Well, with my new glazes ready to go, I started glazing and loading the kiln. It’s a small electric kiln we use just cone six firings. I felt a little torn between glazing just a few pieces to test the glazes… and glazing a lot of pieces to fill the kiln. You know how I love to pack a kiln tight. And yet with new glazes, I didn’t want to glaze too many bisqued pieces just in case something goes wrong. It was a tough call. Torn between testing safely and glazing a lot of pieces – especially with two art fairs right around the corner!!!

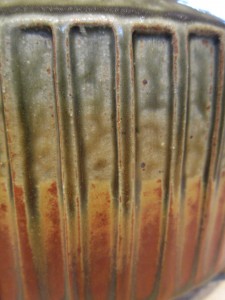

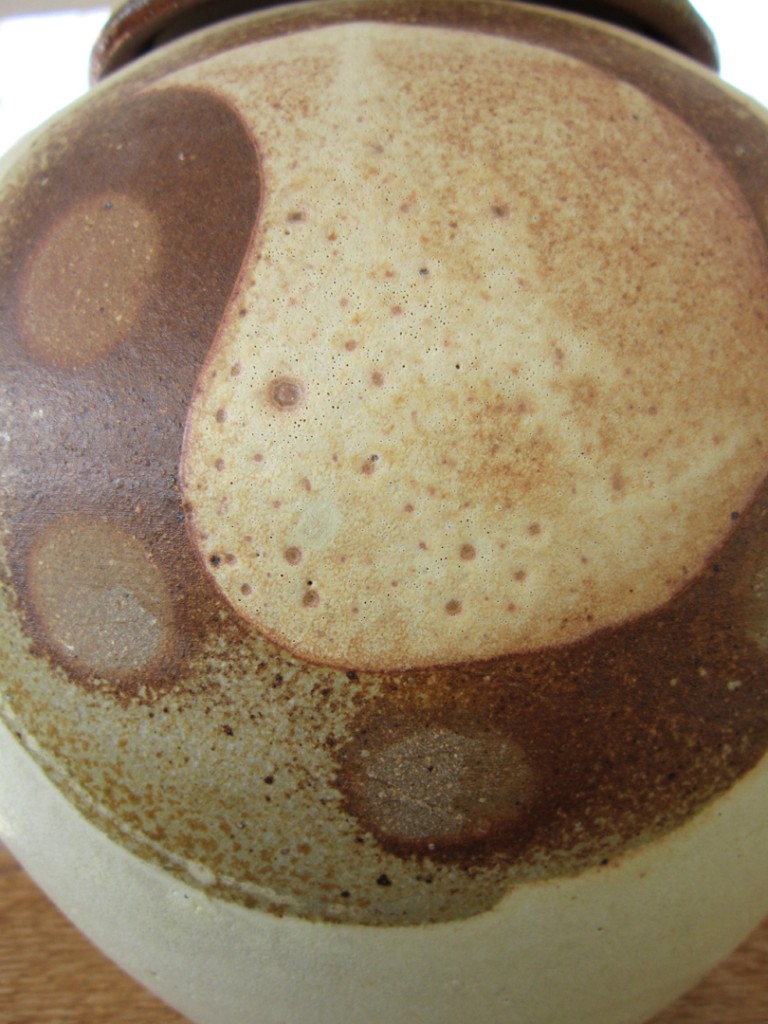

Kiln Layer #1 – mugs & soap dispensers.

Kiln Layer #2 – ikebana flower vases.

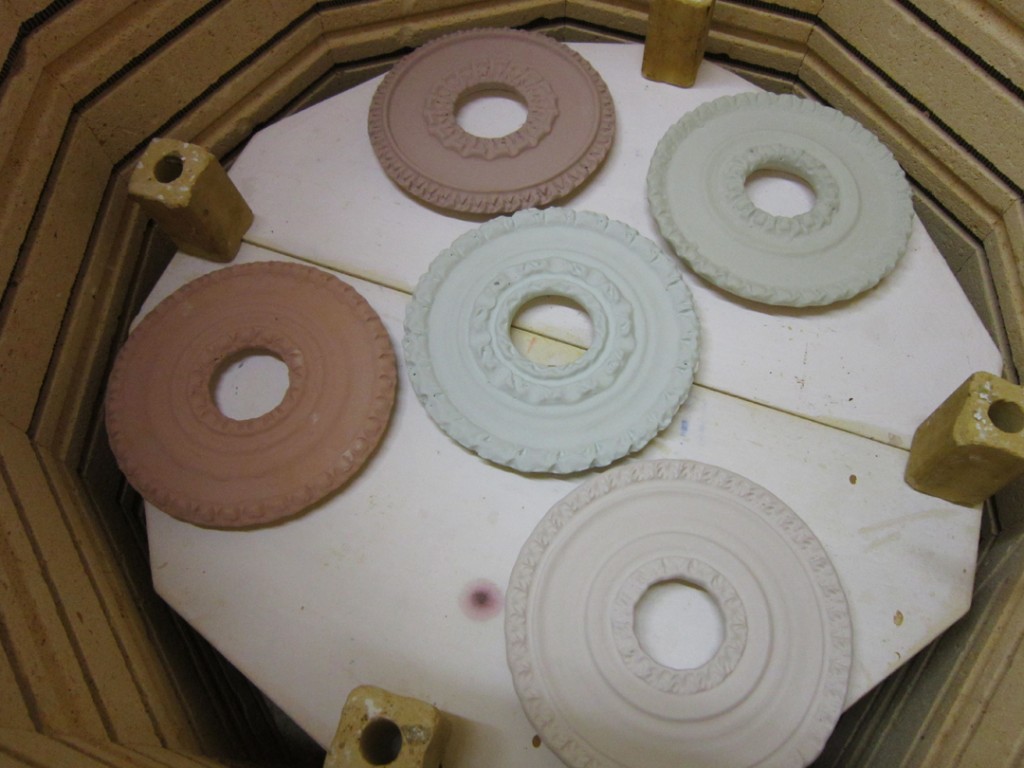

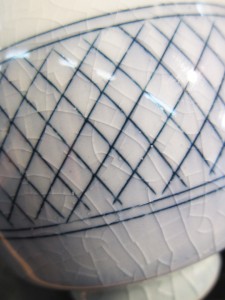

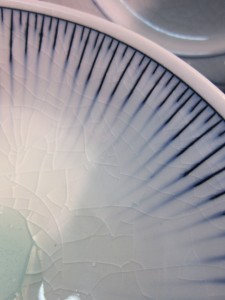

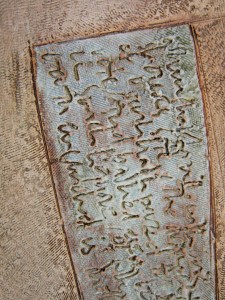

Kiln Layer #3 – bowls, spoon rests & layered glaze test tiles.

Kiln Layer #4 – spoon rests.

Kiln Layer #5 – more layered glaze test tiles & bowls.