Tonight I started with trimmed pots… trimmed, smoothed, refined… still leatherhard.

But if these little cylinders are going to become the little herb flowerpots as planned…

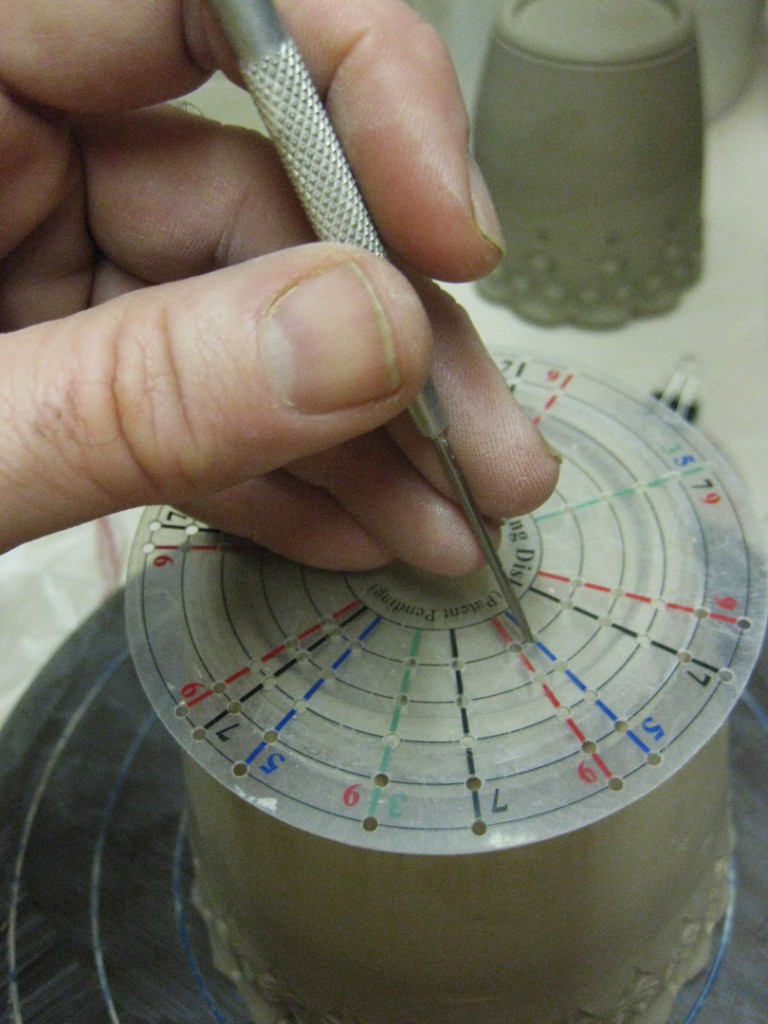

they still need some drainage holes. So I started by marking the placement of where

the drainage holes will be placed. Sure, I could do it freehand… but why?!

When you’ve got some great little tools which practically do it for you?!

These great little disks from MKM Pottery Tools are a huge help when trying to divide into

equal segments. And here’s the cool part, they give you two disks. One for an even number

of segments, and another for an odd number of segments. Plus little holes on the disks that

you can poke through to mark your pots. I’ve got the smaller 4″ disks, but they also sell a

larger 15″ disk for larger pots & platters. Click here for more info on MKM Pottery Tools.

Once the hole placements are marked… it’s time for the power tools!

Sure, I could use a small manual hole punch. Sure, I could carve through by hand.

But why do all that when an electric drill can do the trick much quicker & cleaner?!

Just insert the drill bit of your chosen diameter and drill away… carefully!

Of course you need to make sure your pots are still a good stiff leatherhard. If they are

too dry there’s more of a risk of cracking the pot. If you clay is too wet, it will just kind

of gunk-up the drill bit. Go for stiffer-leatherhard. You’ll be glad you did.

So once the drainage holes were done, I added some colored slip accents into a few of the

stamped impressions. And since these little herb flower pots are going to be soda-fired, I

used a couple different colors of flashing slips. These slips may appear to be whites & beiges

now, but when they’re fired the slip will hopefully turn into shades of oranges & yellows!

So now they’re all drilled… slip decorated… signed…

And drying…Â Next up?… I still need to throw the water saucers that will go under them!

Great planters. You are definitely on a huge production kick. Is there a reason you are not notching the foot ring to let the water out? Also, I was showing off your photos for “Empty Bowls” at a meeting last night and everyone loved them. They asked if you could come to Cleveland to throw some bowls with us. You are more popular than you think. Consider that an invitation, if you are ever in the neighborhood.

ALLEN –

Yes, it’s winter in Chicago. So the more time I spend in the studio now, the less time I’ll need to be in the studio this summer when it’s beautiful outside and I want to play! Plus, once art fairs & summer camps kick in, it always seems to affect my studio time. So yes, you are correct. I’ve been trying to build up the inventory.

As for the “missing” notch on the planters… I don’t think they really need them. It’s just water coming out and that will seep wherever it wants too. Plus, the little dishes I’m going to make to go under them will have some pretty deeply-indented spirals. So the pot sits on the top edges of the spiral, and the water can go into the indentations.

Cleveland, huh?! I’ve actually never been to Cleveland… although I hear “Cleveland Rocks!” If I’m ever headed out your way I would love to stop by and throw some bowls with you guys. I’ll keep your invitation in mind, thanks. Maybe me and my bike need to head East a bit this summer?

How did I not know about those guide disk tools? Thanks for posting about them. It seems like an obvious tool to have around, in retrospect… now that I’ve already made the pots I needed them for. Sigh.