With “Art In The Barn” just a week away, I’m working extra hard to make plenty of new work. So while I’m firing a soda kiln full of new work, I decided to glaze & load another kiln. Why not do two kilns at the same time?!!! I’m stuck in the studio all day firing… why not tackle another project?! I had already cleaned my studio… so more is more. And the more I have in Barrington next weekend, the more I can sell right?

My past couple Cone 6 firings have had mixed results. More pinholing & shivering that I would like. I was hoping that Cone 6 would be an easy firing with quick, colorful results. Not so far… still trying to find the right solution. So this time, I’ve added pyrometric cones top & bottom to double-check that the kiln is reaching temperature evenly. I’ve also put on a much thinner “sprayed” layer of glaze on most of the pieces. And one dipped to see if that makes a difference. Fingers crossed that something turns out okay. And that we might find some “answers” along the way!

Kiln Layer #1 – spoon rests, tiles… and a serving bowl that I’m re-firing!

Kiln Layer #2 – two bowls, mugs and more tiles.

Kiln Layer #3 – two more bowls, spoon rests , mugs & tiles.

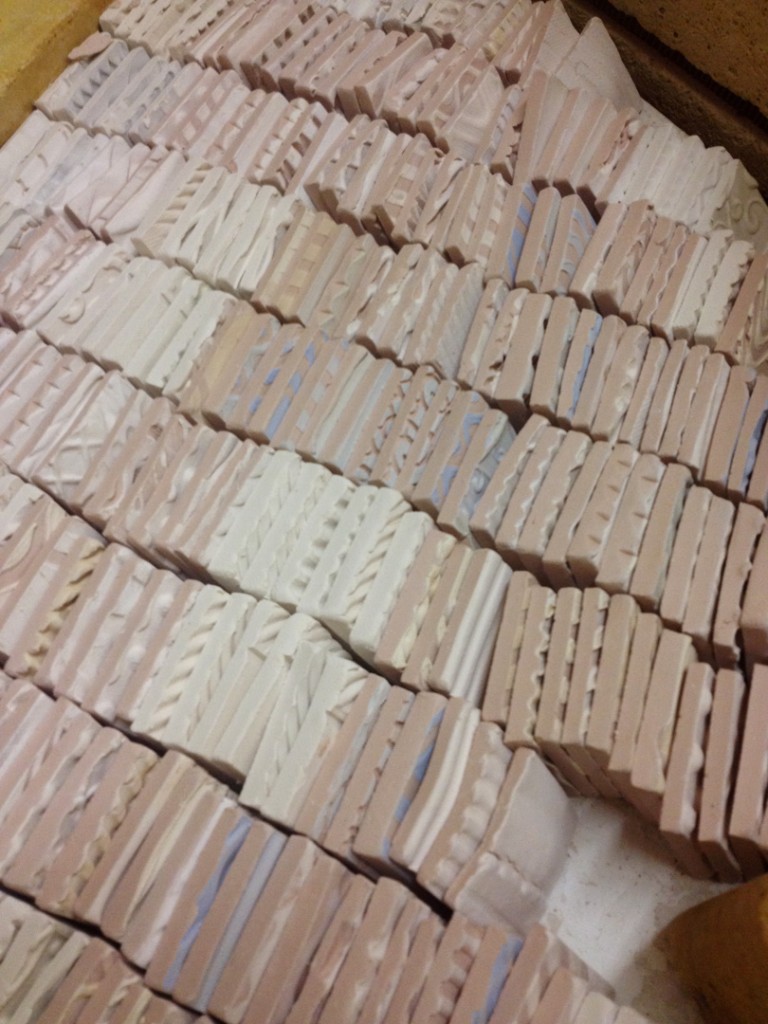

Kiln Layer #4 – bowls, tiles and more of my “Relic Rattles.”

Kiln Layer #5 – textured fortune cookies.. and two tiles that didn’t fit on the layer below!