And we have IGNITION!!!

Starting the day… and starting my soda kiln firing!

Gary Jackson: Fire When Ready Pottery

A Chicago potter’s somewhat slanted view of clay & play |

And we have IGNITION!!!

Starting the day… and starting my soda kiln firing!

Soda kiln firing… before & after. Side-by-side comparison of the magic

that happens in the soda kiln as the pyrometric cones melt and reach cone 10.

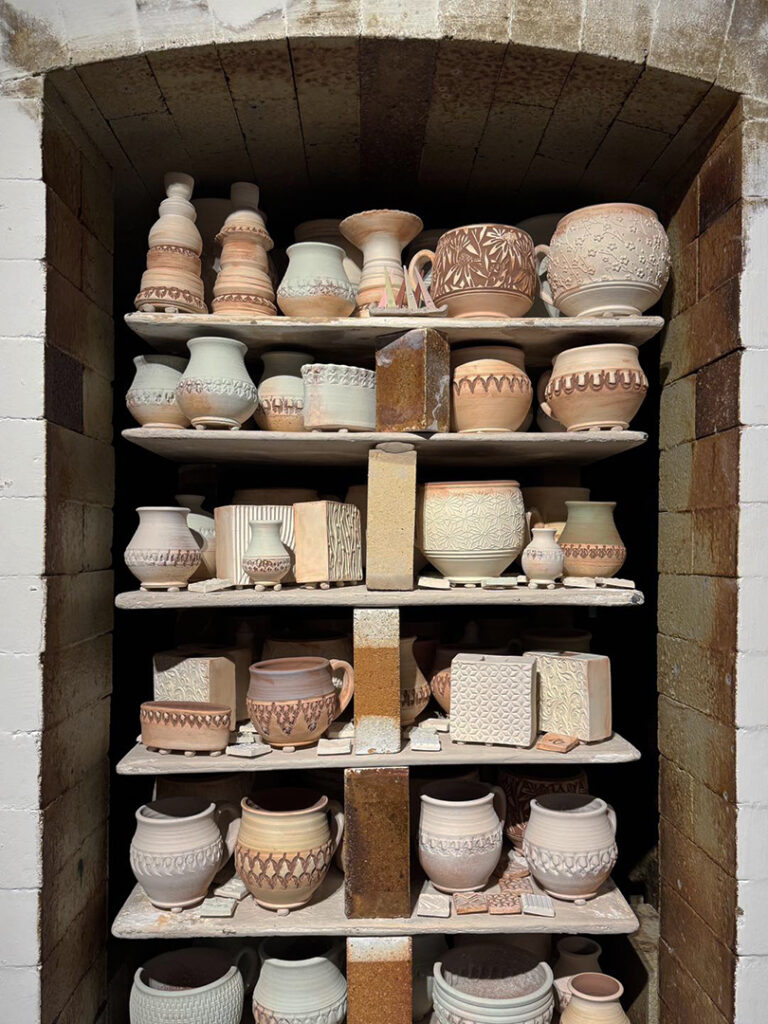

So the steel door finally came off yesterday when the kiln finally cooled down… creating ONE BIG REVEAL instead of layer-layer & brick-by-brick with the old kiln. Very exciting & everything looks great. I love when the bright colors are popping… instead of the grays & browns that usually come out of a soda kiln! It was a fun unloading… like a little pottery treasure hunt!!! More photos to come…

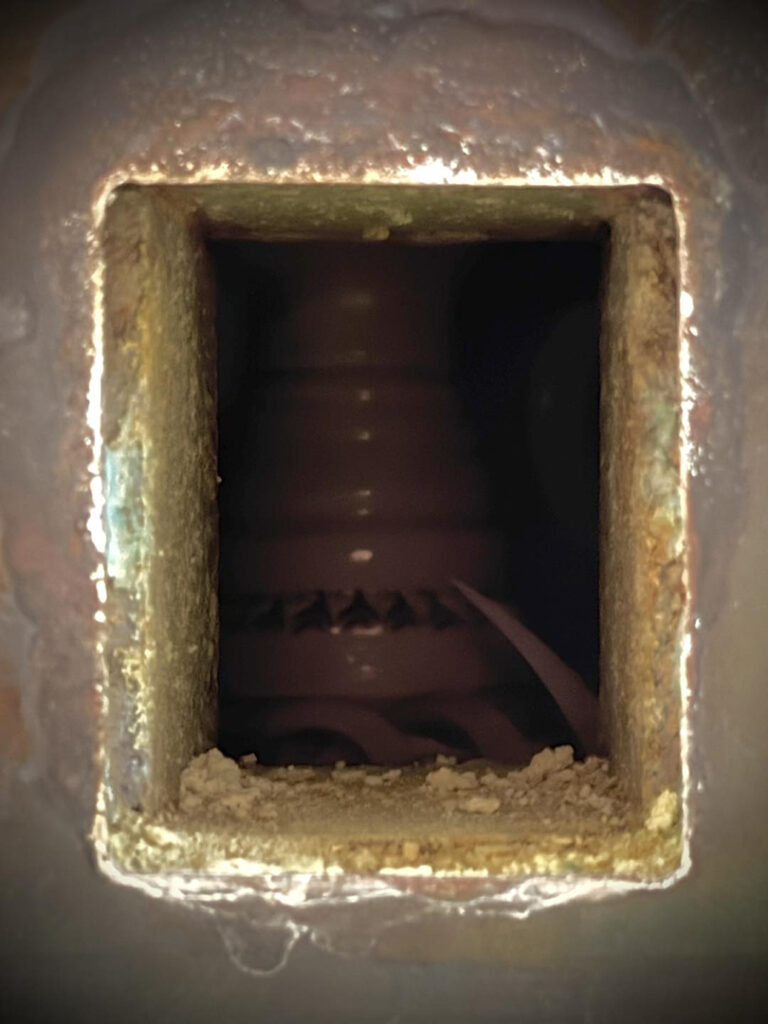

In terms of sneak peeks… this is all we get!!! With the new full steel door, I can no longer peel off the top couple layers of bricks to speed up the cooling & get better peeks into the kiln. So it’s one peep brick pulled for one peek. Guess we’re all gonna have to wait until the kiln cools enough to fully open the door!

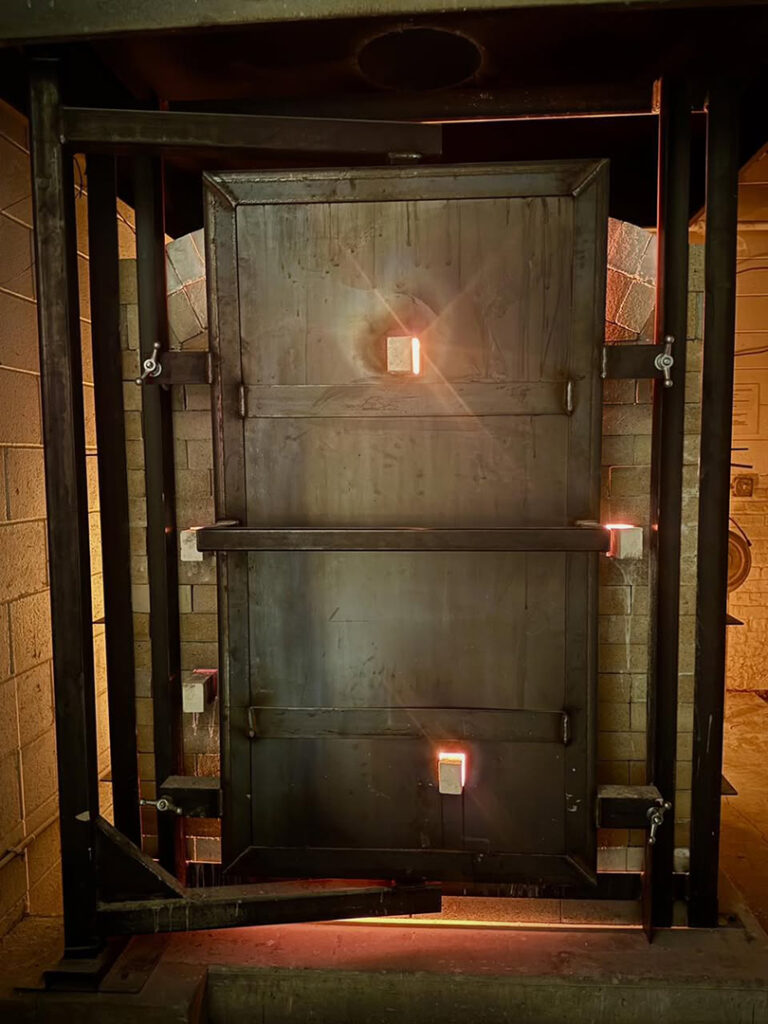

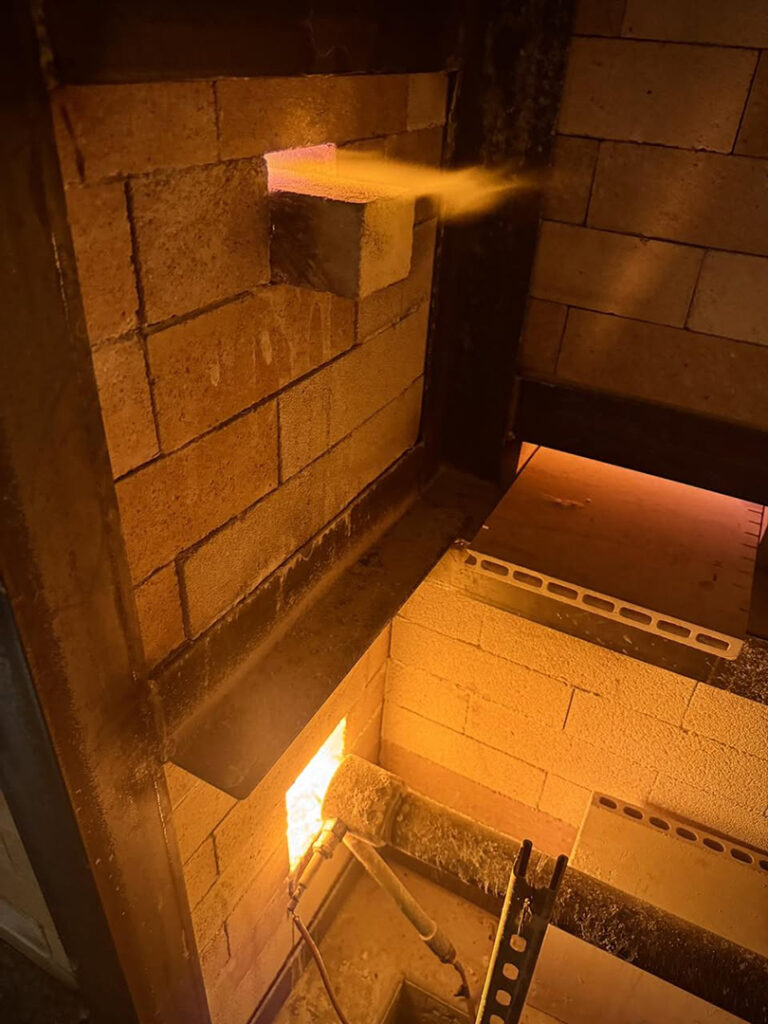

Yesterday I fired the soda kiln… a very long day checking it & making gas/air alterations. The new soda kiln has a solid steel door. So it was a little weird not having the “visual cues” that we used to have with the old “bricked-up” door. Remember the old kiln?… with crazy cool flames shooting out all over the place??? Sure, maybe not so efficient? Maybe not so safe? But it was always fun playing with the flames shooting out everywhere!!! This time, much “calmer” with a bit of a glow… and very few flames even during reduction! It all went smoothly… we’ll find out soon enough how it all turned out.

After a couple hours of loading the kiln… shelf by shelf… brick by brick… pot by pot… I finally filled all three stacks to the top. I managed to pack in a LOT of pots. Trying my best to maximize the firing fee vs. pots being fired. Hoping for good soda “glaze” coverage & some nice flashing effects. Also hoping for an easy firing in the new kiln… without too many surprises along the way!!!

While my soda kiln was in “body reduction”… I made my soda mixture for later.

Basically soda ash & soda bicarbonate.

In the old kiln, I just scooped the mixture into the kiln on a long angle iron going in through the front peep bricks… dumping into the fire box. But the new kiln has a different fire box & peep “situation “… so we can only add soda through the back peeps with a much shorter angle iron. So I had to roll-up my soda mixture in wet newspaper “burritos“ that I will add into the kiln towards the end of the firing. Dropping them in through the back on that short angle iron. A new kiln & a new technique… we’ll see?!

Last night when I made it down to the kiln room, I was “greeted” by an empty kiln full of possibilities! And the newly rebuilt soda kiln with a brand new “brick-backed” steel door! This will be my first firing in Lillstreet’s new soda kiln… so a little anxiety… a little excited… firing with fingers crossed!!!

The soda kiln has been on for a couple hours now… still warming up.

The kiln is packed tight… so it’s gonna be a long day!!! Fingers crossed….

It’s gonna get hot in there… gotta see where we’re at!!! My cone packs are ready for this weekend’s soda firing… well, two for this kiln & two for the next! Each cone melts at a different temperature… so I’ll be watching them go down throughout the day tomorrow as I fire the kiln. Pull out a brick, take a quick peek & put the brick back in! Very hi-tech, huh???

|

Gary Jackson: Fire When Ready Pottery

Lillstreet Studios ∙ 4401 North Ravenswood, Chicago, Illinois 60640 ∙ 773-307-8664 gary@firewhenreadypottery.com |