It was a long wait today… as the kiln temperature dropped ever so slowly.

I kept opening it slowly to “encourage” the cooling process; being careful

not to open it too quickly. When it got to about 250 degrees, I felt it was okay

to unbrick the door. And then it was time to start unloading the kiln.

Like a little kid on Christmas…

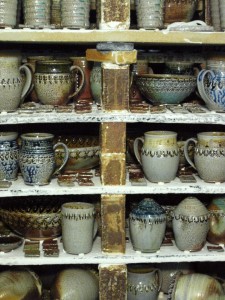

It’s always fun to unload the kiln – to see the results of your hard work. And to see how

things have been transformed during the atmospheric firing process. It was a very

tightly packed kiln. I was concerned that there may be some “dry patches” in the kiln

because it was packed too tight… luckily the soda made its way through the kiln and hit

everything quite nicely… if I do say so myself. Only two mugs were on the “drier” side.

All in all, it was a great firing with great results.

But then, after unloading and packing everything into boxes to get it home…

I still had to clean the kiln, scrape & kiln wash all the shelves, sweep out the fire box

and all of that fun stuff that comes with maintaining the kiln! Exhausting…

This morning’s sunrise was beautiful. Quiet. Serene. And not too chilly.

A beautiful glow on the horizon down on the jetty by North Avenue beach.

After the sun peaked out, and I had taken my sunrise photos…

I turned around to enjoy the beauty of the Chicago skyline as well.

On the way home, I stopped in at the studio to check on my soda kiln.

And it was well over 500-degrees – still kinda toasty!!! So I pulled the peeps

and took off a layer of the bricks along the top arch to help speed up the

cooling process. I’ll go back in a few hours to open the damper, work in the studio

for a few hours, start gradually unbricking… and hopefully get it cool enough

to unload later this evening! I can’t wait…

I just stop in at the studio to check on my kiln… and it is still over a thousand degrees!!!

Too hot to pull the peeps to get it cooling a little quicker! With a LOT or work and

a LOT of shelves, it’s going to take a little longer than usual to cool. Ill check back later

tonight to get the cooling process “officially” started.

Today was firing day. A long day. But worthwhile when I get to open it in a couple days!

So I started early this morning by “pumping the flames” into the kiln. There are two burner

ports on the back of the soda kiln, one on each side of the chimney. It starts up slowly,

with gradual increases in gas & air to ramp it up for the first couple hours.

About a half-hour into it, I came down for the first turn-up, checked the kiln,

checked the flames, checked the reduction, checked the cone packs… only to be

surprised to find that the bottom cone pack was gone!!! Missing. No signs.

My guess is it must have exploded or fallen off the shards that held it in place.

Luckily, I rely on the top cone pack a lot more than the bottom.

During the firing, you’re “trapped” at the studio… can’t leave, can’t really start much

as you need to check the kiln throughout the day. So it’s a lot of finishing little projects,

cleaning, sweeping, dusting, trimming class demo’s, chatting and waiting for the kiln.

When the kiln finally begins to reach the top temperatures, it’s time to mix up the

soda mixture that will be introduced into the kiln. Who knew that such a “sloppy mess”

of soda ash, soda bicarbonate, whiting, wood chips & water could make your pots

look so great?! It looks like an odd mix of oatmeal & tuna?!

When the kiln is around cone 9, I start introducing the soda mixture into the kiln

on an angle iron. Dropping soda mixture into the kiln every 15-ish minutes until the mixture

is gone. Tonight I also had two assistants putting the soda in. Two of my beginning wheel

students were there working and had never really seen a kiln firing before. So I offered

to show it to them, and even let them put some of the soda in. Pam was surprised

how hot it was back by the kiln, and Chuck had that instant look of “pyro-addiction.”

He loved putting the soda in… the flames, the heat, the danger… he’s in!

And I loved having the help. After the soda is introduced, the flames come shooting out

of the peeps as the atmosphere inside the kiln is quite volatile – with the evaporated soda

mixtures flying all around the kiln and hitting the pots inside!

After all of the soda is in, I let the kiln continue longer so the soda can “soak” and spread

a little more as it gets to it’s top temperature and cone 10 finally drops! During that

soaking time, I had a chance to hang out with Chuck & Pam… and had to laugh at the

persistence, dedication & focused attention Chuck had as he was applying slip to one of

his pots! Not bad for one of my “tile-class-convert” wheelthrowing beginners, huh!!!

After a good soaking, it’s time to turn the kiln off… and it’s suddenly silent.

Turn off the gas. Turn off the blowers. Turn off the exhaust fans. Close the damper

and call it a night. Now it’s time to wait again… as a watched kiln never cools!