Last night was my favorite demo of the session!

Bowls on purpose. And then decorating them all to be one-of-a-kind pieces!

I try to do it every session showing my students how to “make a bowl on purpose” instead of making a “cylinder gone bad.” Once they learn how to make a “real” bowl, I have them all go back to practice while I throw a bunch of basic bowls quickly. I then call them all back to watch the decoration process. All fifteen bowls looked pretty much the same… plain & round. Hopefully my students picked up a few tricks last night. And if nothing else, I hope it gave them some encouragement to play with their clay – and to do something to it AFTER the wheel does all the work making it round.

Bowl #1 – Plain & simple with a slight spiral in the center.

Bowl #2 – A twice twisted & fluted rim.

Bowl #3 – And if two twists are good, eight might be even better!

Bowl #4 – A flared flange makes the bowl shorter & wider.

Bowl #5 – A wider flange for more presentation… less food.

Bowl #6 – Not every bowl needs to be round. Like this square one!

Bowl #7 – Using a simple dragonscale tool, I impressed this flower one petal at a time.

Bowl #8 – A decorative split rim with eight pinched sections.

Bowl #9 – Another split rim with ore pinches for a decorative, almost-braided look.

Bowl #10 – A split rim pinched together… bent inwards,, and bent outwards like a lotus flower.

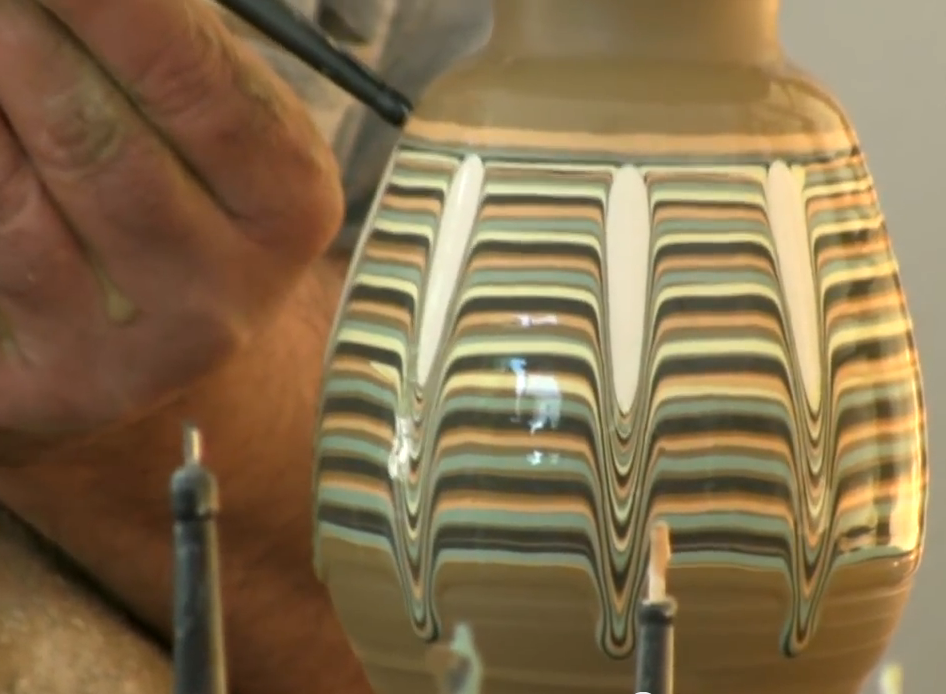

After a simple explanation of colored slips

Bowl #11 – A simple spiral dragged through the slip to reveal the clay color below.

Bowl #12 – Banded rings with a squiggled section in the middle

Bowl #13 – Rhythmic chattering through the colored slip.

Bowl #14 – A “stencil” letter cut out from the newspaper. Slipped over, then pulled out.

Bowl #15 – A two-color ombre effect… but I couldn’t resist, and I “had to” drag a spiral through it.

So now all fifteen bowls are up in my studio…

Wrapped up overnight so I can keep working on them later. Sadly, all of my tables are full of drying pieces… so last night’s bowls are under plastic ON THE FLOOR!!!