Hybrid mugs moving along! Trimmed the bottoms today on the wheel. You know how much I LOVE trimming & a good footring!!! Gives everything a sense of style & refinement.

Gary Jackson: Fire When Ready Pottery

A Chicago potter’s somewhat slanted view of clay & play |

Hybrid mugs moving along! Trimmed the bottoms today on the wheel. You know how much I LOVE trimming & a good footring!!! Gives everything a sense of style & refinement.

It’s been a productive afternoon assembling these “hybrid” mugs… wheelthrown & handbuilt combos. There’s still a good amount of work to do on them… refining, trimming, adding handles, drying, firing, etc. But this feels like a good start. It’s always great seeing these “hybrid” mugs come together!

It’s been fun using some of my new handrollers today from MKM Pottery Tools. I’m generally a more “geometric” kinda guy when it comes to patterns & textures. But I will say I’m pretty excited about some of these new rollers that a more “illustrative” pattern on them. We’ll see how it goes with more rollers for more patterns!!!

Here we go again… making some textured slabs with my new MKM Pottery Tools handrollers. Fun patterns with crisp clean edges… coming soon to a new batch of “hybrid” mugs! This is the handbuilding part… soon to be added to the wheelthrown part! Thus… “HYBRID” mugs!!!

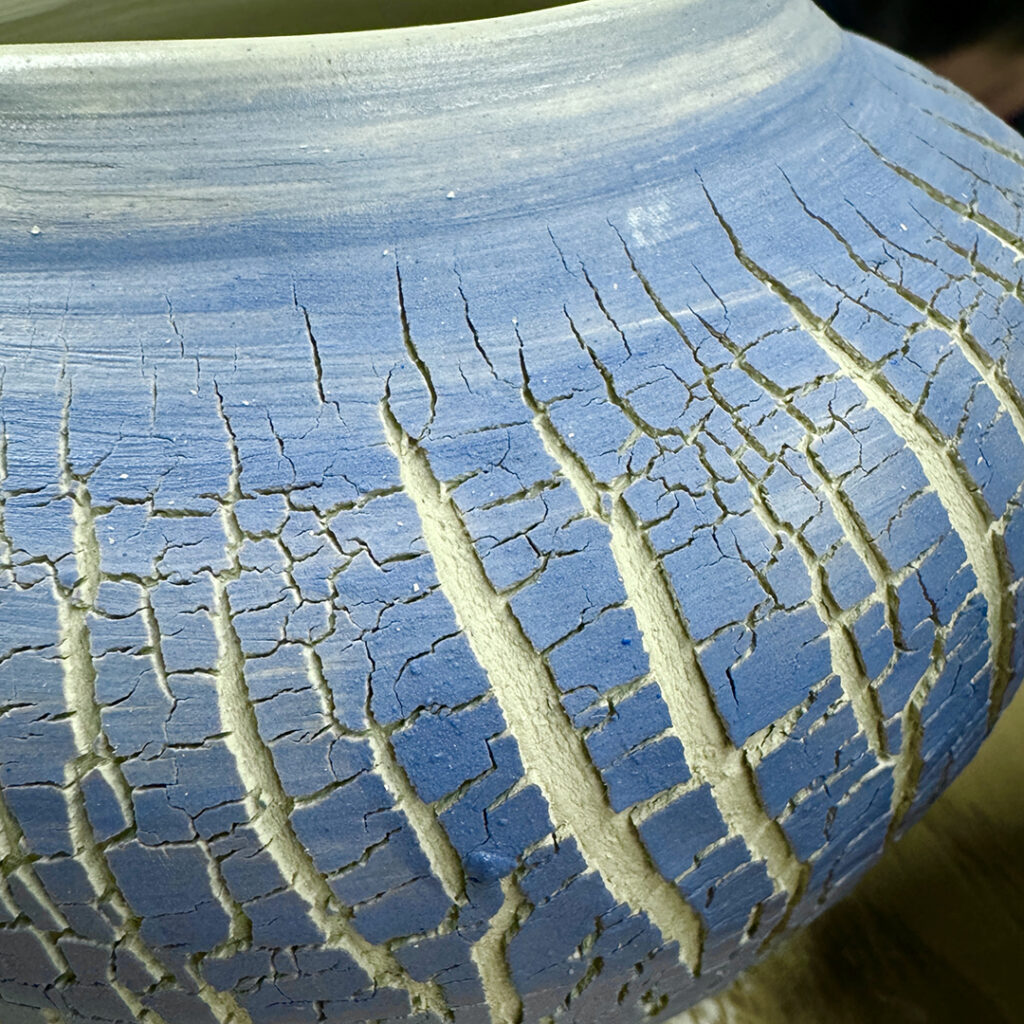

Last night in my SURFACE DECORATION class, we played with some different slip colors mixed with a sodium silicate solution to help us create these wonderful crackled surfaces on our wheelthrown pots!!! Exciting as every one is different every time!!!

Time for some stamping… giving the spoon rests some decorative edges.

Gotta make those sloppy spoons look good while you’re cooking, right?!

ugh.

You know it’s my least favorite thing to do… but at some point, a little glazing has got to happen.

But first… I get to apply wax to all of the bottoms to make my glaze clean-up easier later.

I do enjoy waxing bottoms… glazing not so much.

After trimming the bottoms to form a good footring, I let these dry a bit more before drilling drainage holes… with my POWER DRILL!!! The fastest & cleanest way to make a lot of holes fast. And who doesn’t like using power tools on their pottery?!

Just adding a few accents of colored flashing slips on this latest batch of stamped mugs. The slip colors will change dramatically when fired in the soda kiln… more colorful with flashing effects from the flames!

Handles attached… another batch of mugs made! I’m planning on soda-firing these in the future, so I think they might still need some colored flashing slips before I call them done & let them start drying.

|

Gary Jackson: Fire When Ready Pottery

Lillstreet Studios ∙ 4401 North Ravenswood, Chicago, Illinois 60640 ∙ 773-307-8664 gary@firewhenreadypottery.com |