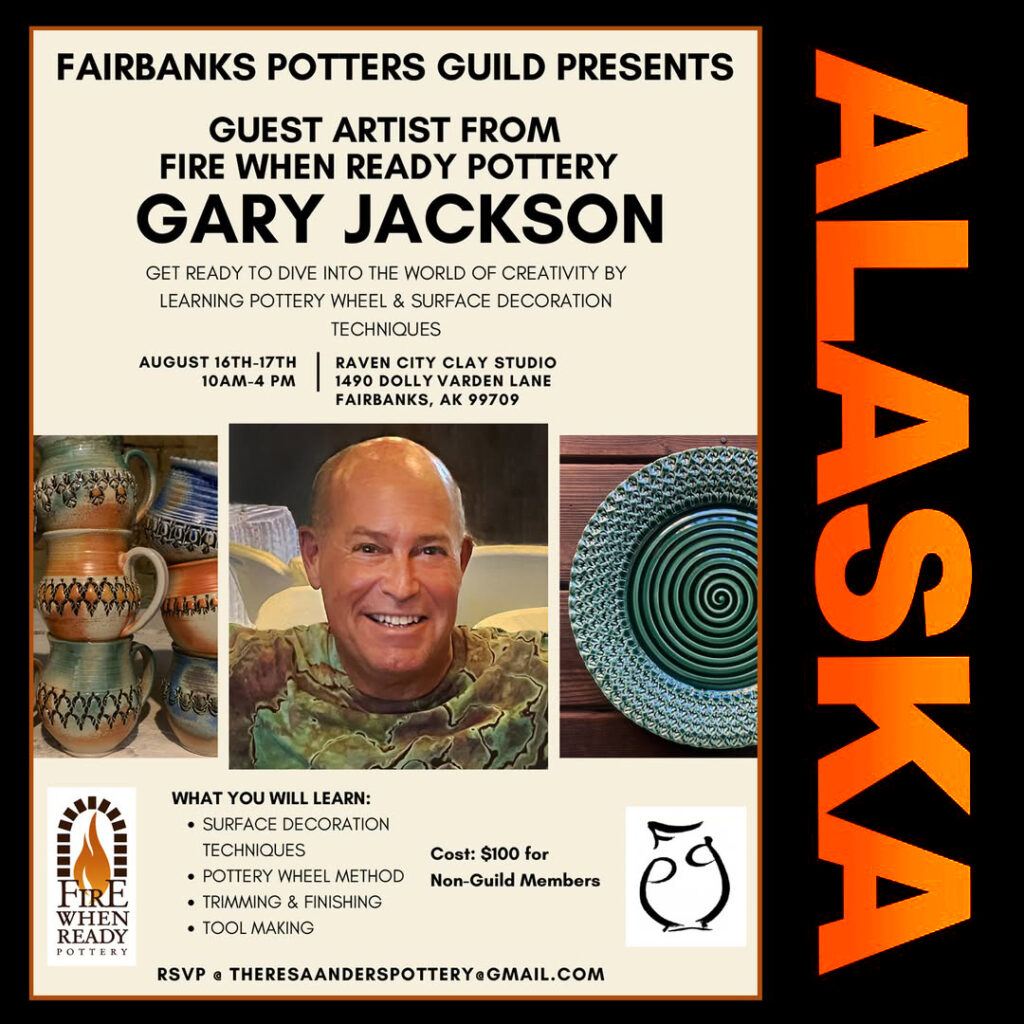

I had an amazing adventure up north in Alaska this past week. And I “might” have taken “just a few” photos along the way! I’ve got a LOT of editing to do… and I promise a lot of posts with a lot of photos. But it might take awhile… as I’ve got to get back into pottery-mode! That soda kiln is not going to load itself by Friday!!! So… until I have a chance, here are a few “teaser” photos from my time in Alaska! Not to mention all of the pottery fun I had with the Fairbanks Potters Guild & my personal “tour guide” Theresa!!! Thank you Alaska!!!