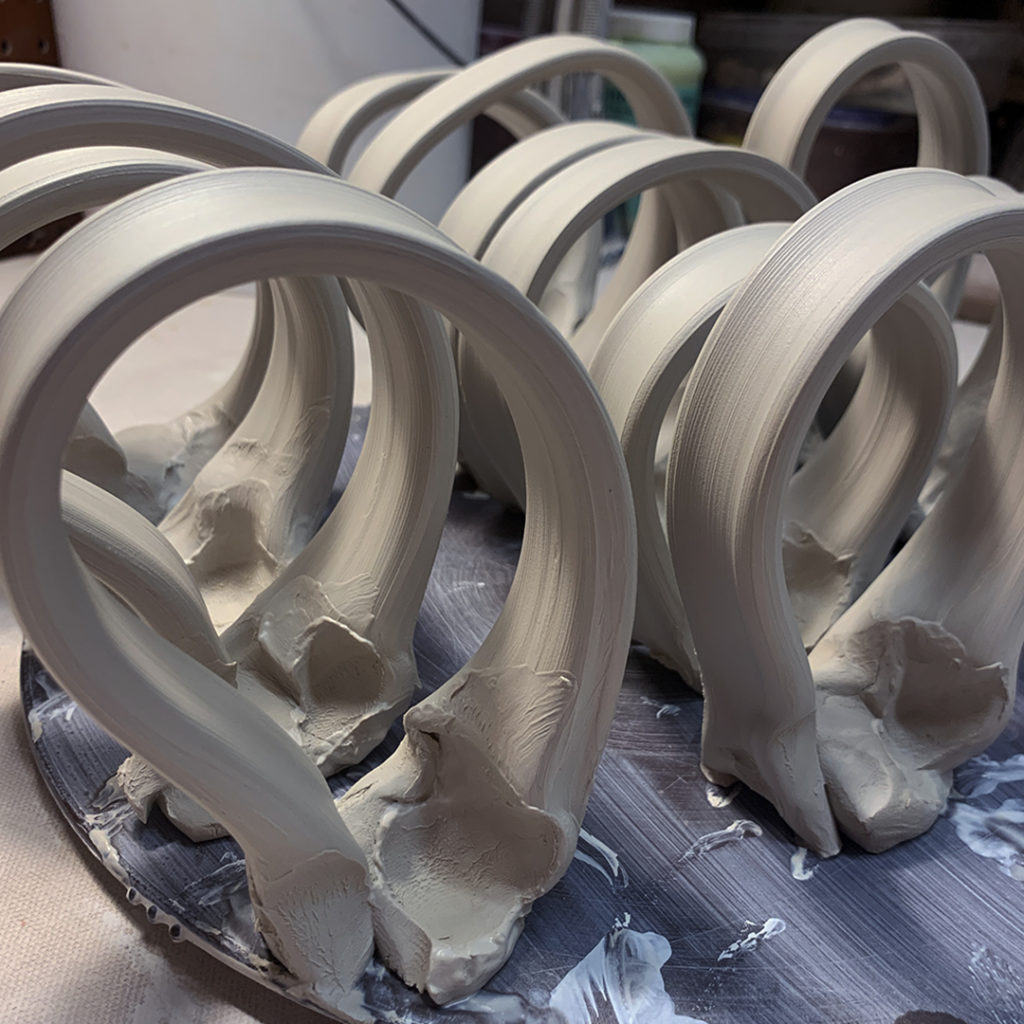

As most of you know, I hate glazing! But oddly, I totally enjoy waxing bottoms!!! A zen-like process with one clean hand & one wax hand. Wax on, wax off. Now I just need to keep my motivation alive & start glazing all of these if I hope to have them ready for next weekend’s HOLIDAY HOME SHOW!!! Wish me luck…