After a few long days of glazing & wadding, I was finally ready to load the kiln.

An empty kiln has such potential…

I always start in the back with a single stack of shelves. These will get hit with a bit less soda than the front, so I plan ahead and use different clay bodies for this area. Porcelain & B-Clay “blush” really well back here without getting “blasted” by the soda. As well as pieces that have a git more glaze, or I’m hoping for a more subtle effect.

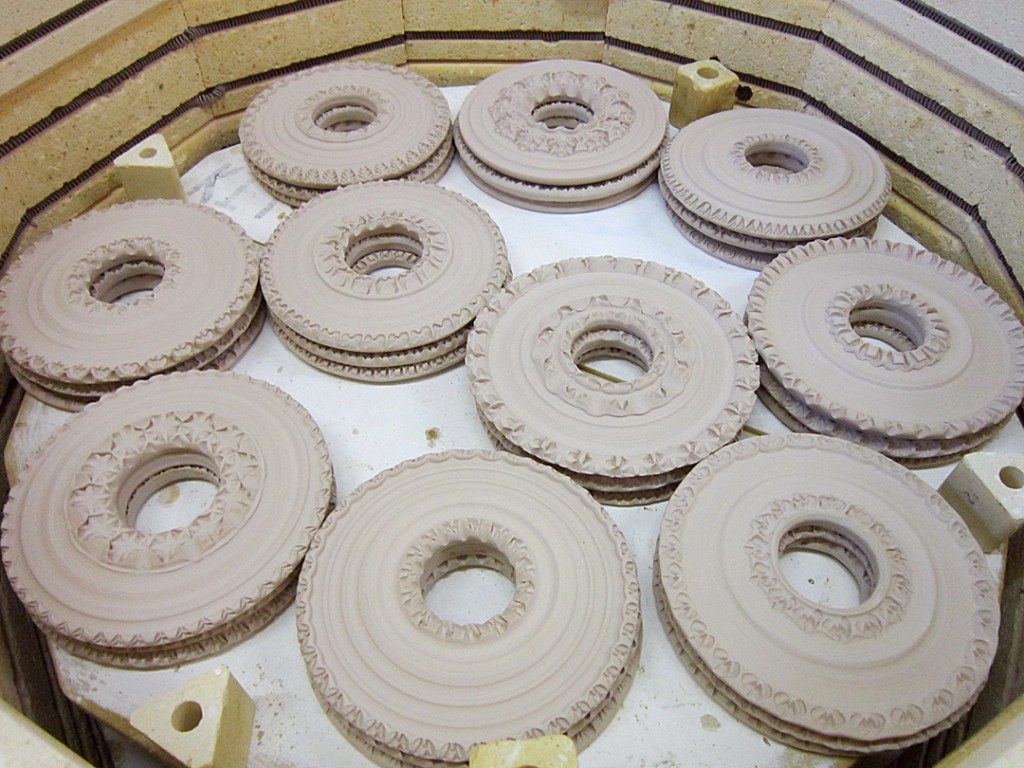

The middle & front stack of shelves get built at the same time. It’s always a puzzle putting it together. Trying to fit in as much as you can while leaving a bit of airspace for the soda to travel through. As you’ve seen… I LOVE to pack a kiln. And I LOVE kiln filler. So it all comes together in this final glaze firing… as I pack it tight and try my best to cover every possible space of kiln shelf!!!

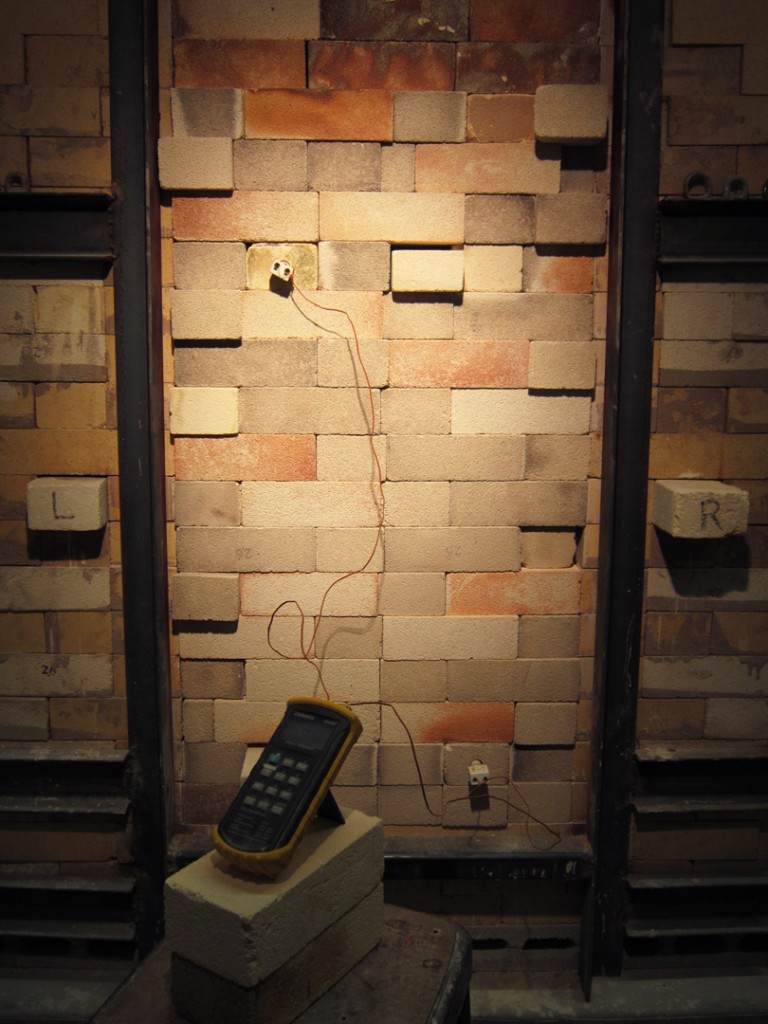

Once loaded and the cone packs are in place, it’s time to start bricking it up… one brick at a time!

All closed up. A very short preheat while I tidy up & gather my things.

And then it’s off for the night – waiting for an early start tomorrow morning.