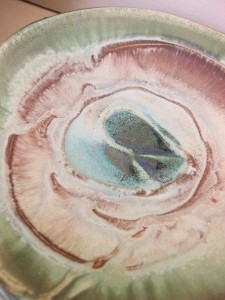

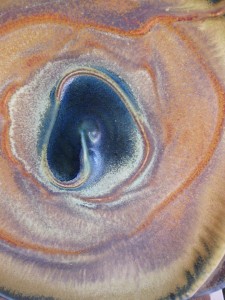

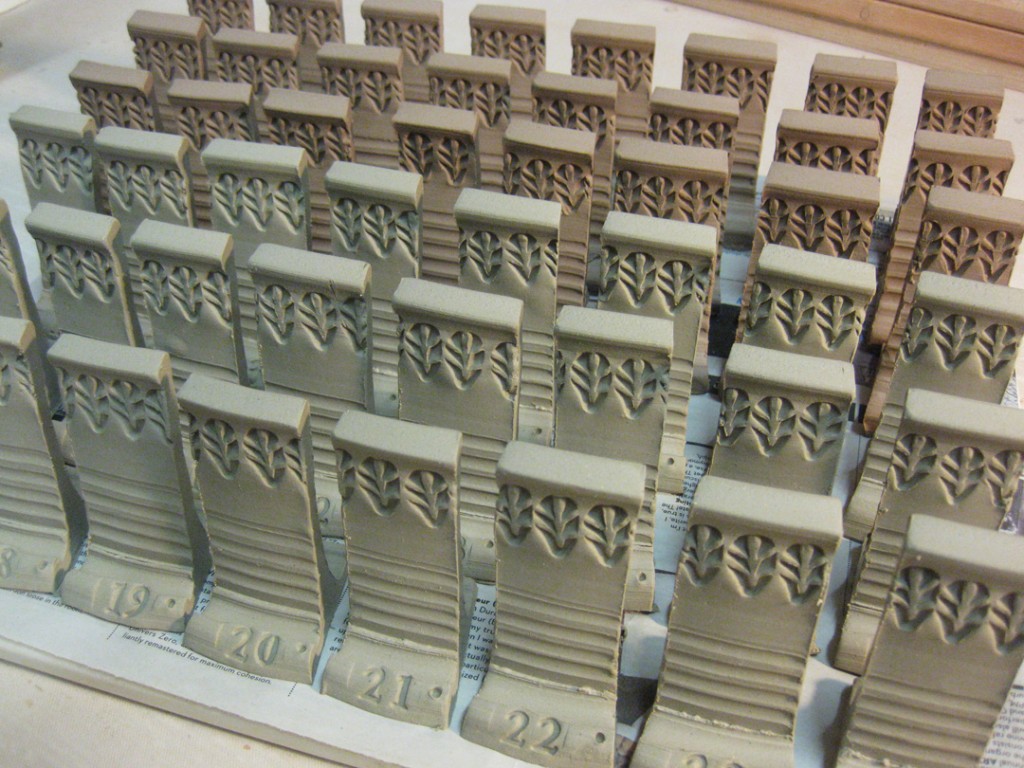

So I’ve been glazing a lot. Getting ready for my upcoming soda kiln. Glazing. Cleaning. Wadding. Getting them all ready for their trip downstairs to the soda kiln. At this point, I have one side done of my rolling cart. It’s a LOT of the smaller pieces. The ones that seem to take so much more time. But the good side is, that once my rolling cart is full of glazed work, I know that it pretty much equals a full soda kiln load. So I have one side done… more glazing & wadding tomorrow!!!

And yes, I’ve once again added on my masking tape “safety belts.” As I need to roll my cart down the hallway, take it down the rickety freight elevator, and then roll i tall the way onto the kiln room, I have found that some pots like to “jump off” the cart if you’re not careful. So a few “safety belts” help keep everyone safely in place!