It’s been a productive afternoon… and now I’m adding pulled handles to the hybrid mugs. Score, slip, attach, repeat… repeat… repeat…

Gary Jackson: Fire When Ready Pottery

A Chicago potter’s somewhat slanted view of clay & play |

It’s been a productive afternoon… and now I’m adding pulled handles to the hybrid mugs. Score, slip, attach, repeat… repeat… repeat…

It was a very productive evening in the studio. Lots of stamping, trimming & finishing. I had a lot of oval vases, class demo bowls & summer camp demos to attend to. Luckily, I got them all done… and now they’re drying!

Finishing up a batch of large oval vases. Just adding some accents of colored flashing slip in the stamped textures. The colors will show up better after soda-firing… this slip should turn orange!!!

Textured slabs attached… another batch of hybrid mugs well under way. Next up… trimming & handles. Thanks again to my assortment of handrollers from MKM Pottery Tools for the fun textures & patterns!

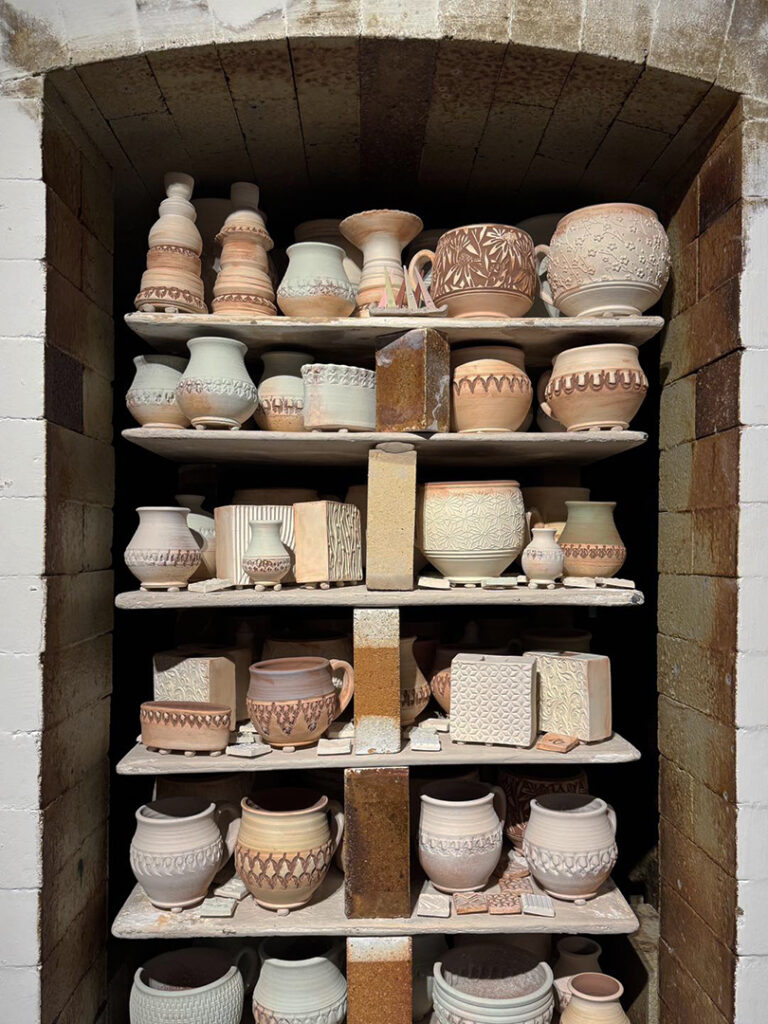

After a couple hours of loading the kiln… shelf by shelf… brick by brick… pot by pot… I finally filled all three stacks to the top. I managed to pack in a LOT of pots. Trying my best to maximize the firing fee vs. pots being fired. Hoping for good soda “glaze” coverage & some nice flashing effects. Also hoping for an easy firing in the new kiln… without too many surprises along the way!!!

A little early morning trimming! I’m trying to speed-up the drying process a bit. So they’re drying upside-down on elevated plastic grids. Better air circulation on all sides this way.

Assembled… now with handles! This latest batch of hybrid mugs finally all have handles… thus making them MUGS!!! I’m a firm believer that a “mug” by this potter’s definition must have a handle!!! So they’re all attached & ready to “relax” a little under some plastic overnight… before I come back to touch them up a bit more before drying.

Here they are… a bunch of handles pulled and almost ready to go! I like to loop them over like this so they can set-up for awhile before attaching. I want them to be soft & malleable… but not sticky & squishy. Plus, the loop sets-up most of the handle’s curve for later when it goes onto the mug!

It’s been fun using some of my new handrollers today from MKM Pottery Tools. I’m generally a more “geometric” kinda guy when it comes to patterns & textures. But I will say I’m pretty excited about some of these new rollers that a more “illustrative” pattern on them. We’ll see how it goes with more rollers for more patterns!!!

ugh.

You know it’s my least favorite thing to do… but at some point, a little glazing has got to happen.

But first… I get to apply wax to all of the bottoms to make my glaze clean-up easier later.

I do enjoy waxing bottoms… glazing not so much.

|

Gary Jackson: Fire When Ready Pottery

Lillstreet Studios ∙ 4401 North Ravenswood, Chicago, Illinois 60640 ∙ 773-307-8664 gary@firewhenreadypottery.com |