Rushing to get some Halloween fun made in time for “Art In The Barn”…

it was time to crank out some pumpkins. And once I had made pumpkins, it was time

to turn them into Jack O’Lanterns! But I digress, let’s go back to the beginnning…

I started by throwing some terra cotta orbs… simple enclosed forms with air trapped inside.

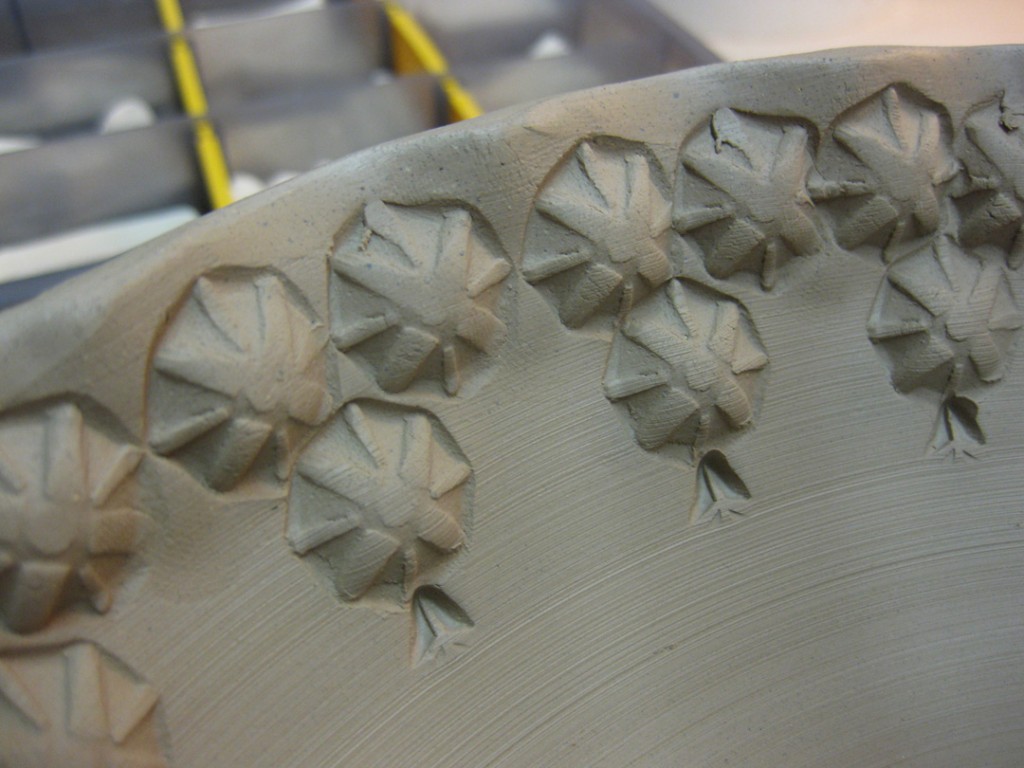

Once they had dried a bit overnight, to a wet leatherhard, I gave them some textured

pumpkin “stripes” and altered their shape using the edge of a square chopstick.

And we all know that a good pumpkin needs a good stem.

Doesn’t everyone look for a groovy, cool stem on their store-bought pumpkin?!

So I rolled a coil, gave it some texture lines, attached it with some good scoring & slipping,

then twisted it and animated it a bit.

Now that I had pumpkins… it was time to carve faces into them like a good Jack O’Lantern.

First, I carved out the eyes, nose, mouth and details. Then I opened the pumpkin and “cut off”

the top with a good angle so that the lid fits & doesn’t swivel around. I added some “warts”

for added texture & whimsy… as well as two on the edge of each lid to help people line them

up to close the pumpkins properly.

I let them all dry overnight and then came back to paint them with colored underglazes.

I did some sponge-painting with the orange underglaze so that some of the terra cotta color

would show through and give them some depth – not just flat, solid orange. And a bit of green

on the stems to help accentuate the stem texture. I dried them overnight on plastic grid

sheets with fans oscillating overnight.

Then, after teaching my class Tuesday night, I glazed the Jack O’Lanterns with low-fire clear

glaze. I actually sprayed on the glaze to get a nice even, thin coat. Luckily, this crazy green

color disappears during the firing… and the colored underglazes will pop after firing!

Tonight the kiln was cool enough to unload… and I was pleased to see the shelf-full

of Jack O’Lanterns smiling back at me. Each one funnier than the next.