Tonight I loaded another electric bisque kiln. With some larger pieces to fit in, it’s always a little tougher to “pack it tight” like I love to do. And sadly, I didn’t have my usual “arsenal” of kiln filler to fill in all the holes!

Kiln Layer #1 – upside-down cake plates, mugs, cruets and ornaments.

Kiln Layer #2 – more upside-down cake plates, bowls, mugs and two tumblers.

Kiln Layer #3 – A short layer of ovals & ikebanas.

Kiln Layer #4 -Bowls, wall pocket vases, mugs, ikebanas, tumblers and an oval.

As I got closer to the top, I did have to do some creative stacking, or should I say “tumbling” to get a little more squeezed in. You know there’s always room for just a couple more… as long as the lid closes, right?!!!

Getting ready for the summer art fairs… and the kids’ flower pots are dry…

so it was time to load a bisque kiln tonight. That’s one of the beauties of terra cotta.

I can do a low-fire glaze firing which also serves as a bisque kiln for my stoneware pieces.

If all goes as planned, the kids’ flower pots will be fired, done and sent to the kids soon!

Kiln Layer #1 – kid’s flower pots, wall pocket vases and some tiles

Kiln Layer #2 – kids’ water drip trays, star ornaments and tiles.

Kiln Layer #3 – one more water drip tray, spoon rests, star ornaments and more tiles.

And yes, I noticed a small glaze issue on the water tray, so I touched it up a smidge!

And here’s my kind of kiln loading…

Kiln #4 – herb flower pots, spoon rests, mugs and a lot of little kiln filler! My favorite!!!

Another good layer, if I do say so myself…

Kiln Layer #5 – mugs, ovals, cruets and some small water drip dishes.

I always love when the kiln finishes up with everything pretty darn close to the top!

So close sometimes that I wonder if the lid is going to close all the way?! Luckily, it does.

Barely.

So that’s another kiln loaded… and now it’s firing. And I still have a LOT more greenware

waiting to go in. Looks like I’m going to be loading another bisque kiln pretty soon?!

So imagine my surprise…

I was working at the “glitter gig” today and we went to the Bridgeport Art Center

to meet a client and do a little pre-site visit for an upcoming event. We were looking

around this really wonderful lofty event space. We happened to pass the washrooms

and I saw these wonderful art installations on the entrance walls. It looked familiar.

And you know how I love grids… multiples of items… and geometric repetition!

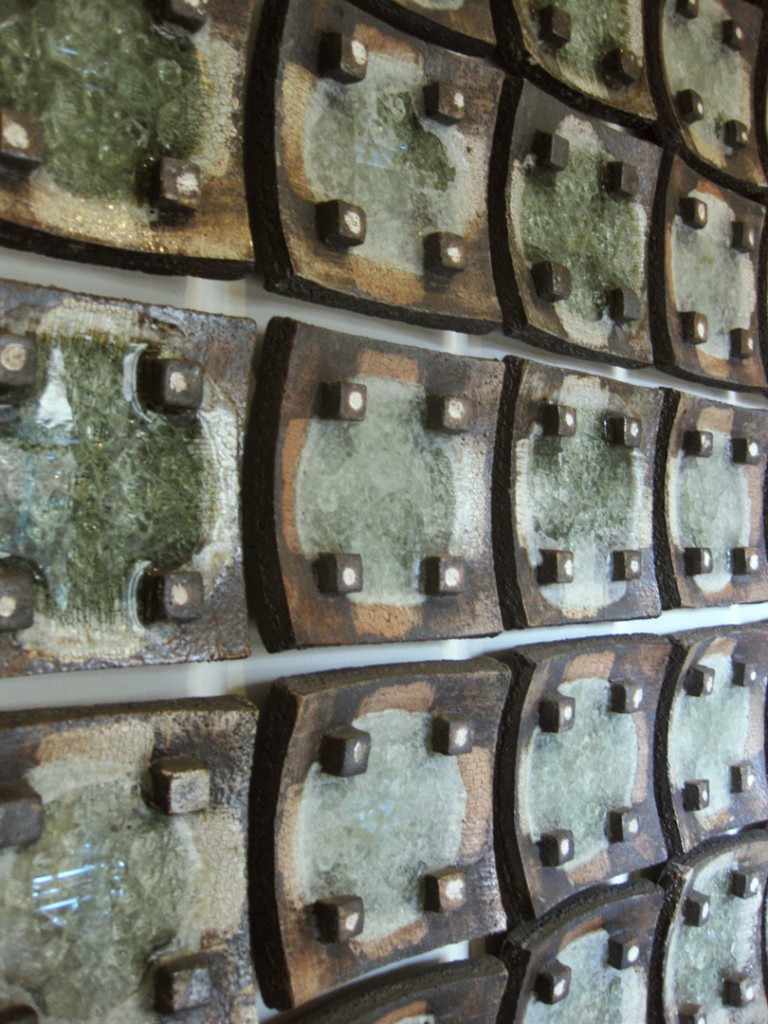

Well, these 50 pieces are basically square plates, with square “legs” on both sides.

I believe they were stacked on each other during the firing. And curved so that the

beautiful glassy-glaze build-up can pool in the center of each plate. Stunning.

We continued walking around the event space, and then I ducked through a side door.

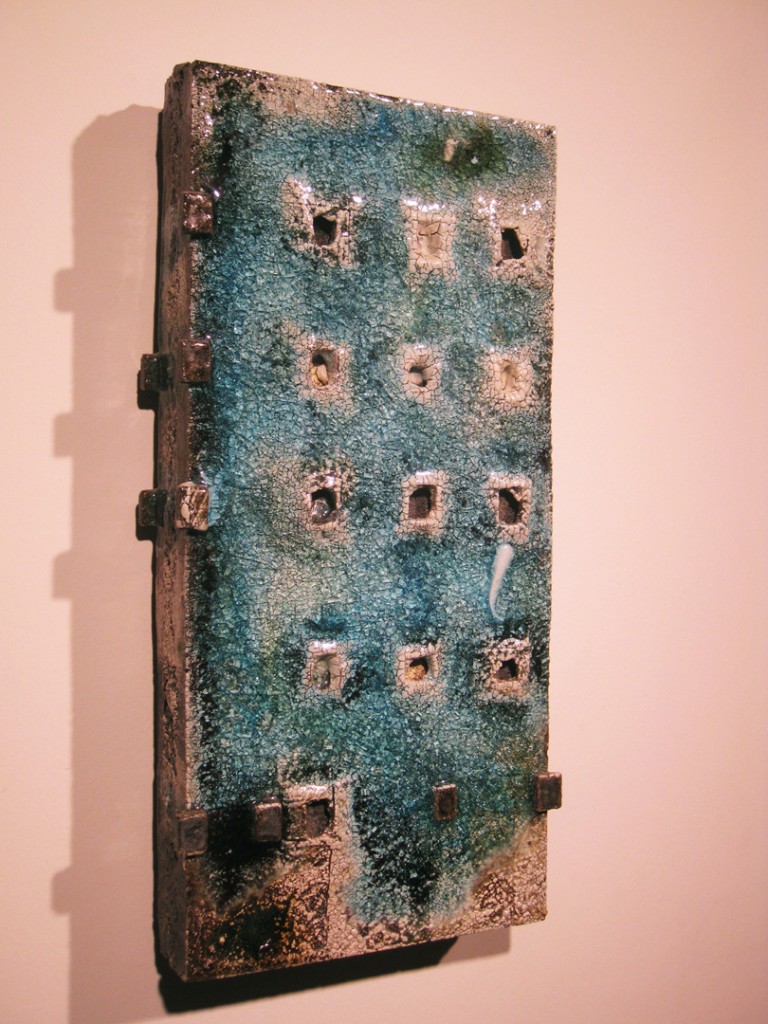

Suddenly I was in a small art gallery. And there were more really cool art pieces on the

walls. And then I realized… these were all made by a friend of mine Jay Strommen.

I had run into him last at SOFA Chicago back in November. We were talking and catching

up with stories about people we know from his time teaching at Lillstreet. We then got on

the topic of his current artworks. Let me just say, Jay is very much an “artist.” He lives

the part… and makes me feel so much like a “craftsman” not an artist. A lot of the “art-speak”

he gives goes right over my head. But it’s fun to hear him talking about what he’s doing…

so passionate, so eloquent, so engaging… and still quite funny!

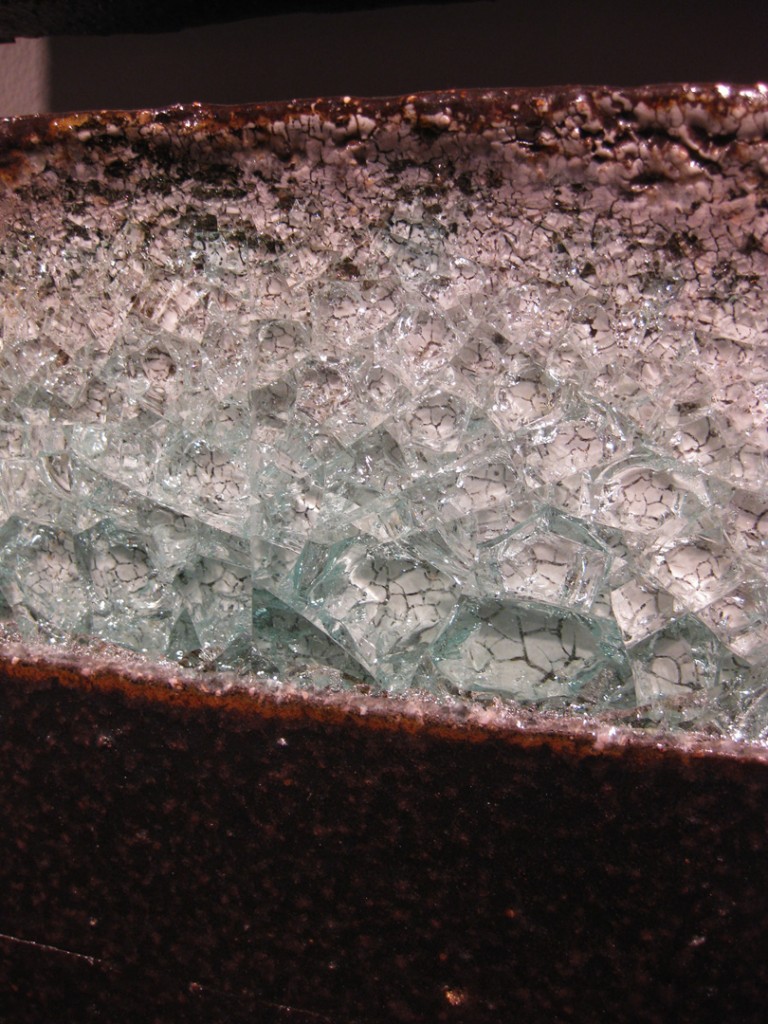

So he then proceeds to tell us that his new work is basically “deconstructing” the entire

ceramic process. Without going into all of the details I don’t quite understand, he’s basically

putting a bunch of clay chemicals, glaze chemicals & other components on a “kiln shelf”

and then melting it all together in a high-fire wood kiln. Of course there’s some very erudite

thoughts behind it, some artistic jargon, some special blah-blah-blah… and I was scared.

Then he tells us that he’s showing at SOFA and that we should go see his work. I was kinda

concerned after all the hype that it was going to be more than a bit crazy. Imagine my

surprise when we got to the booth and his pieces were there hanging on the wall.

And they were incredibly cool!!!

Long story short…

Jay Strommen currently has an exhibit going in the Bridgeport Art Center Gallery.

And since I know that so many of you won’t wander through that same side door I did

today, I thought I would share some pictures of his show!

Now obviously these aren’t all “kiln shelves” that he’s firing onto. They’re actually slabs

of clay that he’s building. But I’m pretty sure that the basic “deconstructed” ceramics

process fired on a kiln shelf principle is still at work here!

And yes, that’s a cone melted onto the surface there… the white hook shaped thing!

If you’re in the Chicago area, be sure to stop by the Bridgeport Art Center to see Jay’s

show. You can also check out Jay’s beautiful website for some images, videos and a lot

of Jayzo’s art speak! Click here to go to Jay’s website… www.JayStrommen.com

Here’s a sneak peek into my recent soda kiln. It’s always such fun surprise to unbrick

the door and see what’s waiting for you inside! So you take out the bricks one-by-one

revealing what’s inside layer by layer. When they’re all gone, the kiln is wide open…

and ready for some quick photos before packing it all up!

As I unloaded the kiln, most of the pieces go straight into crates & boxes so I can get them

home. Along the way this time, I stopped and took a few more photos than normal to share.

Nothing too professional, no graduated gray background… just some quick snapshots in

the empty spray booth with existing lighting! Like I said, nothing too professional…

Plus, something that photos can’t always show… both sides of some pots! Frequently, the

beauty of a pot is in the holding, touching & fondling. Being able to see the pot from all sides.

Noticing all of the details – both inside & out. So here’s one of my new stamped bowls…

both inside with temoku glaze, and outside with more stamping & flashing slip!

And another bowl… this time squared off with a very light layer of temoku glaze inside

along with some flashing slip on the outside.

And I love when you can see the direction of the flame as it passed the pot during the firing.

Where the slip is orange, the flames hit it and deposited some soda. Where the slip band

is still white, the soda couldn’t quite “hit it” as the flames could wrap around the bowl before

moving on & exiting the kiln. So on this bowl, you can see that the flame hit the left side,

and not so much on the right.

Plus, we also have a new Stoneware clay with Ochre in it at Lillstreet. The clay is darker than

regular stoneware and it fires to a dark chocolatey brown. This is the first “ochre” bowl I’ve

ever fired in the soda kiln. It’s a little more dramatic, a little darker… and the flashing slip

band around the foot ring has a great “directional” flash to it. Kinda likin’ it…

Unfortunately, after emptying the kiln, the work continues. It takes quite a while to scrape

and clean all of the kiln shelves, put on a new layer of kiln wash, clean the fire boxes, sweep

& mop the floor… let alone shlepping it all home at the end of the night! A long evening.

But a great reward to have a full kiln’s worth of pots ready for the Holiday Home Show!

I unloaded my soda kiln tonight and was thrilled with the results.

It’s always a fun “treasure hunt” as you uncover it layer by layer, shelf by shelf.

I got some great colors, a lot of fun flashings… and more importantly, no kiln splats

or chunks in any of my pieces. A very clean firing. I took some photos and hope to

have more time soon to post them! Sorry, you’ll have to wait…

The soda kiln was all ablaze with colors & flames as I was inserting the soda mixture into

the kiln. You gotta love playing with fire! I just turned the kiln off, and I’m always amazed

at the sudden silence. Just a warm, crackling glow. And a treasure trove to be unveiled &

unloaded Monday night!!!

Can’t wait… but I have to as it cools all day tomorrow and most of Monday!

So my handmade studio rolling cart made it safely down to the first floor kiln room.

The masking tape “safety belts” really did the trick again as we traveled down the rickety

freight elevator. Nothing jumped off the cart as we hit every bump along the way.

And then the loading began… an arduous task as I try to pack in everything I can!

The back stack of the kiln always seems to load a lot faster. Not only because it’s only

one shelf deep, but I think it’s also that there’s a lot of work to choose from. Later on,

your searching and hoping for that perfect sized piece to fit that precise spot.

I finally squeezed in pretty much everything I possibly could. It took hours!

It’s a delicate balancing act as you stack shelves and try to leave enough space so that the

soda vapors can travel through – versus packing it tight to get the most work you can into

the kiln to help justify the kiln & gas fees. So as you can see, I err on the side of packing it

tight. And I love have smaller pieces like ornaments & tiles that make the perfect kiln filler.

Very little of the white, kiln-washed shelf even show after I place hundreds of tiles in the kiln!

After housr of packing the kiln, you still need to bulid the dor brick-by-brick.

It’s very “old-school” but still a lot more fun than a new-fangled metal door!

So once I have it closed up, I turn it on low for maybe 15 minutes while I’m gathering my

things from my studio. As I’m ready to leave for the night, I turn off the kiln and close the

dmaper to try and hold in some heat. As I know that it’s just a few short hours until I’ll be

back to start the firing early tomorrow morning!

My bisque kiln from last night was still warmer than I would like.

So I decided to let to cool longer and dive into glazing some pieces from an earlier kiln!

I generally start by painting a lot of temoku glaze into all of the stamped impressions.

And then, once the glaze is dried, I take a moist sponge and wipe off the top surface

so that the temoku glaze stays inside the stamped impression – but not on the surface.

I love how the inlaid glaze really shows off the pattern of the stamp, instead of covering

& obliterating it with too much glaze!

But don’t think that they’re done. Oh no, I’ve got a lot of work to do on them first.

Liner glazes, sprayed accents, wadding, etc. So there’s still a lot to do… and even more

coming out of the bisque kiln tomorrow night. Not a lot of time to get everything done.

It’s my plan to load the soda kiln on Friday evening, and fire all day Saturday!