It was a long wait today… as the kiln temperature dropped ever so slowly.

I kept opening it slowly to “encourage” the cooling process; being careful

not to open it too quickly. When it got to about 250 degrees, I felt it was okay

to unbrick the door. And then it was time to start unloading the kiln.

Like a little kid on Christmas…

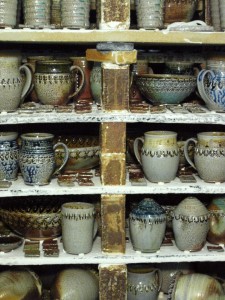

It’s always fun to unload the kiln – to see the results of your hard work. And to see how

things have been transformed during the atmospheric firing process. It was a very

tightly packed kiln. I was concerned that there may be some “dry patches” in the kiln

because it was packed too tight… luckily the soda made its way through the kiln and hit

everything quite nicely… if I do say so myself. Only two mugs were on the “drier” side.

All in all, it was a great firing with great results.

But then, after unloading and packing everything into boxes to get it home…

I still had to clean the kiln, scrape & kiln wash all the shelves, sweep out the fire box

and all of that fun stuff that comes with maintaining the kiln! Exhausting…

Today was firing day. A long day. But worthwhile when I get to open it in a couple days!

So I started early this morning by “pumping the flames” into the kiln. There are two burner

ports on the back of the soda kiln, one on each side of the chimney. It starts up slowly,

with gradual increases in gas & air to ramp it up for the first couple hours.

About a half-hour into it, I came down for the first turn-up, checked the kiln,

checked the flames, checked the reduction, checked the cone packs… only to be

surprised to find that the bottom cone pack was gone!!! Missing. No signs.

My guess is it must have exploded or fallen off the shards that held it in place.

Luckily, I rely on the top cone pack a lot more than the bottom.

During the firing, you’re “trapped” at the studio… can’t leave, can’t really start much

as you need to check the kiln throughout the day. So it’s a lot of finishing little projects,

cleaning, sweeping, dusting, trimming class demo’s, chatting and waiting for the kiln.

When the kiln finally begins to reach the top temperatures, it’s time to mix up the

soda mixture that will be introduced into the kiln. Who knew that such a “sloppy mess”

of soda ash, soda bicarbonate, whiting, wood chips & water could make your pots

look so great?! It looks like an odd mix of oatmeal & tuna?!

When the kiln is around cone 9, I start introducing the soda mixture into the kiln

on an angle iron. Dropping soda mixture into the kiln every 15-ish minutes until the mixture

is gone. Tonight I also had two assistants putting the soda in. Two of my beginning wheel

students were there working and had never really seen a kiln firing before. So I offered

to show it to them, and even let them put some of the soda in. Pam was surprised

how hot it was back by the kiln, and Chuck had that instant look of “pyro-addiction.”

He loved putting the soda in… the flames, the heat, the danger… he’s in!

And I loved having the help. After the soda is introduced, the flames come shooting out

of the peeps as the atmosphere inside the kiln is quite volatile – with the evaporated soda

mixtures flying all around the kiln and hitting the pots inside!

After all of the soda is in, I let the kiln continue longer so the soda can “soak” and spread

a little more as it gets to it’s top temperature and cone 10 finally drops! During that

soaking time, I had a chance to hang out with Chuck & Pam… and had to laugh at the

persistence, dedication & focused attention Chuck had as he was applying slip to one of

his pots! Not bad for one of my “tile-class-convert” wheelthrowing beginners, huh!!!

After a good soaking, it’s time to turn the kiln off… and it’s suddenly silent.

Turn off the gas. Turn off the blowers. Turn off the exhaust fans. Close the damper

and call it a night. Now it’s time to wait again… as a watched kiln never cools!

So tonight I finally loaded the soda kiln. After months of making work, bisquing,

glazing, wadding and more… tonight was my night to load the kiln. Tomorrow I’ll be

firing the kiln all day. But first… here’s my step-by-step loading process from tonight!

The kiln was empty and waiting for me. You always start with the back stack. I load

the entire back stack, one shelf deep, all the way to the top… then move to the front

two shelves and load them all the way to the top. Each shelf is placed on kiln posts

of different heights to make the shelves work with the heights of your pots. With lots

of tiles conveniently fitting in between all of the pots – the perfect kiln filler!

Lots of pots. Lots of tiles. All different sizes. All different shapes. It’s sort of a 3-D puzzle…

loading in pieces, trying to get as many pieces in as possible – while making sure there’s

enough air space around everything for good soda flow & coverage. It’s tough…

the more I “squeeze” in, the more I feel like I’m getting my money’s worth for the cost

of the kiln firing! Pack it too tight, and some of the work may not be covered & glazed

with soda. So I keep packing… up to the top!

Then it’s time to move to the front two shelves – and load them both at the same time,

layer by layer. Again, matching the brick heights with the work going in. Part way up…

another Kodak Moment.

More pots. More shelves. More posts. Layer by layer. And a LOT of tiles!!!

But then it’s done. Loaded all the way to the top. With one last shelf carefully slid in

at the top… just a few more tiles and a couple cups. Whew… a lot of stacking,

a lot of posts & heavy shelves! And I’m sweating… but glad it’s done.

Once the kiln is packed, and the cone packs in place, the door then needs

to be bricked closed. One brick at a time. Alternating, some this way, some that way.

Making sure that the peeps are in, and line up with the cone packs so I’ll be able to see

them during the firing. Yes, the peeps are the “brighter white” bricks that can be

pulled out for a quick peek.

And then it’s done for the night. Put to bed. Trying to get a good night’s sleep

for tomorrow’s long day of firing! And… scene!

After the mini’s… I did a LOT of glazing! A lot of liner glazes. A lot of inlaid glazes.

A lot of wadding. With a bit of colored glazes sprayed on for accents here & there.

My studio cart filled up quickly… ready to be rolled downstairs to the kiln.

Well, not quite yet. Before I left tonight I rolled the cart and turned it around…

so now the entire other side of the cart can be filled with glazed pieces!!!

As mentioned, my rolling cart will travel downstairs for the kiln loading.

With a rickety freight elevator as my only means of transportation, I have found

that some masking tape “safety belts” tend to keep my pots safe… as they jiggle

and bounce around on the trip downstairs!

I will be loading my soda kiln next Friday, and then firing on Saturday.

And I still have quite the pile of bisque stacked up waiting to be glazed!

Tonight I started glazing. After a LOT of rearranging… a LOT of stacking…

just trying to make some space to organize my bisque & make room to work.

But I finally got my act together and started inlaying glaze into my stamped textures.

It’s kind of a lengthy process where I fill the stamps with glaze, let it dry

and then wipe off the top surface with a damp sponge to clean off the pot surface,

but leave glaze in the stamped recesses. Since these pots will be soda-fired, the pot

surface will remain unglazed – leaving the soda atmosphere to do its magic! The glaze

inlays will help accentuate the stamping, and the colored slip will give it color accents.

Tomorrow the glazing process will continue with liner glazes, wadding and a bit of

sprayed glazes for a little extra splash of color on a few of the pieces. Then continue

the same process all over again with the bowls… flower pots… vases… and more!

A lot of pots to glaze & wad before I can load & fire the kiln!

Another loaded bisque kiln… layer by layer… piece by piece… firing today!!!

Love the challenge of stacking, nesting and piling in of as much work as you can fit in.

Guess I’m going to need to do some glazing – and get a soda kiln scheduled soon!

Layer One – flower pots, mugs and tiles!

Layer Two – bowls, flower pots, tumblers and more tiles.

Layer Three -bowls, mugs and a LOT more tiles!!!

Layer Four – bowls, flower pots, tumblers and tiles!

So while my bisque kiln cools tomorrow…

I’m taking a day off and heading out of town for a little hiking in the woods!