Okay, so I’ve mixed up a few. Dipped a few.

And now the results are starting to come back from the kiln. These were the first four tests… which were designed to be cone 6 glazes, but I thought I would try them in a cone 10 kiln as well. You never know when it might work in both, right!? You can always dream…

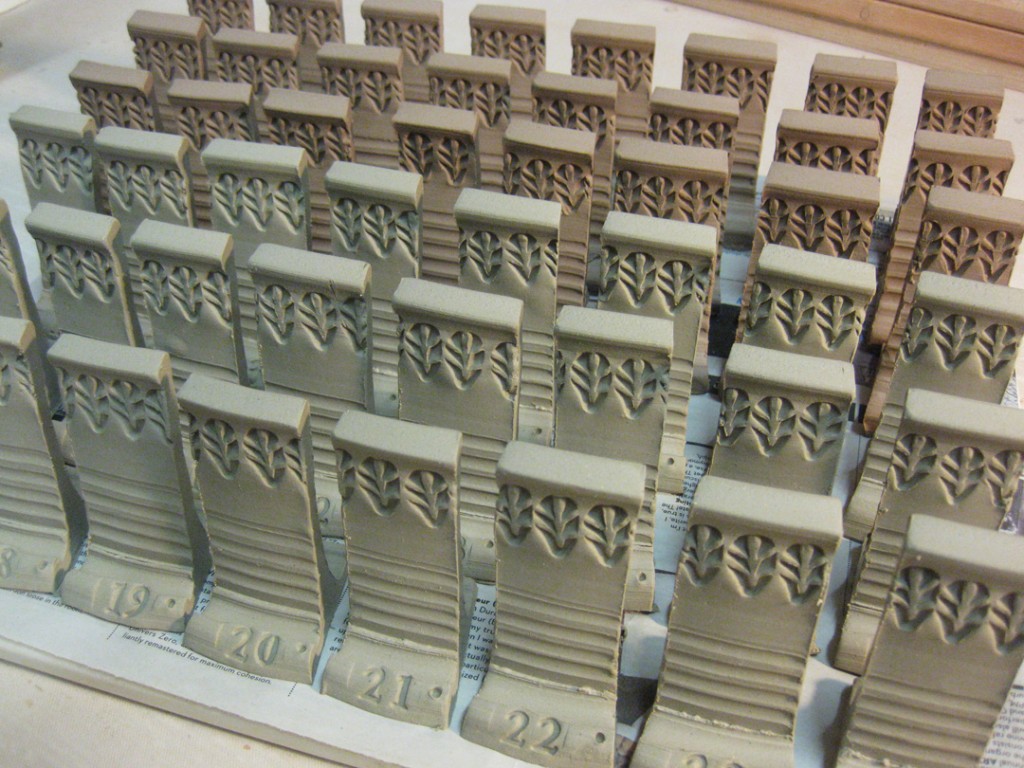

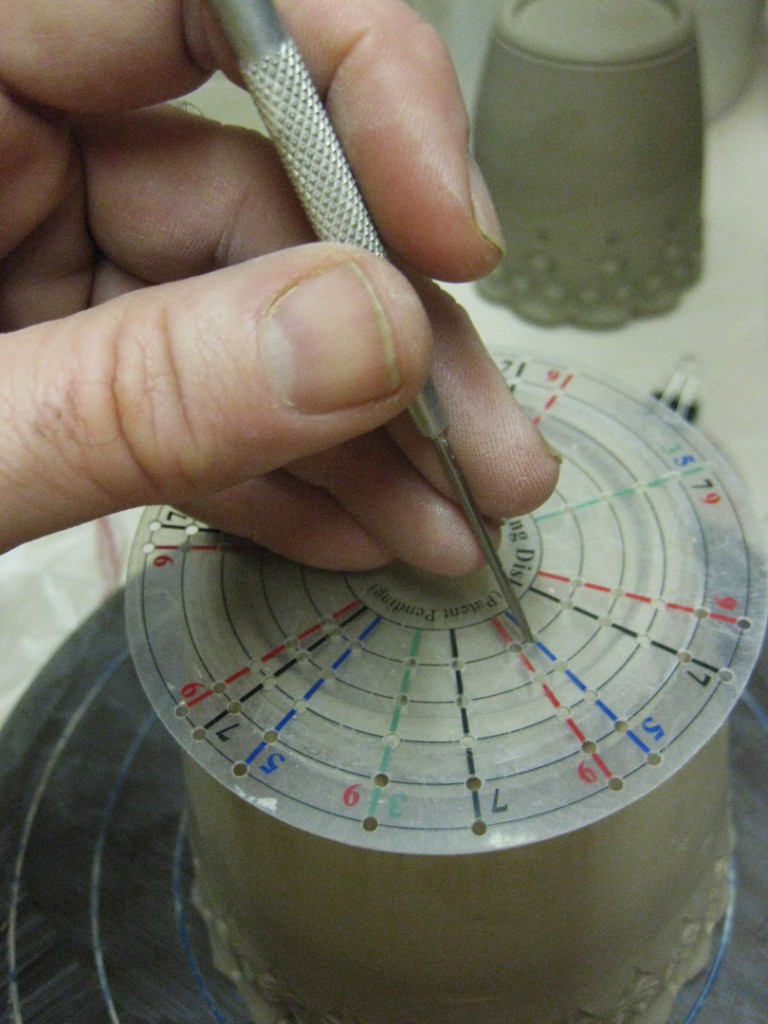

So here’s the deal… I’m looking fro some glazes that cover well, accentuate my stamping and maybe even do some really cool breaking or color variation along the way?! So I’ve decided to try a few new glazes. And if I need to start a little cone 6 firing for an added pop of color in my inventory, then so be it.

Like I said, these are cone 6 glazes fired in a cone 10 reduction kiln. I’m pretty pleased by the results. Encouraged by these results. And hopefully that the cone 6 tests will look even better – after being fired in the kiln they were intended for! I’m hoping to get the cone 6 samples back later this week!

In the meantime, if anyone out there has some good cone 6 glaze recipes that you would be willing to share, send ’em my way! Again, I’m looking for good colors that break well on stamped textures.