Over the past year, I’ve gotten a lot of comments on this blog and Facebook asking for me

to show how I make my stamps. To me, it’s pretty simple. It’s a piece of clay. Some tools.

A little squishing & carving. Nothing too technical. In case you’re still feeling a little

apprehensive, here’s a photo tutorial of how I make my stamps. And thanks for asking.

I start by rolling some simple coils. Different sizes. Different widths. I try to keep them

clean, uniform and smooth. But that’s just me. I do roll a few of them out so they have some

time to stiffen up a bit before adding the designs.

Then I pull out a collection of tools. Anything I can use to press into the clay to make an

indentation. Nothing special. Just some random tools.

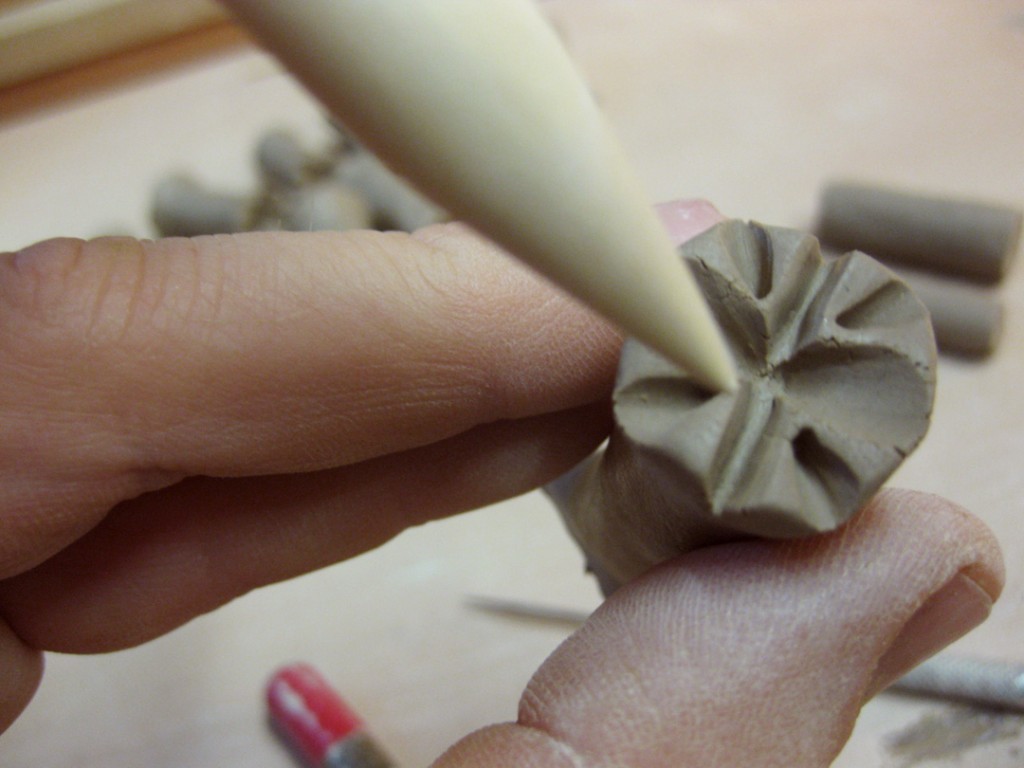

Then I start pressing the tools into the ends of the coils to make my stamps. I always put

a different design on each end of the coil. That way I get two stamps for one piece of clay!

What could be better?!

But before you start randomly pressing in patterns, there are a few things to remember…

1. Whatever pattern you press IN to your clay coil will be what sticks OUT where you press

it into your pot.

2. The impression left in your pot will appear to be the opposite of design on your stamp.

3. If you try to do letter stamps, they’ll need to look reversed on your stamp to turn out

correctly when you press them into your clay.

4. It’s not just the design, but also the perimeter shape that will make impressions.

5. You need to make sure your indentations & lines are wide enough & deep enough for clay

to be able to get in there. A lot of people try to “draw” with their needle tool, but then find

out later that they’re not getting a clean impression. That’s because they either left it all

scratchy from the needle tool… or more likely it’s too thin – no clay can get squished in there!

6. All of your stamps need to be dried and then bisque fired prior to pressing into clay.

7. I generally wait until my pots are on the slightly wet side of leatherhard for good stamping.

If your pot is too wet, the stamps will stick too much. If your pots are too dry, the stamp

won’t go in far enough to make a clear impression… or worse yet, crack the pot.

8. When pressing my stamps into the pot to create the design, I make sure that I have a finger

inside the pot opposite where I’m pressing the stamp. So that I have even pressure –

stamp pressing in, finger pressing out, squishing clay between the two.

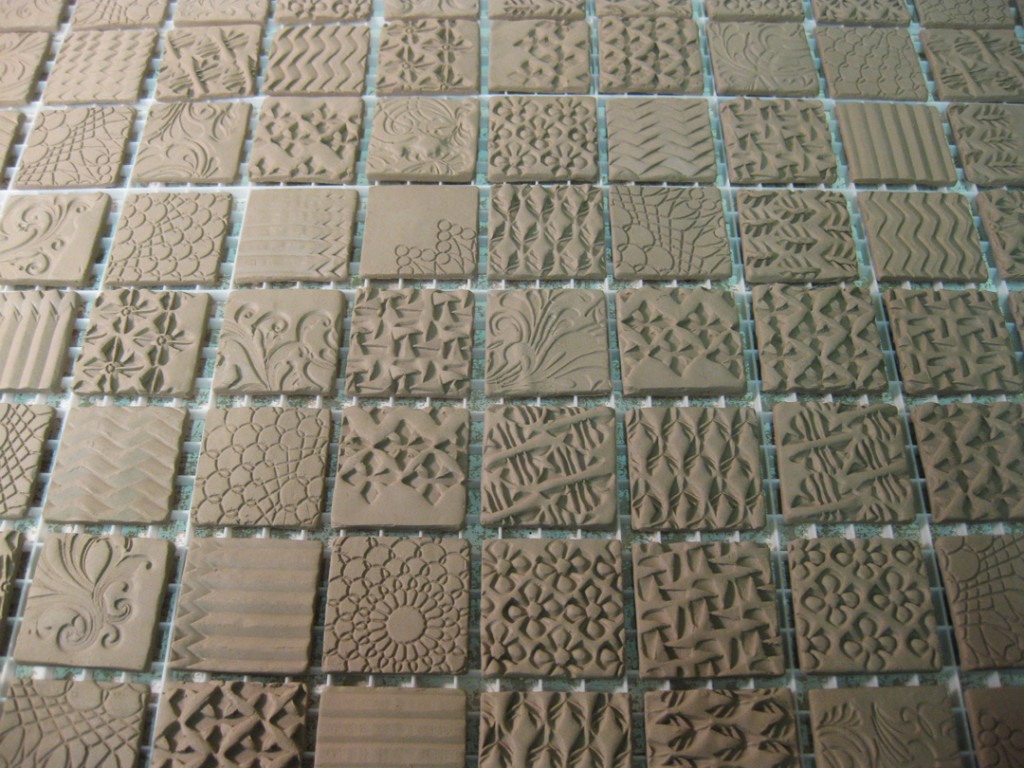

So here’s a few examples of a few new stamps. I won’t really know how they’re really going to

work until after they’re bisqued and I can actually use them for the first time.

After some time, I’ve made a few new stamps. Each one a little different. Of course,

when they come out of the kiln and I use them for the first time, there will be favorites….

and there will be some that aren’t quite what I was looking for. But that’s okay. You can always

make more. And just because they’re not making the mark you intended does not mean that it

is a bad stamp. Save it for awhile, try it a couple times, and you may grow to love it more later.

One last thing before I set them out to dry… I print my name on the side of each one.

Working in a group studio area and teaching classes, you never quite know where your

stamps may end up. I don’t think that I’ve ever really “lost” one, but it never hurts to label

your things just in case. So yes, every stamp gets labeled before they dry.

Once they’re dry, they will go into a bisque kiln firing. All of my stamps are fired once

so they are sturdy and porous. If they were fired to cone 10, they would become vitrified

and no longer porous – which also means they would stick to the clay. If your stamps stick,

they will not release from the clay cleanly and your impressions will not look as clean.

So there’s my quick photo tutorial of how I make my stamps.

My biggest suggestion is to make LOTS of stamps, and learn from every batch.

Learn how to make the stamp you want. Learn how to use your stamps on your pots

to get the stamped designs you want. Learn to make pots with stamps you love!!!