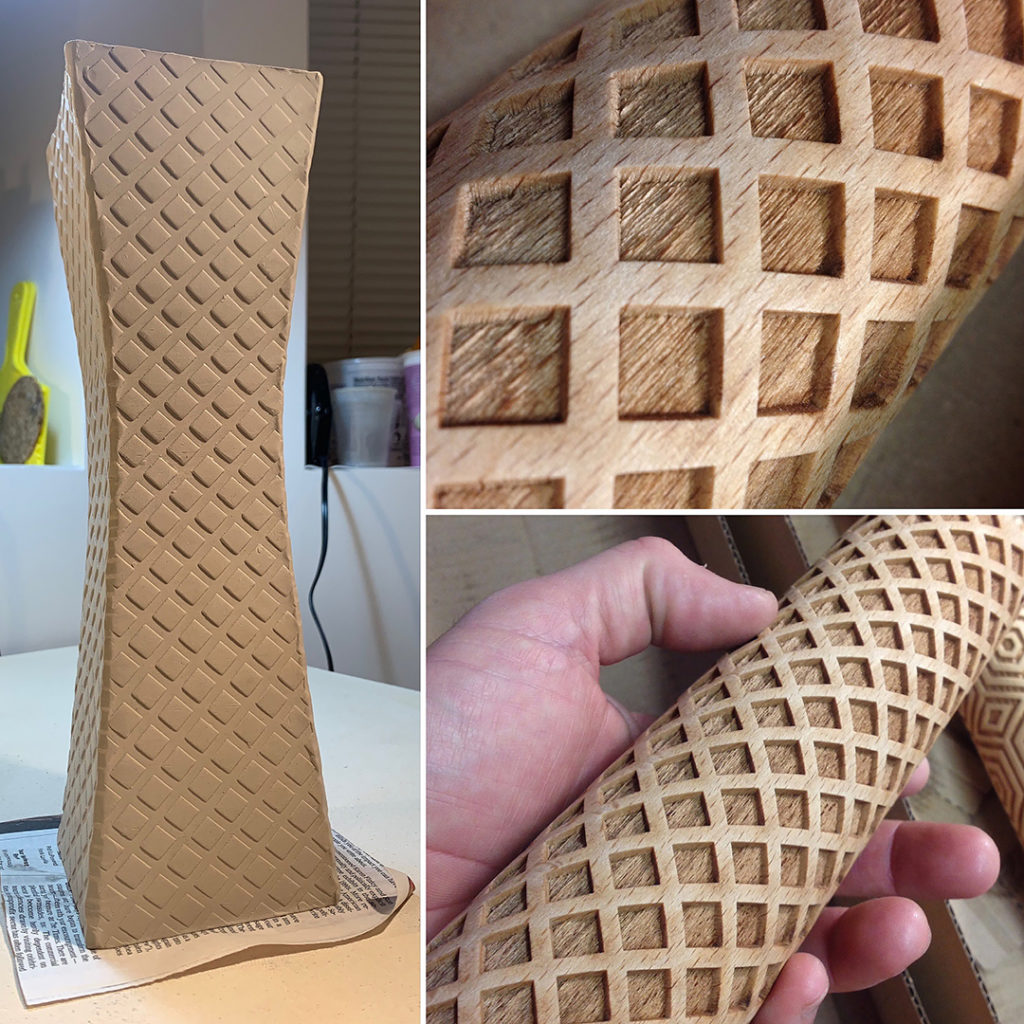

This week in my Beginning Wheel class we played with colored clay for “marbled” pots! I started by coloring some clay ahead of time for them with mason stains layered & wedged into B-Clay. We then layered regular B-Clay and/or Brown Stoneware with the colored clays… and then gave it two simple wedges to start the marbling. So much fun to see the colors presenting themselves as you’re throwing. When we were done, the pieces still have a “smudgy” layer of mixed clays like a dirty skin on the pot. When they get to leatherhard, we will carefully trim the entire surface off to reveal the clean lines of layered & marbled clays.

And yes, if we were doing more than one or two pots, I would have definitely used rubber gloves. But since this was a “quickie” demo and not a long-term pottery career of marbled clay… I figured it was tough enough for my students to throw their own forms, let alone to do it with gloves on!