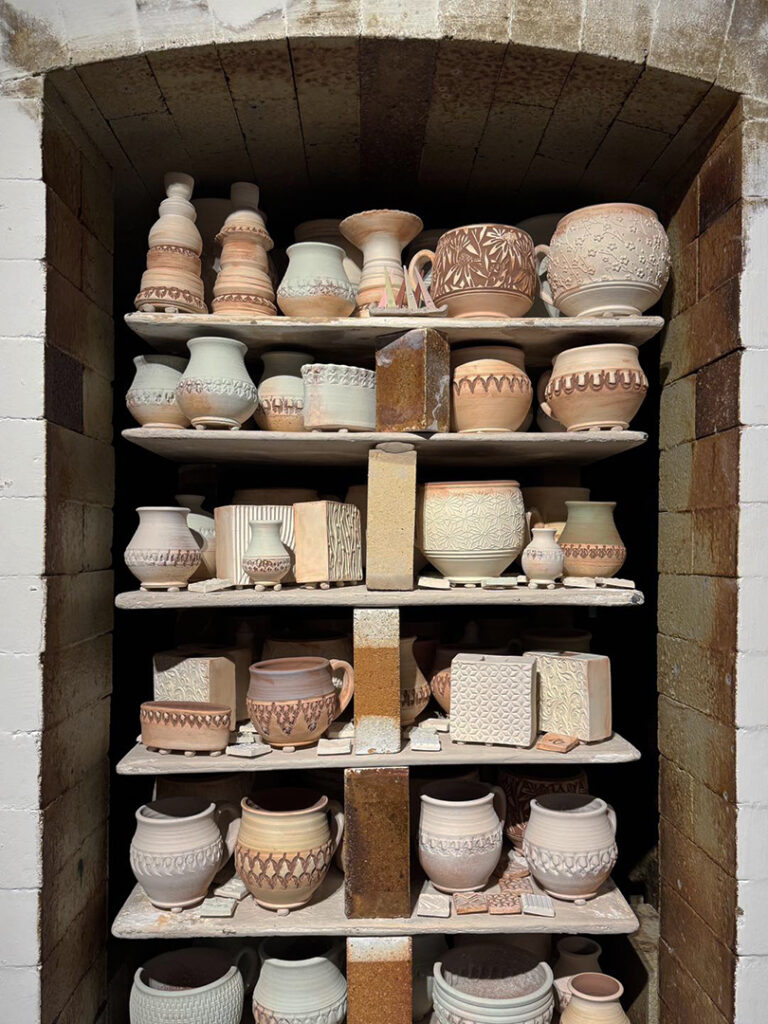

More “hybrid mugs”… with bottoms thrown on the wheel, textured slabs attached by hand, then back on the wheel for shaping & refining. And then today… back on the wheel yet again for a nicely trimmed bottom with a sharp-looking footring!!! Handles coming soon…