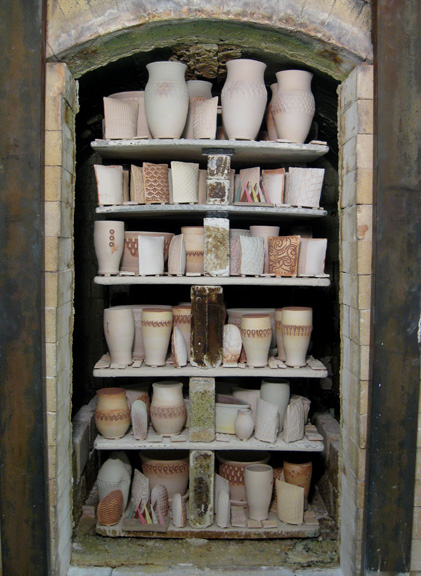

The firing day starts off early – trying to get a good jump on what is inevitably

going to be a LONG day! So the kiln is turned on with fingers crossed.

Throughout the day, certain adjustments are made to the gas lever, the air level

and the damper. As the temperature rises, you can watch the pyrometric cones

drop during the day.

All was going well today… I was getting alot of “busy” work done while firing.

I cleaned my much-needed studio. I glazed some class demos. I wadded more tiles.

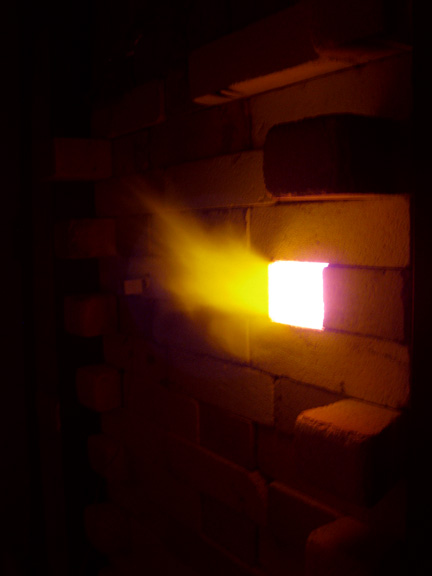

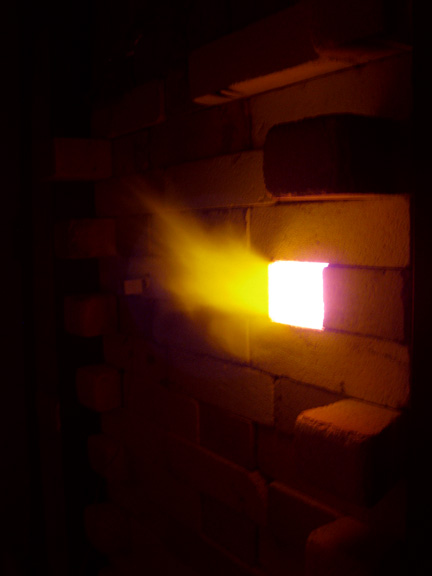

As the kiln gets hotter, and it is placed into reduction, you can see the kiln glowing

and flames shooting out – look what happens when you pull out the peep brick!

The kiln firing was going great… practically firing itself…

Until it was time to introduce the soda mixture to the kiln.

When the kiln is getting up towards the top temperatures, around cone 9, I start

to add a moistened mixture of soda ash, soda bicarbonate, whiting & wood chips.

For some reason, when the first batch was added, the flames of the kiln blew out.

Luckily, the kiln is designed to re-light itself if that happens. The second batch

did the same thing?! Not sure why… but luckily, it re-ignited and all was well.

It wasn’t until the third time that it blew out – and DIDN’T re-light itself?! Uh oh…

So after some quick problem-solving, and some input from others, we got it going

again after losing about 20 minutes and over a 150 degrees! Unfortunately…

that problem just added a few more hours onto my already-long firing time!

Upon further inspection, it appeared as though the thermal coupler sensors

in one of the burners was not in far enough – and therefore not “holding the heat”

well enough to keep the flames going?! So I bent down the pipe that holds the

thermal couple in the flame – and propped it up with a kiln post!

And all seemed fine after that... back to the firing!!!