With my soda kiln scheduled for this coming Saturday, I knew that I needed to crank out some last minute work… and squeeze it all into one last bisque kiln. Sure, it might not be my finest job of packing a tight kiln, but all of the little “filler” pieces went into the bisque kiln a couple days ago! So for now, I just knew that I had to get things bisqued quickly so I had some time to glaze & wad before Friday night’s soda kiln loading.

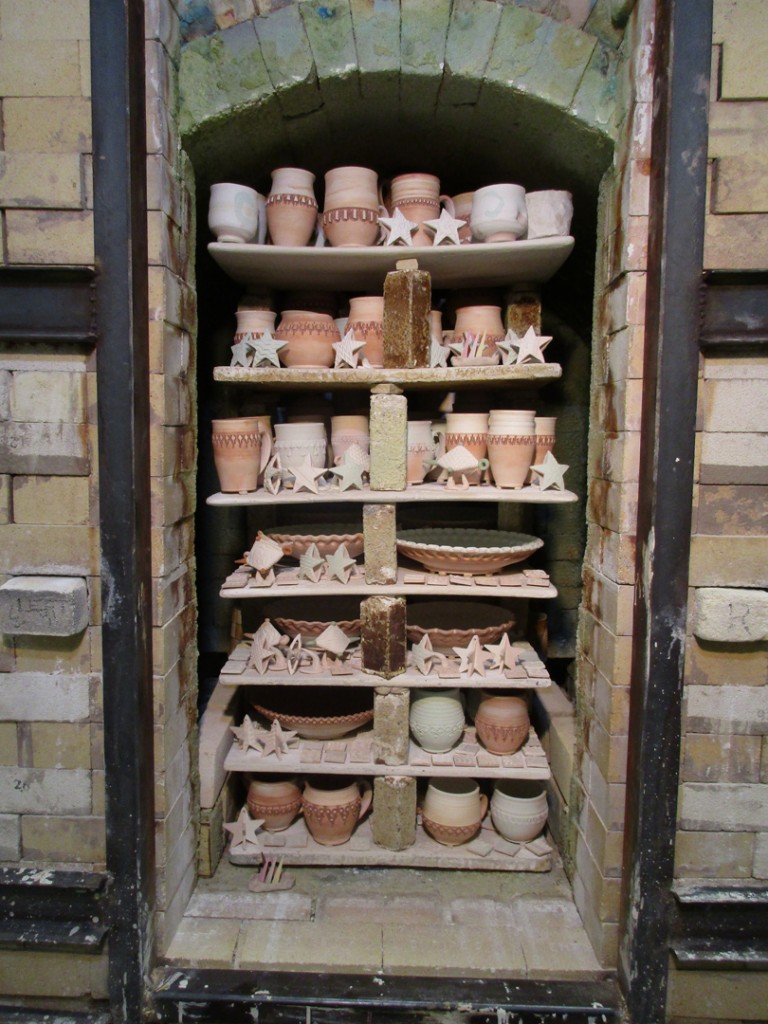

Kiln Layer #1 – lidded jars, small pitchers, mugs and some ornaments.

Kiln Layer #2 – two stamped platters, two bowls… and some more ornaments!

Kiln Layer #3 – half of the third layer was filled with stacked stamped bowls.

Kiln Layer #4 – porcelain mugs, bowls and some stacked pieces to fill the height.

But, oh wait… there’s a gaping space on the top of the kiln!!! We can’t have that.

You know how much I LOVE a well-packed kiln. I wouldn’t be able to sleep if I left that empty space like that!

Gotta make something quick to fill that space!!!

Save

Save

Save