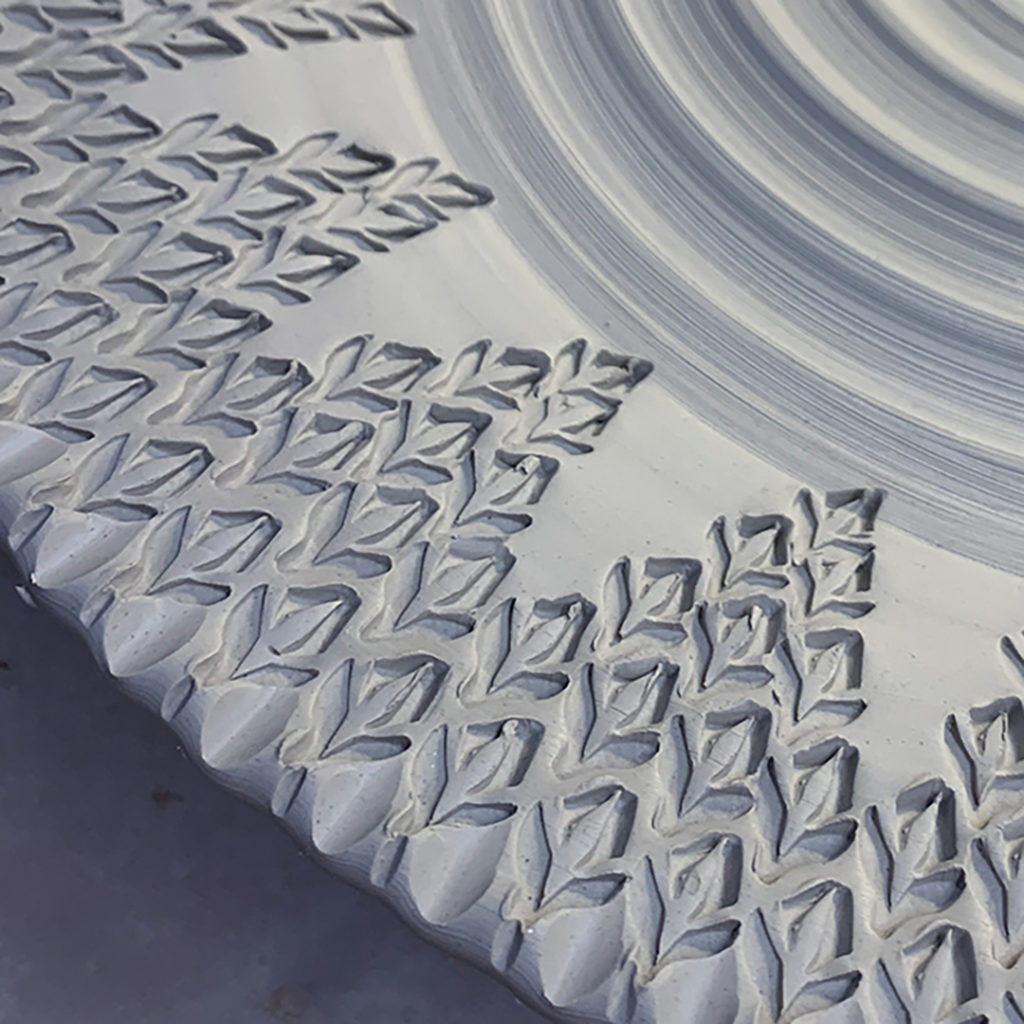

After teaching class this morning, I pulled some long handles and let them hang off the edge of my wedging table to stiffen up. For mugs I like to flip them to set the curve of the mug handles… but for these “basket” handles I wanted them a bit thicker, longer & straighter!