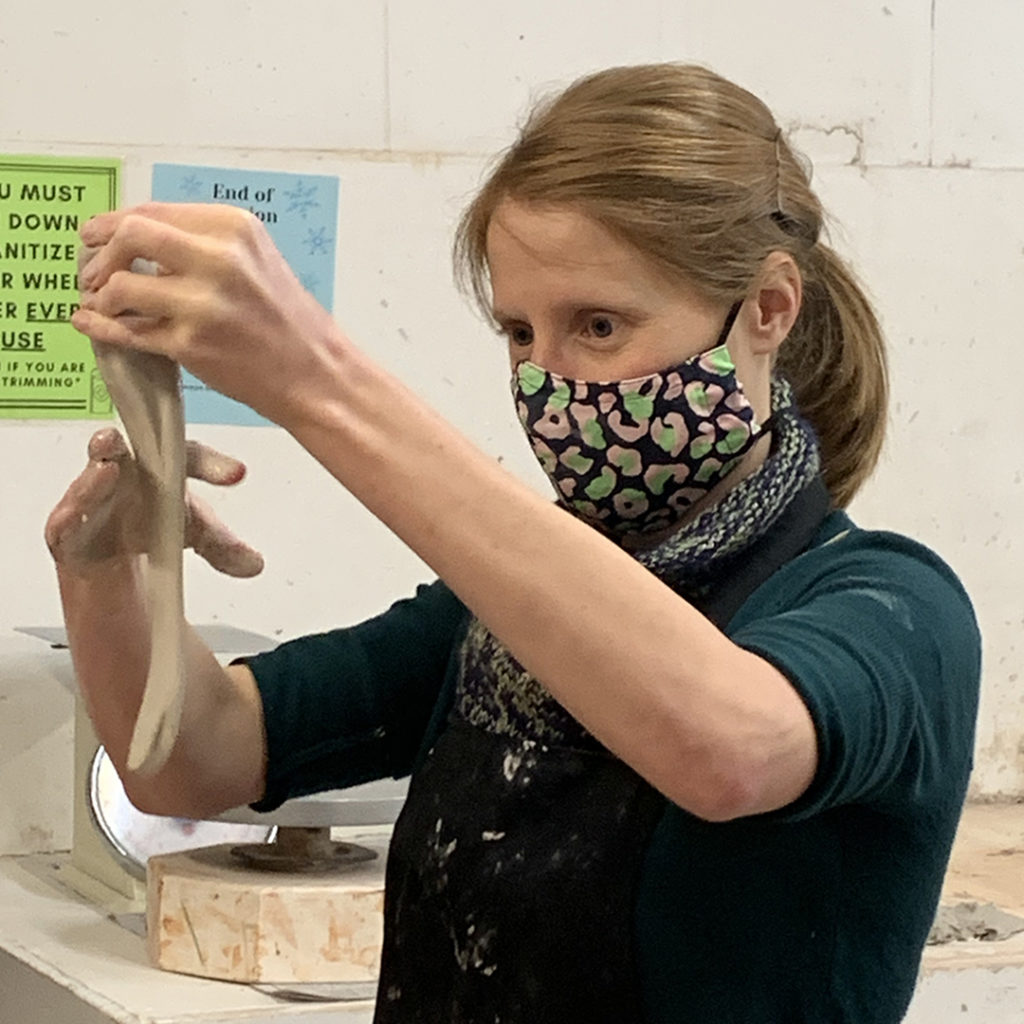

Last night in my MUGSHOT MONDAY class, my students assembled their mugs!!! It’s just a quick three-week class all about making MUGS!!! My favorite!!!

Last week they threw cylinders, this week trimming & handles… next week glazing! Very quick & lots of mugs!!! By the end of class tonight, they were “complaining†less about making handles than when we started. So I’ll call that progress… and they were all excited when they saw how many mugs they had cranked out in just a three hour class!!!