More snow means more shoveling… which also means more hot chocolate!!! Which is really just the “vehicle†to get more marshmallows into my mouth!!!

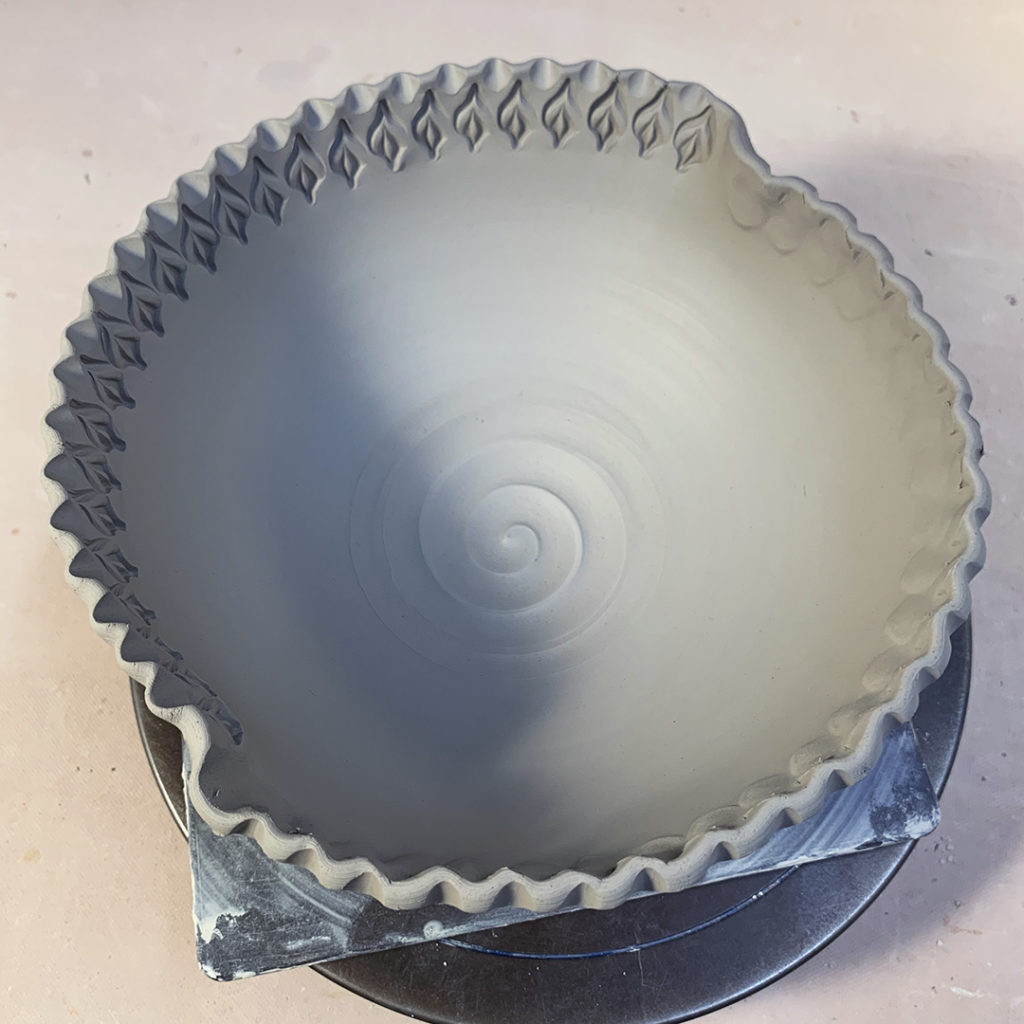

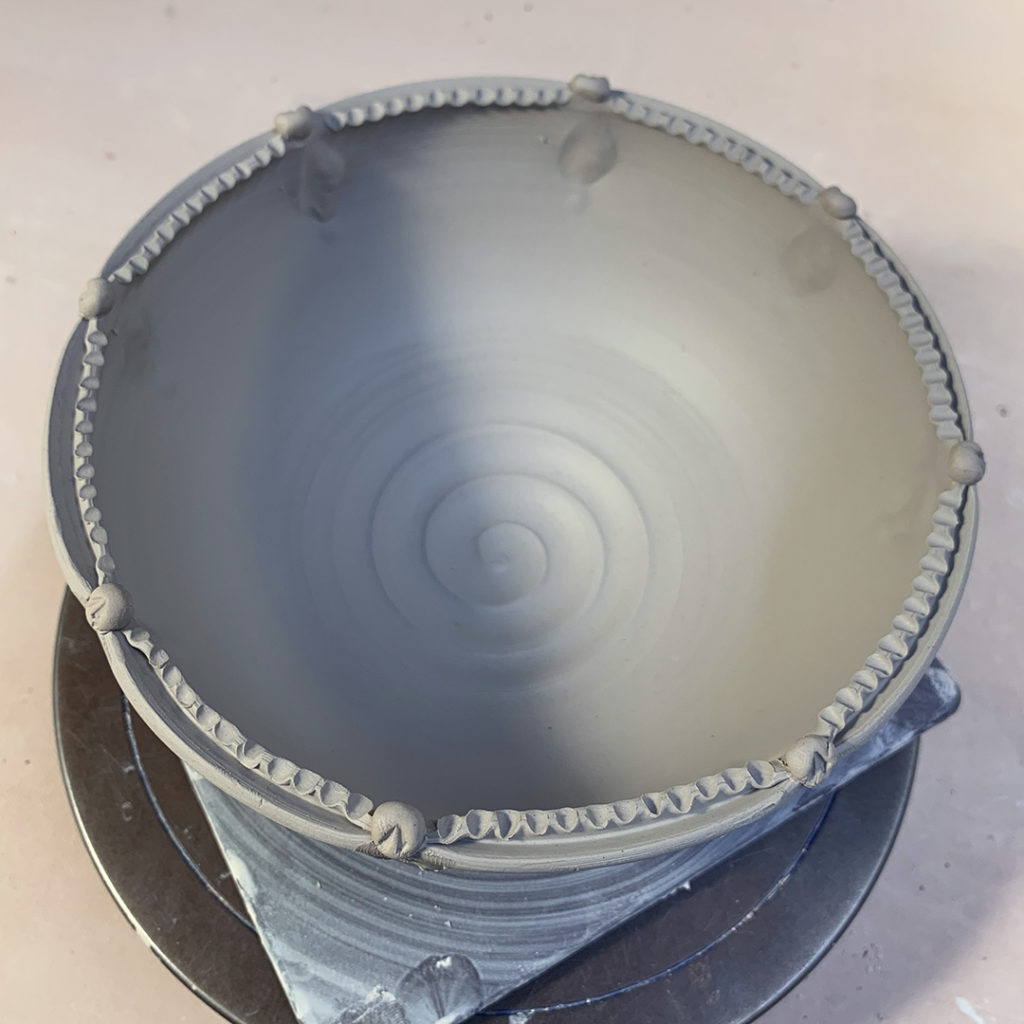

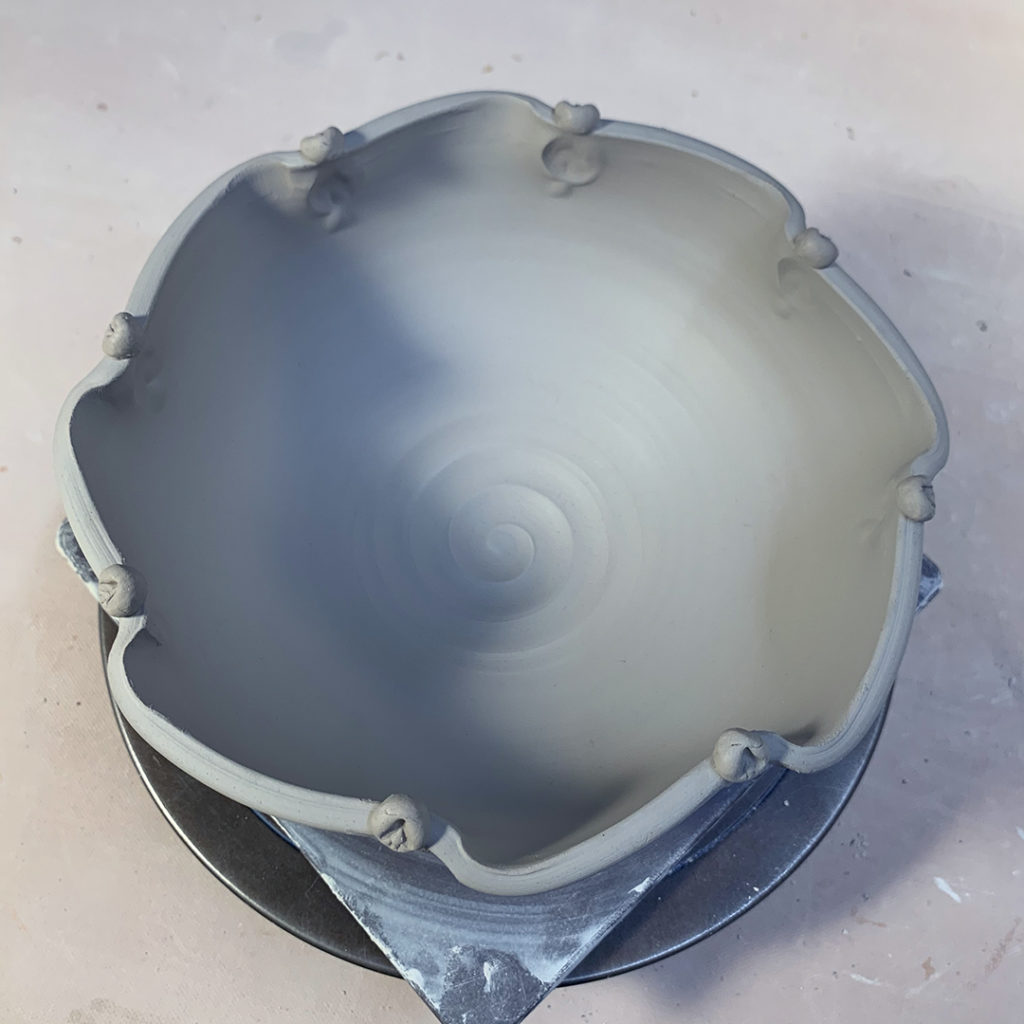

Luckily, I have more in the kitchen… as pottery classes at Lillstreet have been cancelled for tonight & tomorrow morning due to the snowstorm!!!