So then THIS happened…

Last night in my Intermediate Wheelthrowing class I was doing a demo on throwing-off-the-hump. And then Christine threw out a challenge… and you know how I love a good challenge!!! More to come…

Gary Jackson: Fire When Ready Pottery

A Chicago potter’s somewhat slanted view of clay & play |

So then THIS happened…

Last night in my Intermediate Wheelthrowing class I was doing a demo on throwing-off-the-hump. And then Christine threw out a challenge… and you know how I love a good challenge!!! More to come…

Lots of clouds this morning with a damp morning haze. Beautiful reflections on the rippled water while the sun tired to burn through the cloud cover.

A SIMPLY GORGEOUS AFTERNOON!

Plenty of blue skies, wispy clouds, a swift breeze… and MY BIKE!!! Sure, I rode twenty miles this morning, but when the temperature goes up into the mid-60’s for the first time this year… you just GOTTA go out to play… for another forty miles!!! Whoo-Hoo… Spring is coming!!!

So Ive been working on some more of my “handbuilt-wheeltrown-combo” mugs. The bottoms are wheelthrown, the sides handbuilt, and then trimmed & refined on the wheel again! One of my favorite “tricks” for making fun textured mugs!

I start by making some textured slabs of clay. Sometimes with my own stamps, texture mats, or carved rolling pins… like this great one from STODOLA!!! They make tons of different rolling pin textures… including custom designs if you need that. Check ’em out at www.stodola.org.

After pressing in a texture, I cut them into straight-sided rectangles… long enough to be the circumference around the base of the cup.

I throw little “bases” on the wheel… just a small little disc wheelthrown on a plastic bat. I do NOT wire them off as I will be putting them back on the wheel to continue to the process and I want them to stay centered.

I start assembling them by wrapping the slab around the base – scoring & slipping along the way. One of the benefits of this technique is that the weight of the slab is supported by resting on the plastic bat. The extra part below the wheelthrown bottom will be trimmed off later. But it makes a great support system at this point.

Where the slab overlaps, I cut it on an angle and then connect that seam… trying to blend it together as best I can without ruining the pattern. A good “secure” seam is pretty important here.

After attaching the sides, you can spin them on the wheel and press outwards from the inside to give the cup a little curve & volume. I also give the rim a little extra attention to keep it round & smooth… like a wheelthrown cup.

I let the cylinders set-up overnight before trimming… under plastic so they dry slowly to leatherhard. At this point, they can be wired off the plastic bat.

I start by cutting off the excess slab that is “under” where the slab attaches to the wheelthrown disc with a sharp blade. Confusing a bit… as it is now “above” the connection point as the cup has been flipped for trimming.

Then I start trimming the bottom as though it were a “normal” wheelthrown cup. The Giffin Grip helps hold everything in place and centers things quickly! And my DiamondCore Trimming Tools work great for trimming a clan, crisp footring. I make sure to trim all the way into the textured slab so that it blends together and looks seamless.

Once trimmed, I let them sit under plastic while I pull some handles for them. Cups are cups… but a mug needs a handle!!!

So when the handles stiffen-up a bit, I start attaching them to the sides… usually where the seam is as a little “creative camouflage.”

I let the mugs sit under plastic overnight again so that they stiffen-up to leatherhard and the moisture levels balance out. Since these are going to be soda-fired, I decided to dip them in thin colored flashing slips. I held them by the footring and carefully submerged them into the slip to only cover the textured slab sides. I left the curved wheelthrown bottoms as raw clay. I think that the difference will look cool after soda-firing! As the slip was dripping wet after dipping, I propped them up on kiln posts so the dripping would stop before flipping them back over. I didn’t want big drippy runs going down the sides.

So now they’re drying and getting ready for a bisque firing. Once fired, I will add a liner glaze and maybe some other colored glaze accents. After soda-firing, the textures should pop nicely and the flashing slips will help accentuate the pattern.

Finger crossed.

Looks like Spring is working its way into Oak Park… and my friend & fellow potter Roberta’s backyard where the snowdrops have started to bloom. She brought a few blossoms inside for her perfect little bud vase! So pleased that my tumbler made her photo shoot! Thanks for the shout-out Roberta!

Check-out Roberta’s amazing work on her Facebook page…

https://www.facebook.com/robertapolfusceramics/

With warmer weather on the way, it sure felt like Spring is definitely coming! Almost all of our snow & ice has melted away along the lakefront… and the early morning reflections were a great way to start the day!

Birthday cake never looked so good! Sure, I might be extra hungry after my long hike today… but these photos of Rosene’s chocolate birthday cake sure look scrumptious! Yummy chocolate frosting on a stamped & soda-fired plate! Although methinks she might need a larger platter… and just asking, but where are the birthday candles?!!!

It was a beautiful day to get outside to play! The sun was out and the temperature actually hit 50-degrees!!! I decided to go for a nice long hike through Moraine Hills State Park. I was surprised by the amount of snow they still had, but was happy to be shedding layers of clothes as the day went on. Some beautiful scenery, slushy paths and a few sandhill cranes along the way!

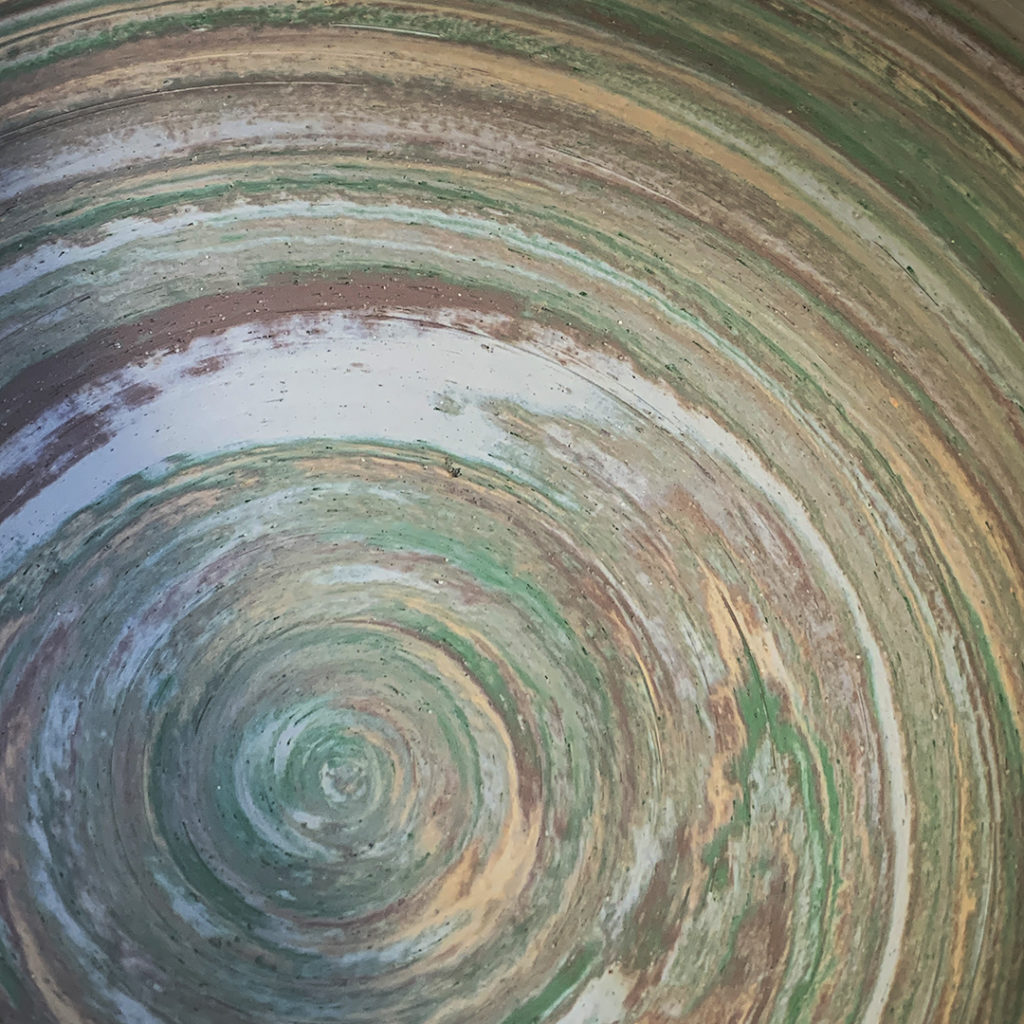

Another example of cool marbled clay after trimming! Lots of layers of colored clay all mixed together!!! Works well as long as all of your clay bodies have the same shrinkage rate!

Another marbled clay class demo… this time with white porcelain & green-stained porcelain! Looking a little blurry after throwing, but as I trimmed the interior & exterior “skin” away you can see the layers & marbled effects. Trimming with my DiamondCore Tools made it easier with their T2 Arc Trimming Tool that has a great curved blade to get inside with ease… worked outside too!

|

Gary Jackson: Fire When Ready Pottery

Lillstreet Studios ∙ 4401 North Ravenswood, Chicago, Illinois 60640 ∙ 773-307-8664 gary@firewhenreadypottery.com |