Sure, the sides of my “hybrid mugs” might be handbuilt… but the bottoms of the mugs are trimmed on the wheel for a cleaner & more professional finish. Now I just need to figure out something to make out of these “rings” as they get trimmed off?

Gary Jackson: Fire When Ready Pottery

A Chicago potter’s somewhat slanted view of clay & play |

Sure, the sides of my “hybrid mugs” might be handbuilt… but the bottoms of the mugs are trimmed on the wheel for a cleaner & more professional finish. Now I just need to figure out something to make out of these “rings” as they get trimmed off?

So the cylinders that were thrown yesterday were ready today to start stamping. They were under plastic overnight so now they are at a good stage that I like to call “wet-leatherhard.” Not quite stiff enough to trim yet, not quite wet enough to be squishy or sticky… but instead firm enough to hold its shape, and yet wet enough to press in good impressions with my handmade stamps.

Mug #1 –

Mug #2 –

Mug #3 –

Mug #4 –

Mug #5 –

Mug #6 –

Mug #7 –

Mug #8 –

Mug #9 –

Mug #10 –

Mug #11 –

Mug #12 –

Mug #13 –

Mug #14 –

Mug #15 –

Mug #16 –

Mug #17 –

Mug #18 –

Mug #19 –

So for now they’re all back under plastic wraps… drying up a bit more until they are leatherhard and ready for trimming. And then… the ever-popular task of adding handles to all of them!!!

Lots of stamping… lots of patterns… lots of textures! Always fun using my own handmade clay stamps to create the surfaces on my mugs. All pressed in one by one… by one… by one…

Well, it looks like I’ve got a good bit of trimming ahead of me today… hoping to get it all done before teaching class tonight?! A bunch of bowls at a good leather-hard state ready for trimming… one of my favorite parts of the whole process!

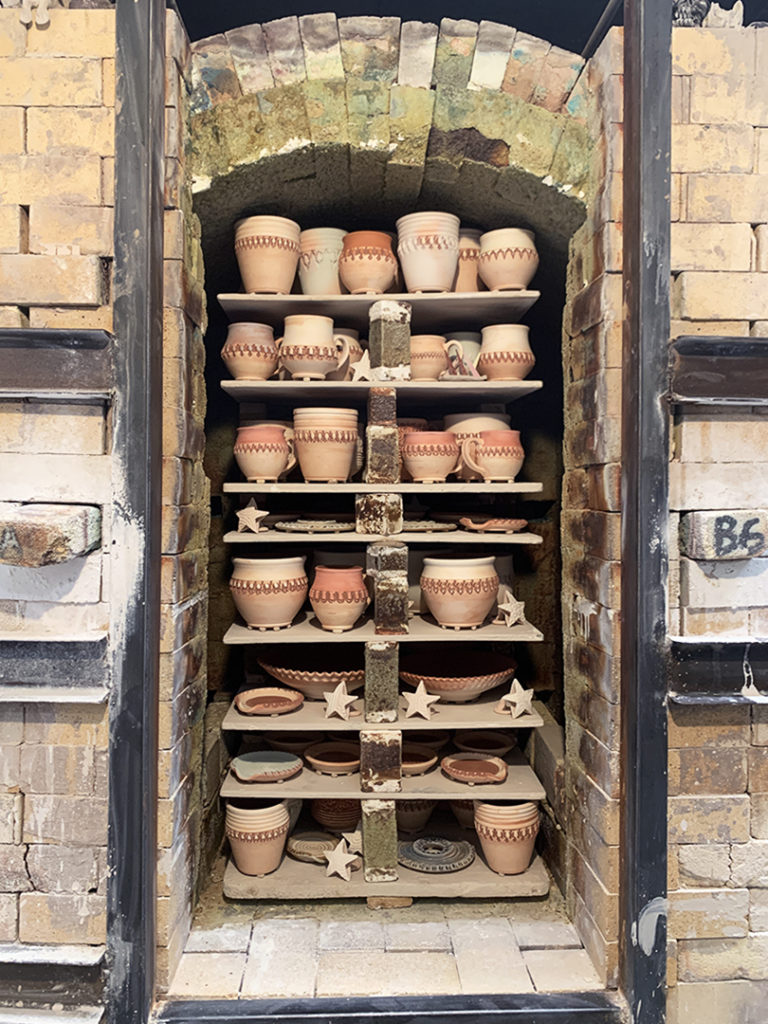

All loaded last night… a LOT of pots fit in this time! Feeling pretty good as I got everything loaded…. except for about five mugs that didn’t quite fit! Can’t wait to see how these pots “magically” transform during the soda-firing!

Like glazing wasn’t “fun” enough already… ugh… I also need to add little balls of wadding to the bottom of every pot being loaded into the soda kiln. Wadding is basically a soda-resistant clay that will help keep my pots from sticking to the kiln shelves after the soda-atmosphere adds a layer of glaze on everything!

This batch of stamped mugs now has inlaid glaze in all the stamped impressions.

Next up?… tenmoku liner glazing! I like to work in an “assembly line” kind of process.

Finish one step, then move onto the next.

Glaze on… glaze off. Busy putting tenmoku glaze into the stamped impressions on my mugs. I like how the dark inlaid glaze really makes the stamped textures show up so much better!

Definitely feeling the Spring vibes here with some colored slip accents on my bisqued mugs. Getting ready start glazing these… inlaid glaze in the stamps & a tenmoku liner glaze. Then it’s off to the soda kiln this weekend where these colored slips will react & flash with the soda atmosphere during firing. The colors should become darker, richer & more saturated… if all goes as planned?!

Plenty of bisque piling up waiting to be glazed & wadded. First-up… inlaying a tenmoku glaze into the stamped impressions for high tener contrast after the soda-firing. Here we go… giddy-up!

|

Gary Jackson: Fire When Ready Pottery

Lillstreet Studios ∙ 4401 North Ravenswood, Chicago, Illinois 60640 ∙ 773-307-8664 gary@firewhenreadypottery.com |