Ready to get some trimming done tonight. This batch of porcelain mugs are coming together… and giving me something a little more “normal“ to focus on!

Gary Jackson: Fire When Ready Pottery

A Chicago potter’s somewhat slanted view of clay & play |

Ready to get some trimming done tonight. This batch of porcelain mugs are coming together… and giving me something a little more “normal“ to focus on!

Tonight I got to do a little stamping here & there… and there… and there… just a few more porcelain cylinders working their towards becoming more mugs!!!

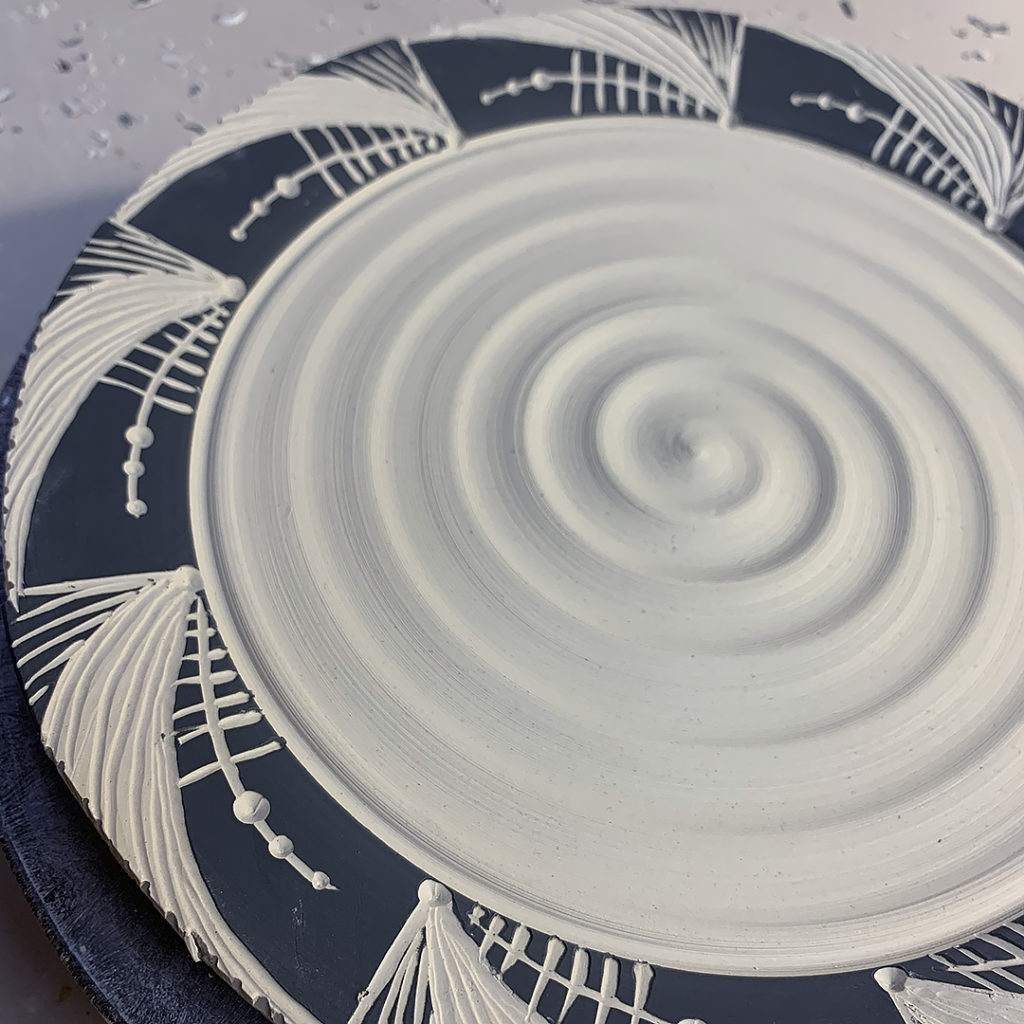

My original plan was to have these sgraffito platters ready for my first art fair in April. Well, that’s been cancelled… but I’m still trying to stay on top of things. So here’s some of my latest sgraffito fun in the studio. Working on a few platters using my favorite DiamondCore carving tools!

Platter #1

Platter #2

Platter #3

Platter #4

Platter #5

Painting black slip on white porcelain… kinda antithetical,

but setting up a good “canvas†for a little sgraffito carving!

So it’s never quite as easy as you would think.. it takes several layers and several paintbrushes full of black slip before you start to get a nice even banded layer. But with a bit of paintbrush perseverance…. I finally got them done, back under plastic waiting for them to set-up a bit more… and then some day soon I’ll start carving some sgraffito patterns into the black banded areas!

Scratch, attach, repeat… repeat… repeat…

It’s been a very productive day playing with porcelain making more of my favorites!

Porcelain handles pulled… just setting up a bit before I start attaching. I like to sit them up in an arched curve as they stiffen up – so that the majority of the bending is already done so there’s less cracking if they dry out a bit too much.

Another night… another two dozen mugs!!!

Happy Mugshot Monday… making my favorites!!!

Now just for a little clean-up & colored slip accents tomorrow.

Score… slip… attach… repeat… repeat… repeat…

Just setting up for an early morning trimming session.

Always better when you ave some great tools to work with… like my Bison Trimming Tools!

Last night I finished off the latest batch of mugs with some final accents & detailing with colored flashing slips. So now they’re drying before they go into a bisque kiln… and then glazed… and then into the soda kiln where these flashing slips will change colors as they get hit with the flames & the soda atmosphere!

|

Gary Jackson: Fire When Ready Pottery

Lillstreet Studios ∙ 4401 North Ravenswood, Chicago, Illinois 60640 ∙ 773-307-8664 gary@firewhenreadypottery.com |