Another quiet morning without a lot of sunrise drama.

Just a few simple clouds floating quietly along the horizon.

Gary Jackson: Fire When Ready Pottery

A Chicago potter’s somewhat slanted view of clay & play |

Another quiet morning without a lot of sunrise drama.

Just a few simple clouds floating quietly along the horizon.

After a full day of Summer Camp… followed by an evening in my studio… I felt that I “deserved” to celebrate NATIONAL HOT FUDGE SUNDAE DAY when I got home!!! … burp.

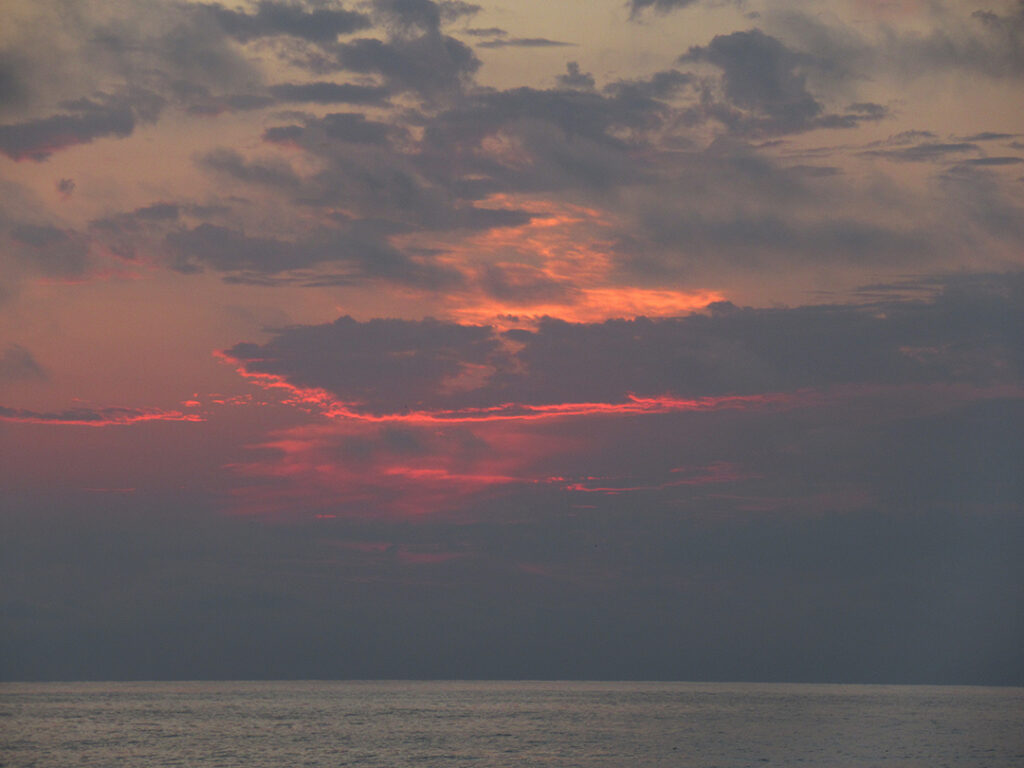

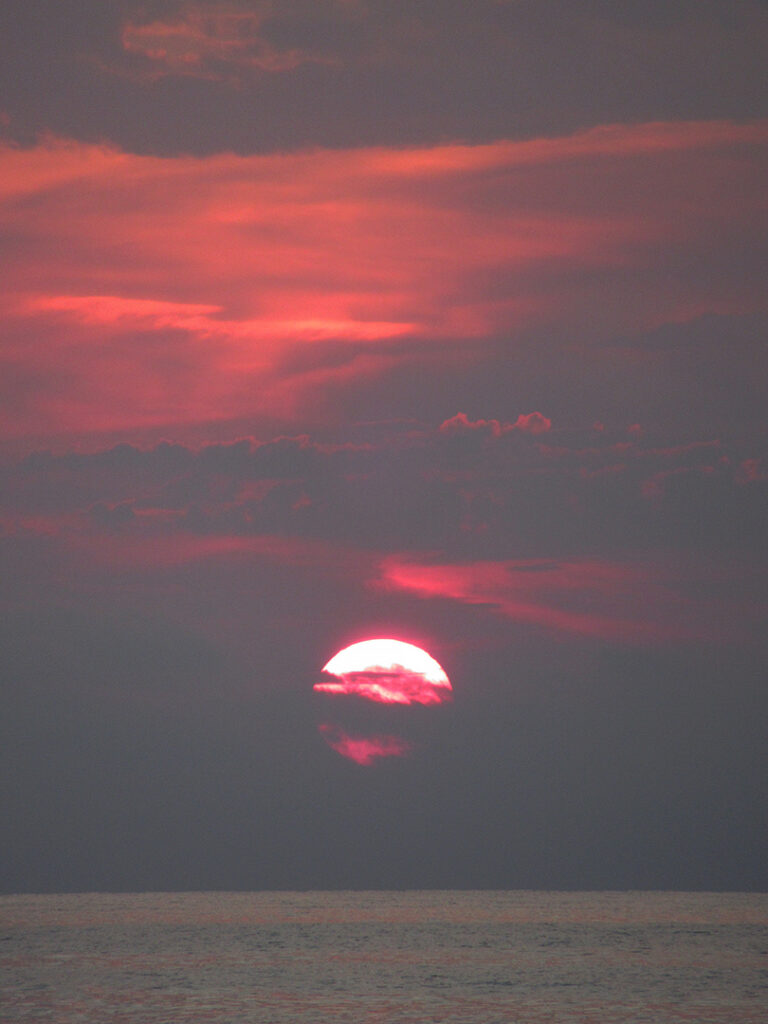

With gently breezes blowing in off the lake, the clouds were spotty

& catching the colors nicely as the sun continued to rise

Kristy sent me a picture of her breakfast this morning… some vibrant fresh tabbouleh salad. Not my first choice for “breakfast”… un, waffles?!… but it does look pretty yummy in a fun stamped aubergine bowl. Thanks for the photo Kristy!

Last night with my Beginning Wheel class, we did some glazing… as well as a demo on how to throw taller & get evenly thin walls. I did my demo & explained how to do it… but there’s really only one way to really see how well you did. So I cut it in half!!!

So apparently… & inadvertently… one of my class demos tonight was to show my Intermediate Wheel students how to throw on a plastic bat with only ONE corner actually on the bat pin!!! Wait, what?!!!

Yes, I put the bat down on the chamois bat-grabber & proceeded to throw a well-centered little cylinder. Only after throwing did one of my students realize that only one corner was affixed on a bat pin!!! It was OFF the entire time! HA!!!

Yeah, great demo, huh???

This just in… and perfect for another MUGSHOT MONDAY!

“Gary, Just bought my mug in Glenview yesterday and today I shared some tea with my giraffe collection. I love my new mug. Thanks for making it!” – Marcia

A huge THANK YOU to everyone who stopped by my booth in Glenview this past weekend. I had so much fun seeing everyone, chatting with a bunch of pottery fans & watching a LOT of pottery go off to their new homes! We had amazing weather both days… especially under my shade tree with a nice cooling breeze!!!

And I always find it funny when the tops of the skyline disappear into the clouds… because I’m always thinking of those people who paid a ton of money for their gorgeous view of the City… and it’s GONE today!!! Waking up to sheer grayness everywhere they look out through their expensive windows!!! HA!!!

Quiet waters & shimmering reflections… that’s how I’m gonna sum it up today.

|

Gary Jackson: Fire When Ready Pottery

Lillstreet Studios ∙ 4401 North Ravenswood, Chicago, Illinois 60640 ∙ 773-307-8664 gary@firewhenreadypottery.com |