Just finished assembling my “class demo” casserole… as my Intermediate Wheel class has been focused on casseroles this session. No one ever said a casserole has to be oval, right???

Gary Jackson: Fire When Ready Pottery

A Chicago potter’s somewhat slanted view of clay & play |

Just finished assembling my “class demo” casserole… as my Intermediate Wheel class has been focused on casseroles this session. No one ever said a casserole has to be oval, right???

One last thing before they dry… I added a layer of colored flashing slip to my batch of hybrid mugs. At some point, these mugs will be soda-fired so they should change to shades of oranges & yellows during the atmospheric firing.

Another 10×10 CHALLENGE… restocking “the basics” for my summer art fair inventory.

Today by throwing more than ten spoon rests before 10:00am!

Accents painted & done! These mugs will be bisqued & then soda-fired. So they will not get any glaze on the exterior except for a little tenmoku in each stamped impression. The raw clay & colored flashing slips will transform in the kiln due to the firing process creating a nice “glazed” shine & flashing effects. Each one totally different based on where the flames hit it during the soda firing.

Handles attached… we now “officially” have mugs!!!

I’m a firm believer that by definition a “mug” needs a handle!

While some of my students might try to convince me otherwise… I’m not buyin’ it!!!

Another day pulling handles & making mugs!!!

My favorite thing to make… MUGS!

And for now they’re all going back under plastic so they can dry slightly to leatherhard clay. Then it’s trimming & adding of handles… and soon enough, these will become mugs!!!

My first 10×10 CHALLENGE of the New Year! And starting with my favorite thing to make… MUGS of course!!! More than ten thrown before 10:00am! Giddy-up!!!

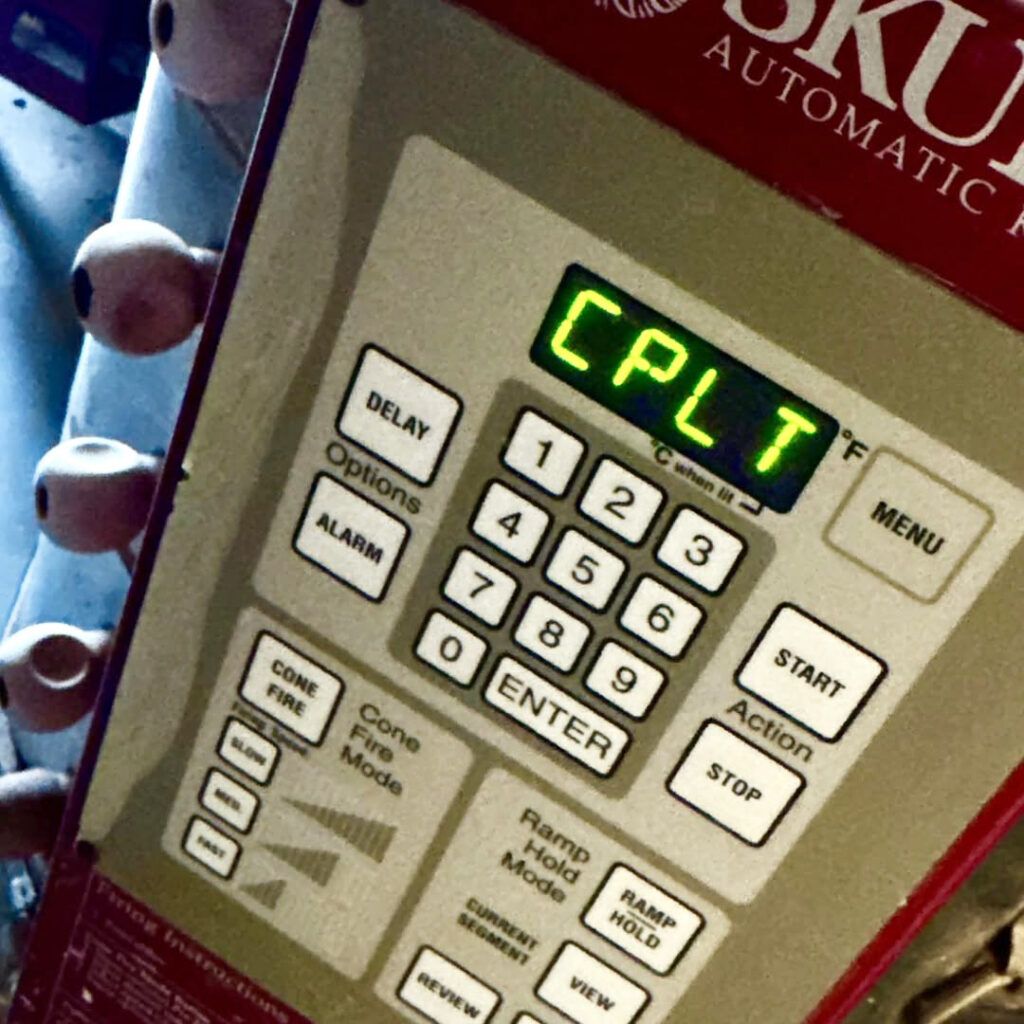

One last kiln to unload before this weekend’s pottery sale!

Just in time for my SECOND HOLIDAY HOME SHOW!

C’mon by!!!

Just finished waxing a LOT of bottoms… getting ready to do some glazing. I hoping to get all of this… most of this?… some of this???… glazed & fired before this weekend’s SECOND HOLIDAY HOME SHOW!!! A bit of quick replenishing goin’ on here!!!

|

Gary Jackson: Fire When Ready Pottery

Lillstreet Studios ∙ 4401 North Ravenswood, Chicago, Illinois 60640 ∙ 773-307-8664 gary@firewhenreadypottery.com |