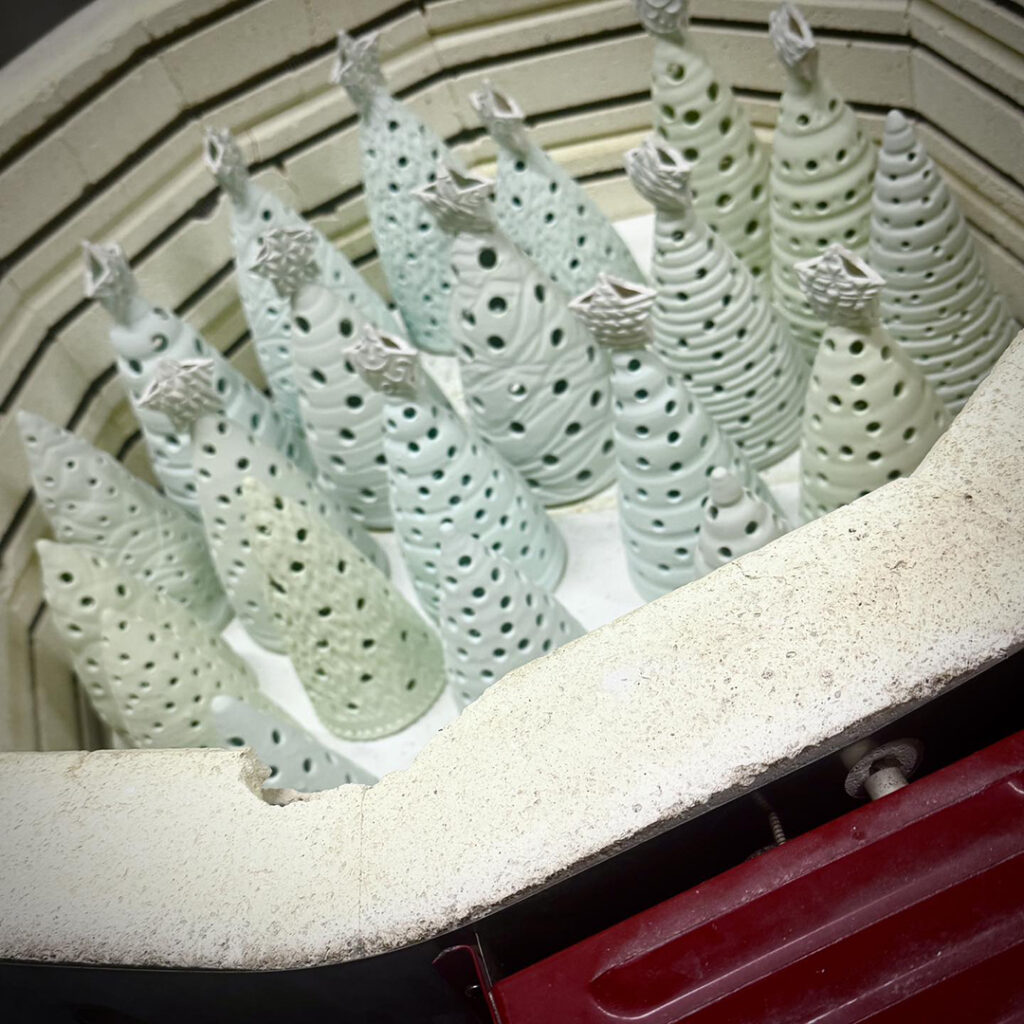

I just unloaded a “quickie-bisque” kiln that I loaded & fired for my Lillstreet Throwdown students. They’re all working hard on their fairy tail themed teapot sets. And I figured their pieces would be “safer” after bisque firing… and it might give them a jumpstart on their glazing?! Especially if they hope to get all their themed sets done by Week 10!!!