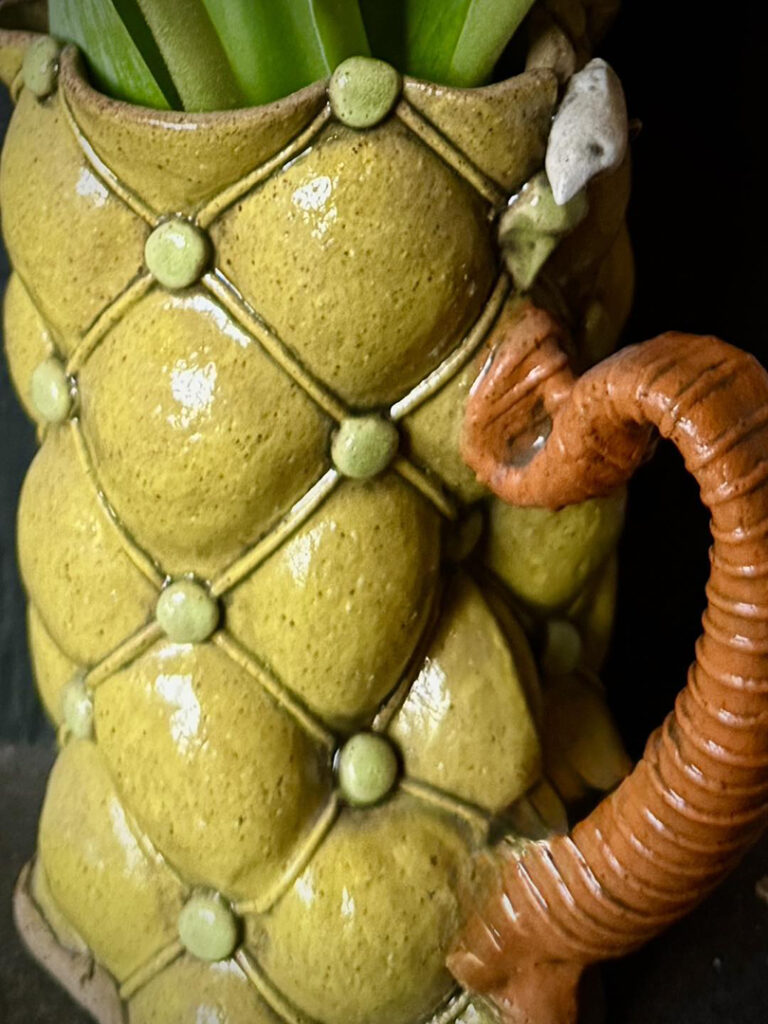

Assembled… now with handles! This latest batch of hybrid mugs finally all have handles… thus making them MUGS!!! I’m a firm believer that a “mug” by this potter’s definition must have a handle!!! So they’re all attached & ready to “relax” a little under some plastic overnight… before I come back to touch them up a bit more before drying.