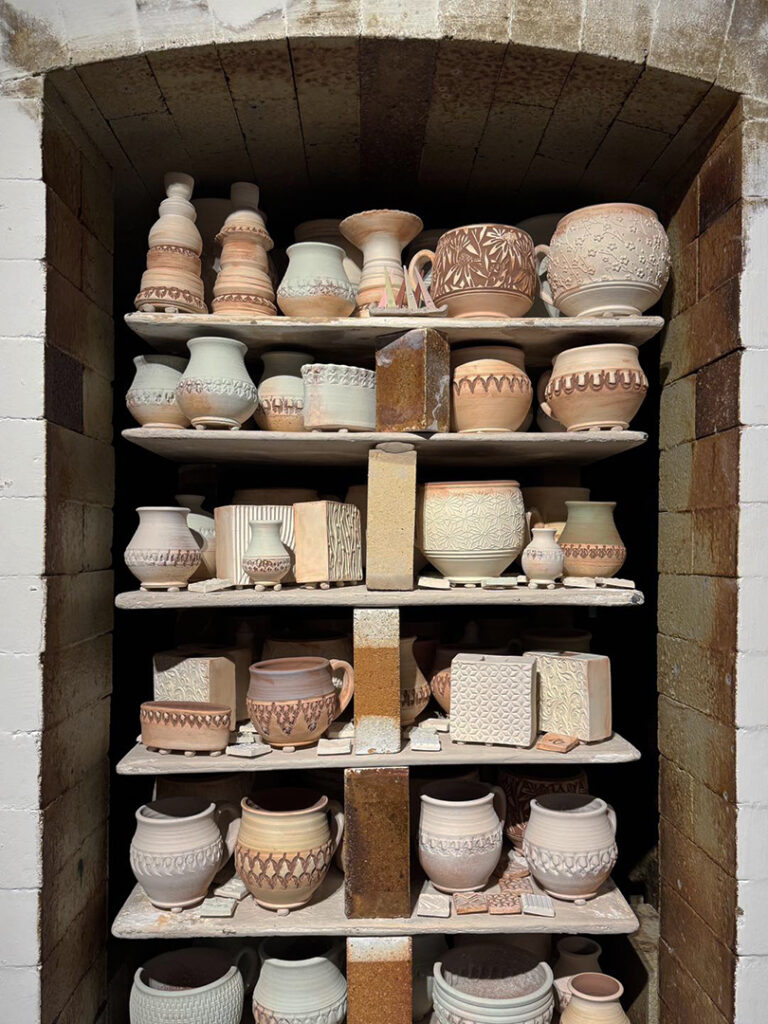

After a couple hours of loading the kiln… shelf by shelf… brick by brick… pot by pot… I finally filled all three stacks to the top. I managed to pack in a LOT of pots. Trying my best to maximize the firing fee vs. pots being fired. Hoping for good soda “glaze” coverage & some nice flashing effects. Also hoping for an easy firing in the new kiln… without too many surprises along the way!!!