Looks like I’ve got some trimming to do…

Gary Jackson: Fire When Ready Pottery

A Chicago potter’s somewhat slanted view of clay & play |

So I saw a random post on Instagram over the weekend about a basic potter’s challenge… for newbies & more advanced throwers. One pound of clay, perfect cylinders, four inches tall with just four pulls. Not a bad way to start the morning…

After a couple handbuilding challenges, it was time for my THROWDOWN class to get back on the wheel. This time it was “tallest” wheelthrown cylinder with two pounds of clay! With a nice even rim… no pinching, stretching or adding onto the top to make it taller! Congrats to Claire, Katie & Alex for their tallest cylinders!

Another batch of cylinders working their way towards becoming mugs! Too wet to stamp now… but I feel some “shamrock stamps” might just be headed their way!!!

So it’s Monday… and it feels great to be back in the studio being productive again! Getting back into the groove!!! It was a long break, so it feels great to have my hands back in the clay! And to “practice throwing” again… as the new session of classes starts tonight at Lillstreet!!! And I don’t want to look too “rusty” for my Intermediate Wheel students tonight!!!

Thrown on Tuesday night, and trimmed tonight… just minutes before my SURFACE DECORATION class. I can’t wait to see what my students do with these “blank” cylinders… as tonight’s technique is mishima!!! More photos to come…

Cylinders trimmed & drying… wait, WHAT?!

Perfectly smooth? No stamping? No texture? No patterns? Don’t panic… I kinda have a plan for these! You know how I love a good plan! More soon…

The next challenge for The Pottery Olympics was to throw the tallest cylinder on the wheel using three pounds of clay in ten minutes. Sounds simple enough, right?! Except the real challenge was that the team members had to switch positions taking turns throwing every minute!!! Sixty seconds… switch… sixty seconds… SWITCH!!!

All thrown… a very productive day!

Forty cylinders thrown to make forty mugs. The commission isn’t quite that large… but they will be soda-fired so I’m making a few “extras” in case some of them don’t turn out so well?! You know how soda-firing is kinda random… I can only “control” so much!

Last night was the first night of my new Surface Decoration Techniques class at Lillstreet. We started with introductions & overviews… and then started off with our first technique. I pulled out some thick colored slip to add some texture, pattern & color to a few basic bowls & cylinders… and hopefully some fun effects when we get to glazing these pieces!

THICK SLIP BOWL #1 –

I first added a layer of thick white slip on the interior of the bowl. I showed them a few different patterns… spirals, squiggles… wiping & smoothing it back after each one. We “ended” with a spiral in the bottom and a rib-fluted pattern around the rim.

THICK SLIP BOWL #2 –

Pretty much the same technique of Bowl #1… just with a thicker layer of slip. I felt that the rib-fluted edge wasn’t apparent enough the first time. And I like how the thicker slip made it more look more intentional.

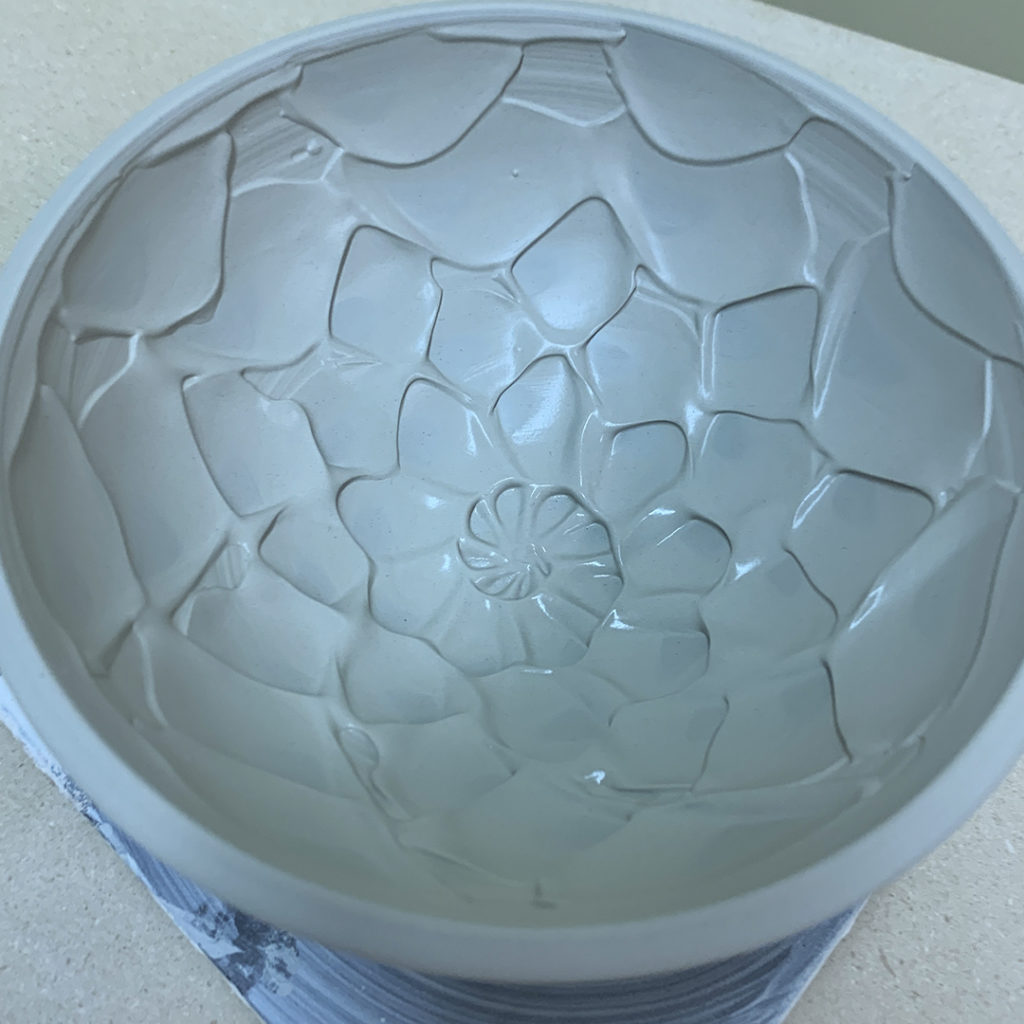

THICK SLIP BOWL #3 –

Another layer of thick white slip, and then a chattered pattern added throughout. I uses a rounded rib, and tapped the slip by moving the rib up & down… and up & out… while the bowl was spinning. The pattern is created by the speed of the chattered tapping, the speed moving up, and the speed of the wheel’s rotation!

THICK SLIP BOWL #4 –

For this bowl we did an ombre’ blend of white & green slips. A simple blending of colors. I feel it still looks kinda plain, so I think there “might be” a little bit of carving to come on this one!!!

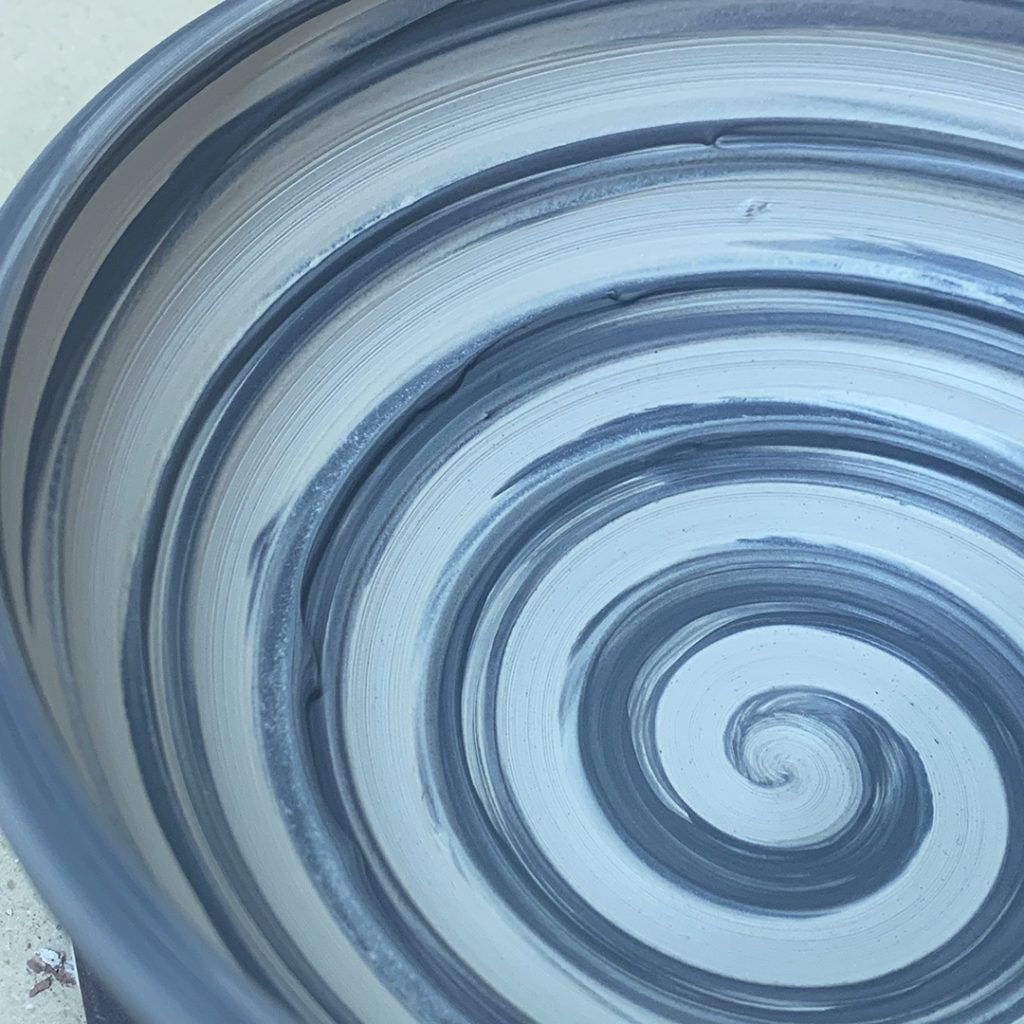

THICK SLIP BOWL #5 –

For this bowl, I “tried” to squirt a perfect spiral of black slip into the bowl while it was spinning. But the slip was a bit too thick and didn’t come out of the bottle smoothly…. spurt… spurt… sputter… glops!!! So then we needed to “fix” that… so I smoothed it out with a rubber rib giving it an uneven black slip surface with some clay still showing through. We liked the marble effect… but it seemed a bit wimpy. So I added a spiral dragged through at the end.

THICK SLIP CYLINDER #1 –

We’ve all seen this technique showing up on our Instagram Feed from Joe Thompson @oldforgecreations… so we decided to give it a go! Not a real success… the slip was a bit too gloppy… there were a few “chunks” in it. But when I squirted it on… and then tapped it down a bit to make the slip move… we did get a lot of “oohs & ahhs” from my students!!! Definitely not as easy as Joe makes it look… but fun!

THICK SLIP CYLINDER #2 –

We decided to try another version of the drippy slip technique. This time with two colors of slip. I tried to add a “stripe” of green slip down the side of a squirt bottle… and then add more white slip “on top” of the the green. Idea being that when squirted out, you would get more white slip with a little undercolor of green. Kinda gloppy… but not bad for our first attempts! I’m pretty sure I’ll be leaving this technique for Joe who perfected it for us!!!

THICK SLIP CYLINDER #3 –

This time I covered the exterior with thick white slip, and then dragged a rounded rib across the outside to make these horizontal ribbed grooves.

THICK SLIP CYLINDER #4 –

For this cylinder, I tried again to make a “perfect” spiral going down the outside with a squirt bottle filled with slip. But again, it sputtered & spurted. So I draged a rubber rib across it and it surprisingly made this marble-clay-like effect. Done... and so much easier that actually making colored clay and throwing with two colors in a marbled clay!

THICK SLIP CYLINDER #5 –

Because I was having a bit too much sputtering & spurting with the squeeze bottles, I added some water to them and shook them up. But maybe a bit too much water?… as it wouldn’t hold its shape & thickness any more. So when I squeezed the white on the side at the top, it just ran down and covered the exterior. So I tried adding some green, and it too ran down and covered the entire exterior. So I tried again, and again, and again… each time trying to vary the amount of slip squirting out. At some point, my layers started to give me a groovy-drippy tie-dyed look… so I stopped!

And for now they’re all in my studio under wraps.

Today I’ll open them up and do a bit of details & refining.

|

Gary Jackson: Fire When Ready Pottery

Lillstreet Studios ∙ 4401 North Ravenswood, Chicago, Illinois 60640 ∙ 773-307-8664 gary@firewhenreadypottery.com |