Mental note to self… don’t wipe the underside of a kiln shelf with your bare hand. You never know what the person before you in the kiln may have left behind!!!

Second note… buy more band-aids!

Gary Jackson: Fire When Ready Pottery

A Chicago potter’s somewhat slanted view of clay & play |

Mental note to self… don’t wipe the underside of a kiln shelf with your bare hand. You never know what the person before you in the kiln may have left behind!!!

Second note… buy more band-aids!

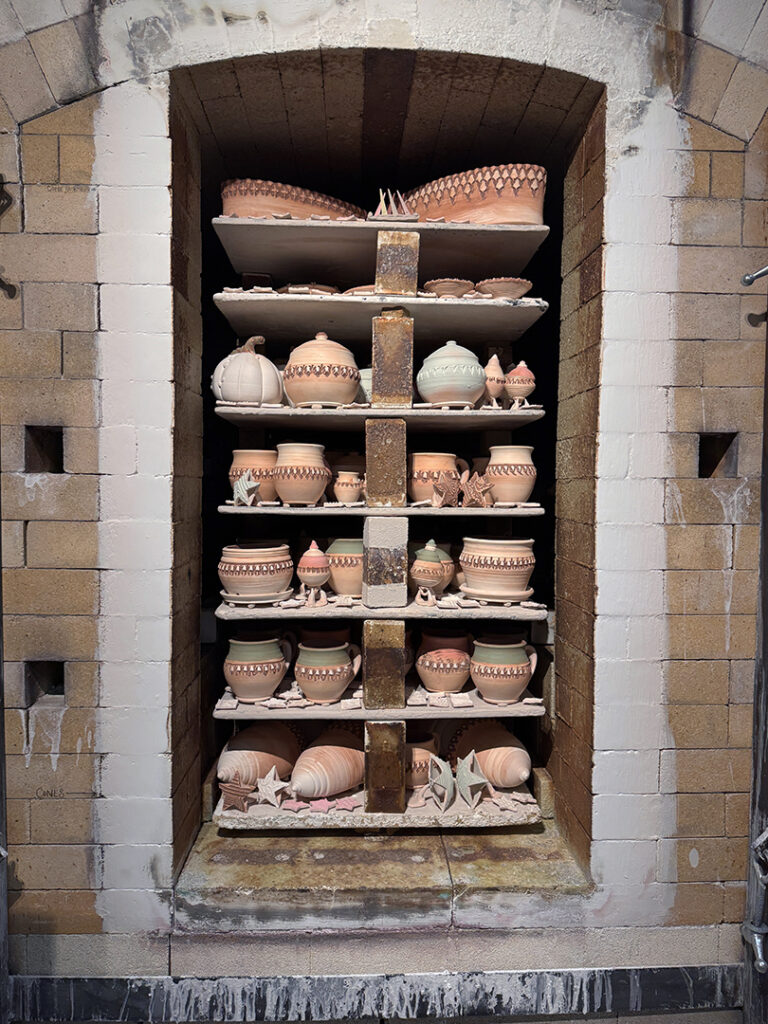

Just a quick sneak peek into the kiln to see the top layer of fresh, new Christmas Trees!!! Almost ready for this weekend’s HOLIDAY HOME SHOW. They just need a little more festive charm… coming soon!!!

You gotta love when a couple of your “studio friends” have a little extra space in their bisque kiln… and I just happened to have a few mugs ready to fill that space!!! Thank you Christine & Tracey… you da’ best!

A quick glimpse into my soda kiln… starting with a pretty perfect cone 10 !!!

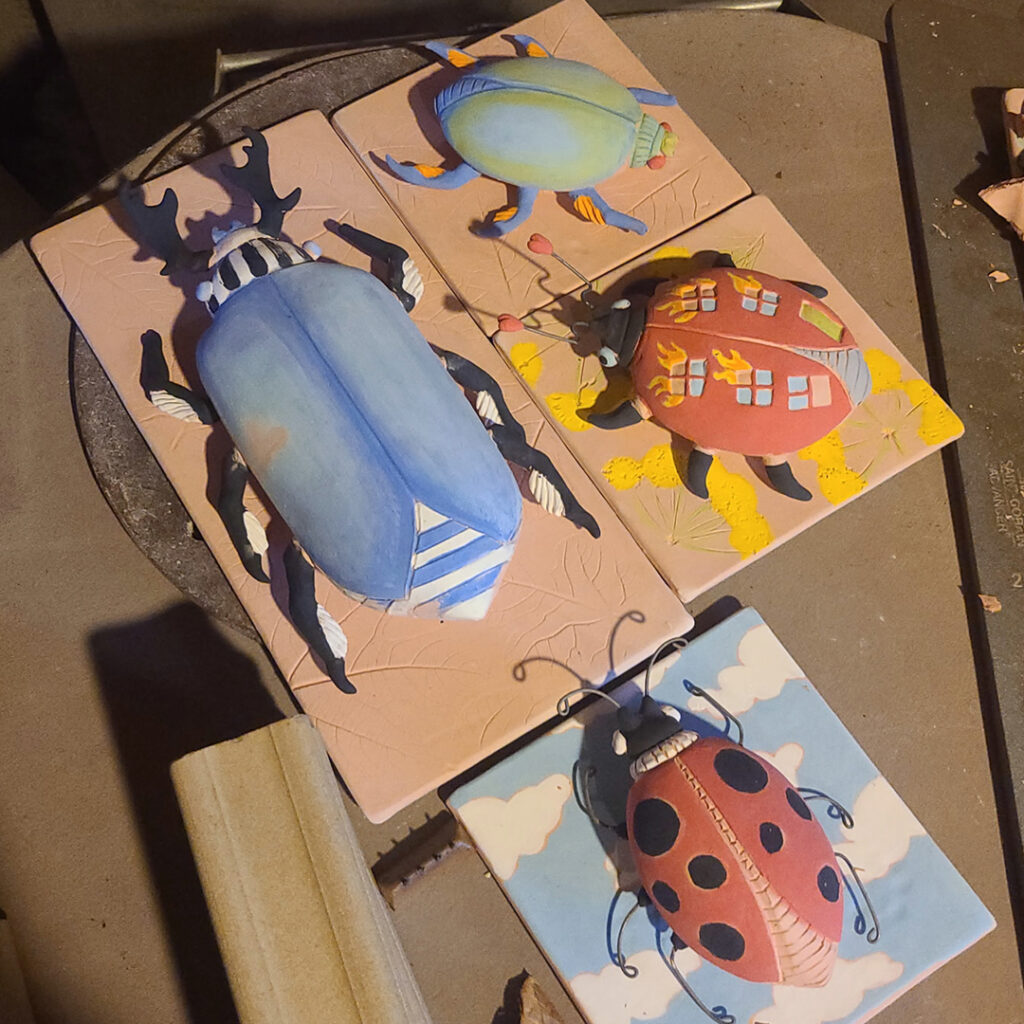

Looks like an exterminator found its way into Cory’s studio! All joking aside… sometimes bad things happen to good bugs. Pottery has this strange way of keep all of us very humble. Just when you start to think that you’ve got this thing under control, the kiln gods step up with a healthy slap of reality. We’ve all been there. It hurts. All that time & effort… gone. And it always seems to happen at the worst of times. So here we are… less than a week away from ART IN THE GARDEN.

But we artists are a resilient bunch. So Cory & I are quickly developing a “Plan B” and trying to make the best of a bad situation. Desperate times call for desperate measures… and a LOT more creativity!!! I’m sure she’ll make the best out of this… some are fine, some art salvageable, some aren’t. So we may be shifting gears… but we’ll STILL have some fun collaboration pieces to show off next weekend. Perhaps not so many bugs… but who knows, maybe some TV’s or other fun things???

A little morning glow in the kiln… just waiting for the cones to start falling!

So it took my just about three hours to fully load the soda kiln… kinda like Pottery Tetris! Trying to fit in as much as possible, all the while trying to leave some space for air to flow through during the firing. The soda atmosphere needs to get in between everything to leave its glazed finish. I piled a LOT of work into this one! The back stack is a single shelf filled first to the top. Then front stack is a double-shelf filled up to the arch. It’s packed tight… so it might be a long firing today?!

And then I rolled down my studio cart… the same one my Dad built for me several years ago! I have figured out that a full cart of glazed & wadded work pretty much equals a fully loaded soda kiln. The masking tape just works as a little “protection” so nothing jumps off the shelves while I take the rickety freight elevator downstairs… kinda like a pottery seat belt!!

Last night started with an empty soda kiln… full of possibilities.

|

Gary Jackson: Fire When Ready Pottery

Lillstreet Studios ∙ 4401 North Ravenswood, Chicago, Illinois 60640 ∙ 773-307-8664 gary@firewhenreadypottery.com |