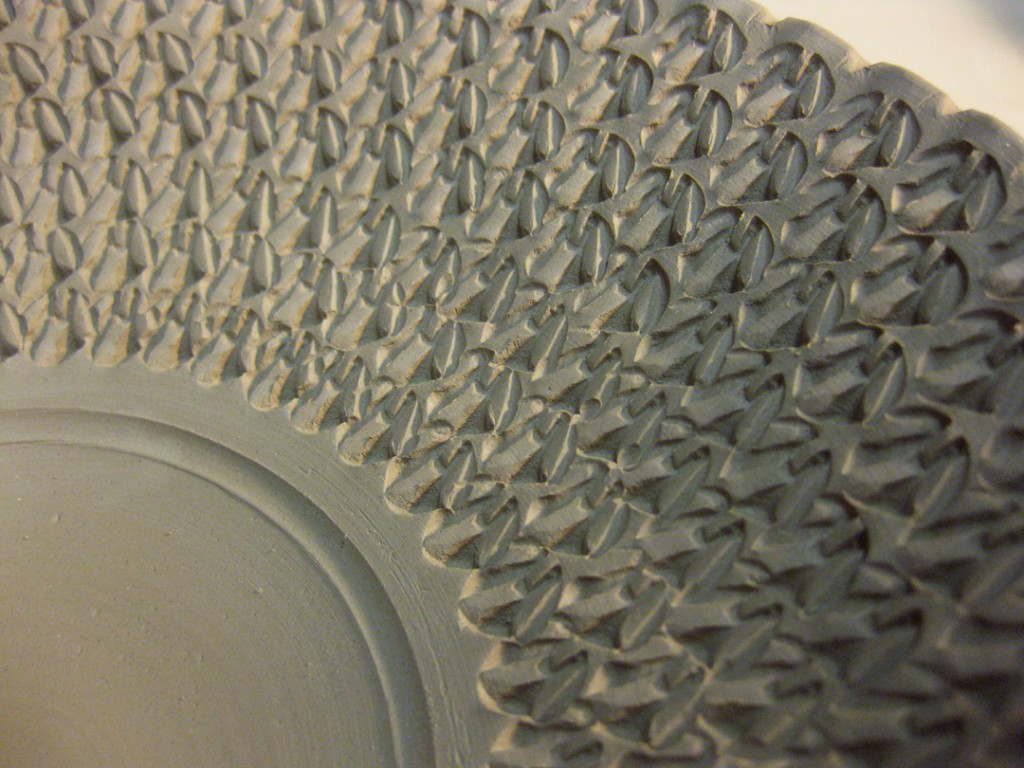

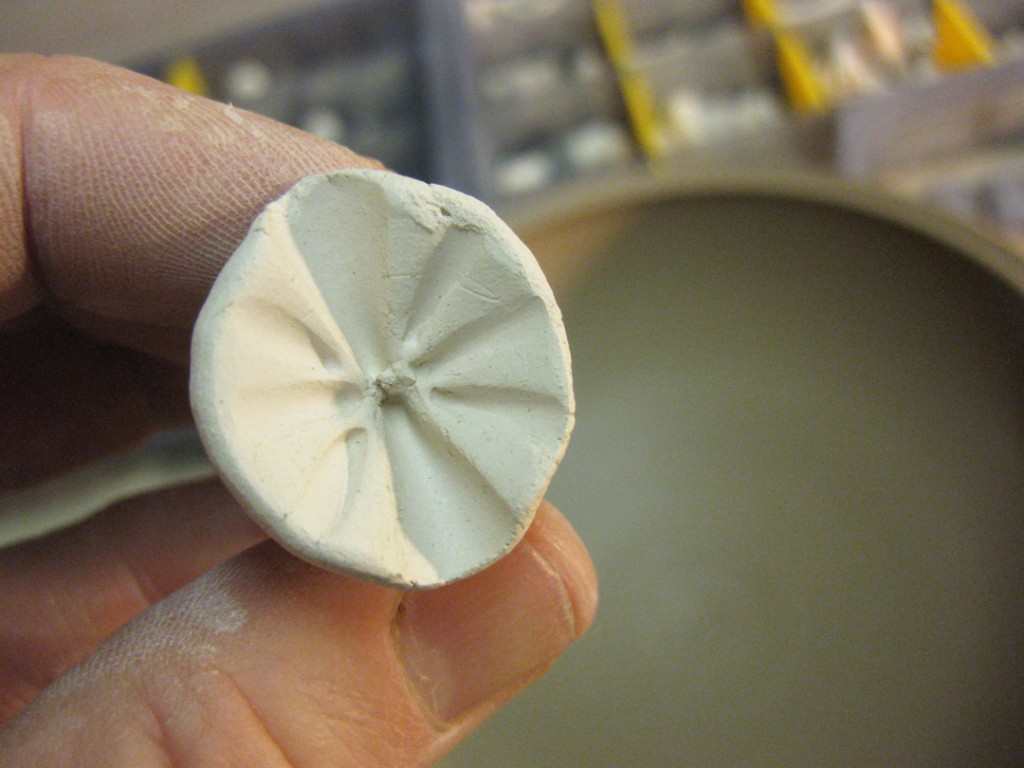

Bowl #7 – The simple round bowl with a small floral design made with a dragonscale tool pressed in a couple times into the freshly thrown bottom. Twelve impressions in case anyone’s counting?!

And then I introduced decorating with colored slip… or in my case, white slip…

Bowl #8 – I coated the interior and then dragged the round end of my wooden knife through it as the bowl was still rotating on the wheel. I especially love how the layer of slip creates some textures inside when dragged through it. The glaze should pool nicely in there somewhere…

Bowl #9 – Then we talked about what would happen if you goofed up halfway… so we stopped the spiral halfway up and finished with banded rings around the top.

Bowl #10 – With the addition of slip, I showed them a way to make Bowl #4 with a decorated flange. I coated it with white slip, and then dragged through it with the rounded end of my wooden knife.

Bowl #11 – After a layer of white slip, I used my curved rib to chatter through it. The challenging part is that it’s a steady combination of chattering speed, wheel rotation speed and upwards movement all at the same time!

Bowl #12 – For the last bowl, I cut out the number five from the newspaper. I stuck it on with water, carefully painted over it with white slip, and then coated the interior of the bowl. I then very carefully peeled out the newspaper 5 to reveal the design.

So now all of the bowls are safely up in my studio – wrapped up for the night. I hope to make it back to the studio tomorrow night to do some more stamping & detailing. And then when they’re ready, I’ll trim them up and send them off to the bisque. And in the meantime, I hope that my students are somehow inspired and ready to play a little more with their clay!