Last night in my Beginner & Advanced Beginner Wheelthrowing Class, I showed my students how to throw basic bowls on purpose, instead of a cylinder gone bad. To start by creating the bottom curve of the bowl right from the start. To compress the curve. To avoid that little “stair-step gouge” that happens to a lot of beginner’s bowls.

After I had done the first bowl demo and answered questions, my students then moved on to work on their wheels while I threw eleven more bowls. It was basically a full bag of clay, cut into 12 balls of clay… to become twelve bowls!!! After I finished throwing them all, the class joined me again for Part Two of the demo. My favorite part – where I show them some quick “tricks” to alter & change each bowl so none of them look the same. It’s a fun demo, with the addition of colored slip for some added surface decoration.

Bowl #1 – Two simple finger twists on opposite edges.

Bowl #2 – And if two twists are good, then eight twists might be better?

Bowl #3 – A simple flange flared out with a little groove line to delineate inside from outside.

Bowl #4 – And if a thin flange is good, a wider one might be even better?!

Bowl #5 – A split rim… pinched in places and then squared off a bit.

Bowl #6 – A split rim pinched in places… then curved in & curved out.

Bowl #7 – A quick slip demo… showing a simple “covering” of white slip to make a two-tone bowl.

Bowl #8 – Some white slip on the flange… waiting to be carved through later.

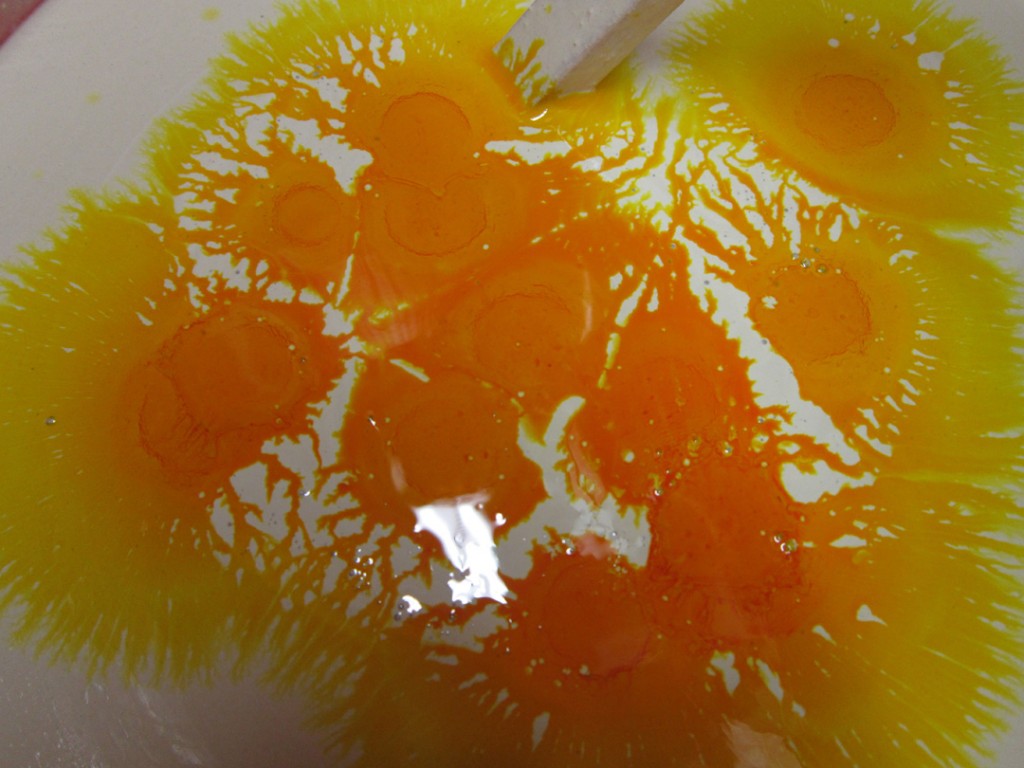

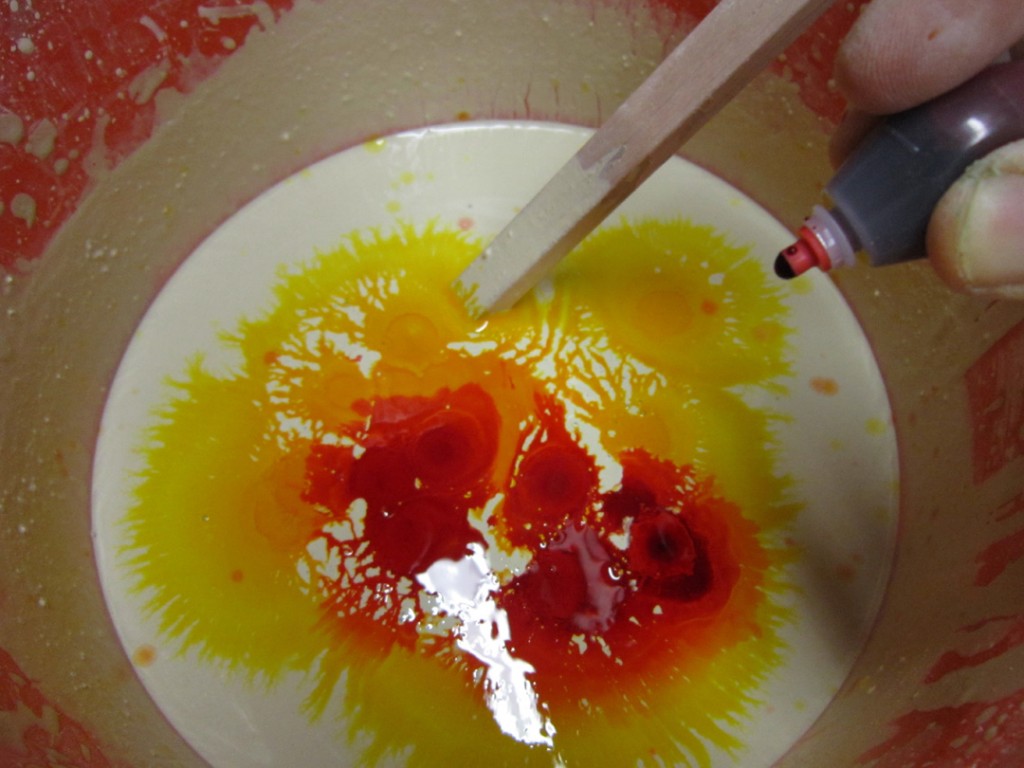

Bowl #9 – More white slip to cover the inside, then a simple swirl dragged through using the rounded end of my wood knife tool.

Bowl #10 – More slip… and a spiral, and some banding, and some squiggling!

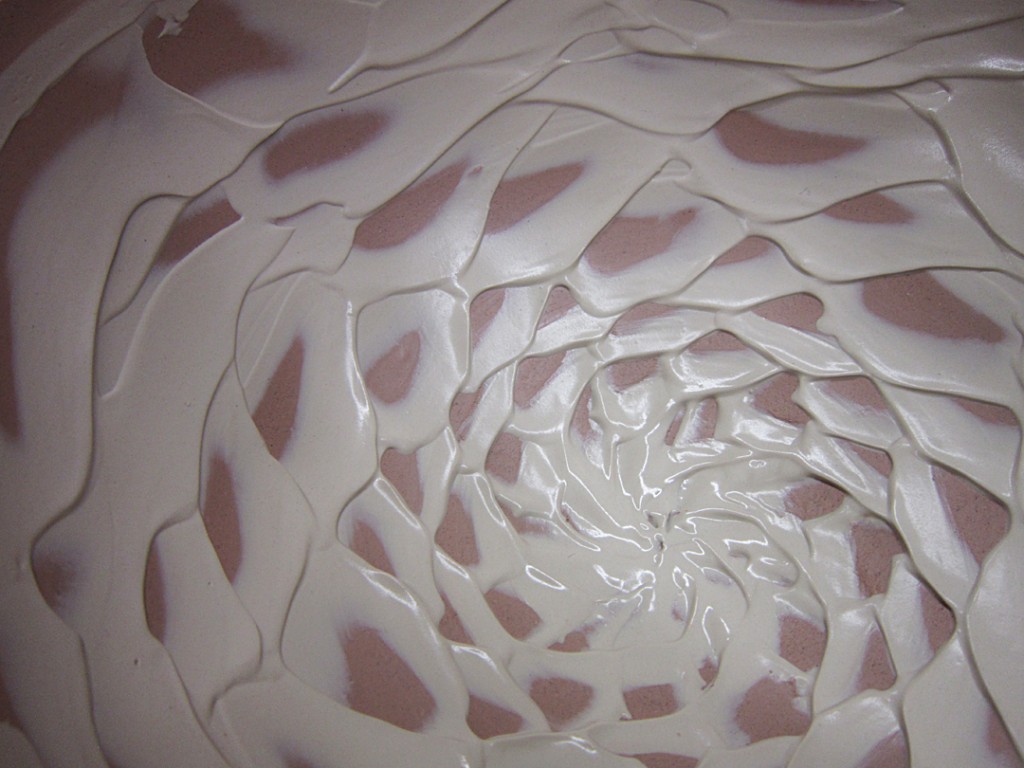

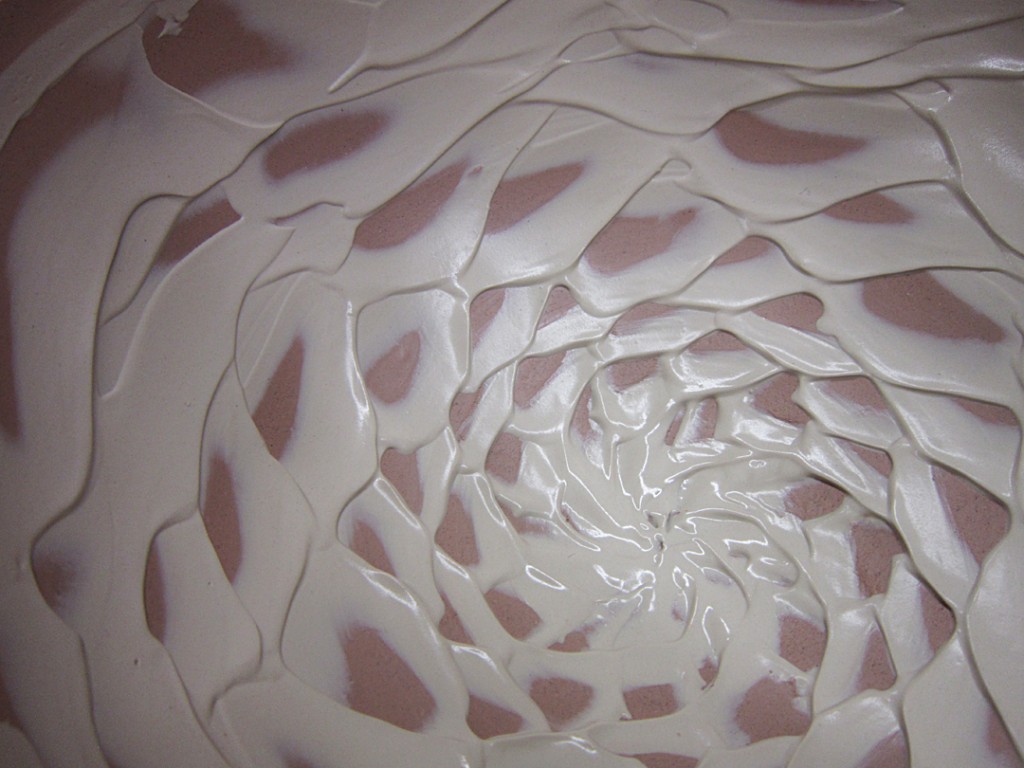

Bowl #11 – More white slip… this time using my green plastic rib to do some chattering through the slip as it is spinning.

Bowl #12 – And if one slip is good, maybe two blended together would give us a nice ombre effect… but then I couldn’t resist another spiral-swirl through the slip!!!

So all twelve of the bowls are now under wraps in my studio.

When they stiffen up a bit, I’ll do some more decorating & refining. Some stamping. Some carving. So more shape altering. And then of course, trimming of a good foot!!! Twelve different bowls… that all started out as a simple round bowl.