One last thing before they dry… I added a layer of colored flashing slip to my batch of hybrid mugs. At some point, these mugs will be soda-fired so they should change to shades of oranges & yellows during the atmospheric firing.

Gary Jackson: Fire When Ready Pottery

A Chicago potter’s somewhat slanted view of clay & play |

One last thing before they dry… I added a layer of colored flashing slip to my batch of hybrid mugs. At some point, these mugs will be soda-fired so they should change to shades of oranges & yellows during the atmospheric firing.

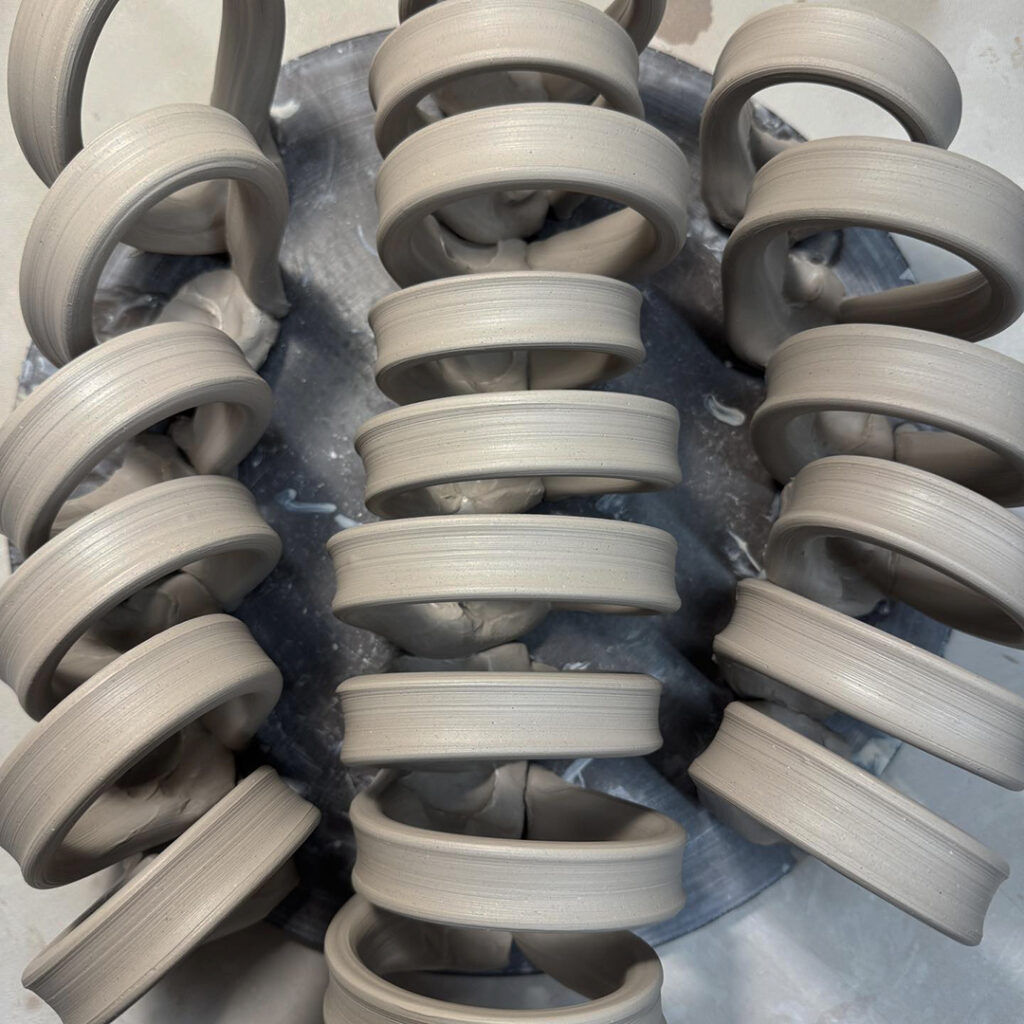

Handles pulled & resting… well, setting up & firming a bit before I start attaching them to make more mugs! I like to loop them over & stand them up so they can “stiffen” a bit with a good curve already established before attaching.

Getting ready to pull some handles again!!!

The more you do, the easier they get… just sayin’…

Accents painted & done! These mugs will be bisqued & then soda-fired. So they will not get any glaze on the exterior except for a little tenmoku in each stamped impression. The raw clay & colored flashing slips will transform in the kiln due to the firing process creating a nice “glazed” shine & flashing effects. Each one totally different based on where the flames hit it during the soda firing.

Just painting some details with colored flashing slips today. These areas will change colors in an upcoming soda firing kiln. These two should have accents of orange when this slip reacts to the soda atmosphere. Fingers crossed…

Handles attached… we now “officially” have mugs!!!

I’m a firm believer that by definition a “mug” needs a handle!

While some of my students might try to convince me otherwise… I’m not buyin’ it!!!

Another day pulling handles & making mugs!!!

My favorite thing to make… MUGS!

And for now they’re all going back under plastic so they can dry slightly to leatherhard clay. Then it’s trimming & adding of handles… and soon enough, these will become mugs!!!

My first 10×10 CHALLENGE of the New Year! And starting with my favorite thing to make… MUGS of course!!! More than ten thrown before 10:00am! Giddy-up!!!

First batch of packages on their way to their new forever homes!

More to come… seems like I’ll be at the post office a lot this week!!!

|

Gary Jackson: Fire When Ready Pottery

Lillstreet Studios ∙ 4401 North Ravenswood, Chicago, Illinois 60640 ∙ 773-307-8664 gary@firewhenreadypottery.com |