Here’s a sneak peek into my recent soda kiln. It’s always such fun surprise to unbrick

the door and see what’s waiting for you inside! So you take out the bricks one-by-one

revealing what’s inside layer by layer. When they’re all gone, the kiln is wide open…

and ready for some quick photos before packing it all up!

As I unloaded the kiln, most of the pieces go straight into crates & boxes so I can get them

home. Along the way this time, I stopped and took a few more photos than normal to share.

Nothing too professional, no graduated gray background… just some quick snapshots in

the empty spray booth with existing lighting! Like I said, nothing too professional…

Plus, something that photos can’t always show… both sides of some pots! Frequently, the

beauty of a pot is in the holding, touching & fondling. Being able to see the pot from all sides.

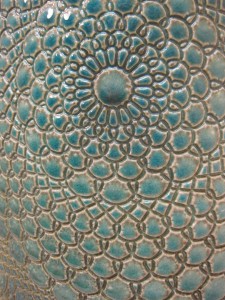

Noticing all of the details – both inside & out. So here’s one of my new stamped bowls…

both inside with temoku glaze, and outside with more stamping & flashing slip!

And another bowl… this time squared off with a very light layer of temoku glaze inside

along with some flashing slip on the outside.

And I love when you can see the direction of the flame as it passed the pot during the firing.

Where the slip is orange, the flames hit it and deposited some soda. Where the slip band

is still white, the soda couldn’t quite “hit it” as the flames could wrap around the bowl before

moving on & exiting the kiln. So on this bowl, you can see that the flame hit the left side,

and not so much on the right.

Plus, we also have a new Stoneware clay with Ochre in it at Lillstreet. The clay is darker than

regular stoneware and it fires to a dark chocolatey brown. This is the first “ochre” bowl I’ve

ever fired in the soda kiln. It’s a little more dramatic, a little darker… and the flashing slip

band around the foot ring has a great “directional” flash to it. Kinda likin’ it…

Unfortunately, after emptying the kiln, the work continues. It takes quite a while to scrape

and clean all of the kiln shelves, put on a new layer of kiln wash, clean the fire boxes, sweep

& mop the floor… let alone shlepping it all home at the end of the night! A long evening.

But a great reward to have a full kiln’s worth of pots ready for the Holiday Home Show!