I spent the afternoon in the studio trying to finish up some pieces with a few slip details.

As if the obsessive stamping weren’t enough, frequently I also go back and add a dab of

colored flashing slip into each stamp. I love how the soda firing makes these colors pop,

and adds another layer of interest into my work.

Who doesn’t need a little more obsession in their life anyway, right?!

Last Tuesday, I did some repeat demos for my class for those that missed them

the first time… or didn’t find them quite as easy when they tried to do them!

Totally fine by me. It’s their class and I’m more than willing to demo whatever they want.

And now I find myself with another demo platter thrown and waiting to be stamped.

Well, tonight was the night. First, I started by unwrapping the original platter which was

finally to a good state of leather-hardness to be stamped… just a little softer than

“trimming leather-hardness” typically is.

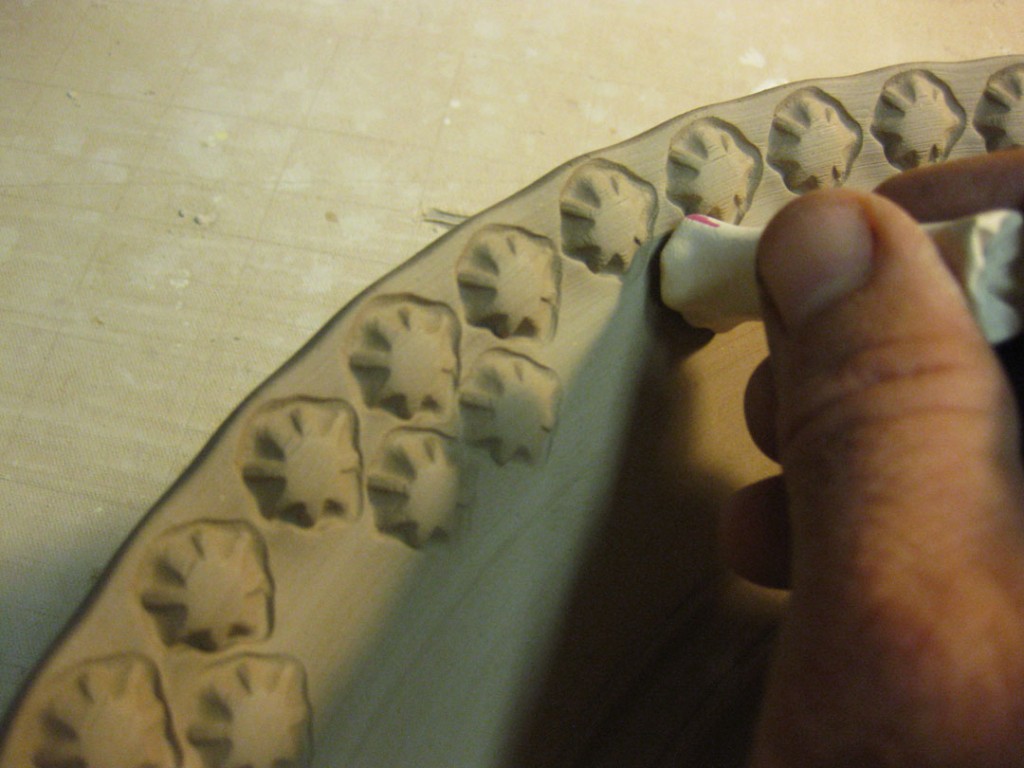

Then I start by making the first row of impressions with the chosen stamp pressed in one,

by one, by one, by one… again, and again, and again… until you get all the way around

to the other side! And I always have my fingers crossed that they’ll line up just fine!!!

Then it’s time for a second row of stamps to start the pattern…

After a couple more stamps, and a few smaller accent stamps at the bottom of each point

and the stamping portion was done.

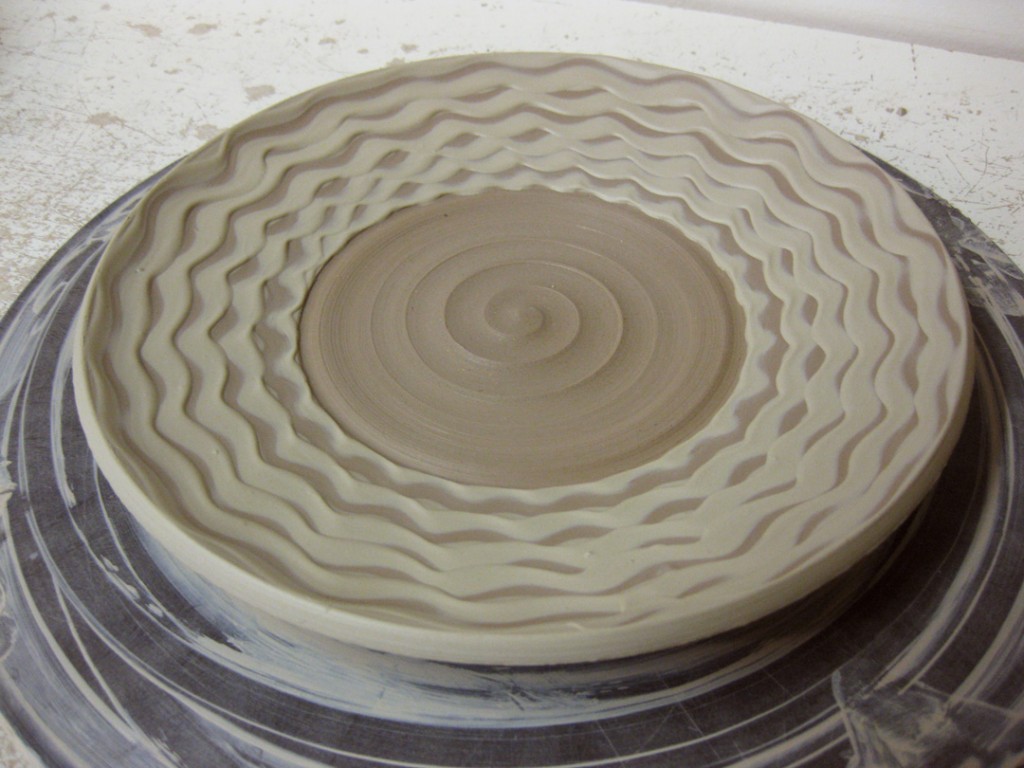

Then it was time for a little rim fluting & curving to give the platter a gentle undulating

design. A simple touch to give the platter a completely different look.

Here’s a close-up of the curved rim – just before wrapping it up with plastic for the night.

So now it’s a waiting game until it is dry enough for trimming.

So here’s the platter I threw for my class demo last Tuesday night.

I was hoping to keep it wet enough to stamp it as “class demo part two” next Tuesday.

But it was getting a little too dry a little too quickly. So I had to stamp it today. Here’s the

“demo” I was planning to share… this time in a sequential photo format.

The chosen stamp prepared to make its mark on the platter!

Just getting started… pressing the stamp into the moist clay one, by one, by one…

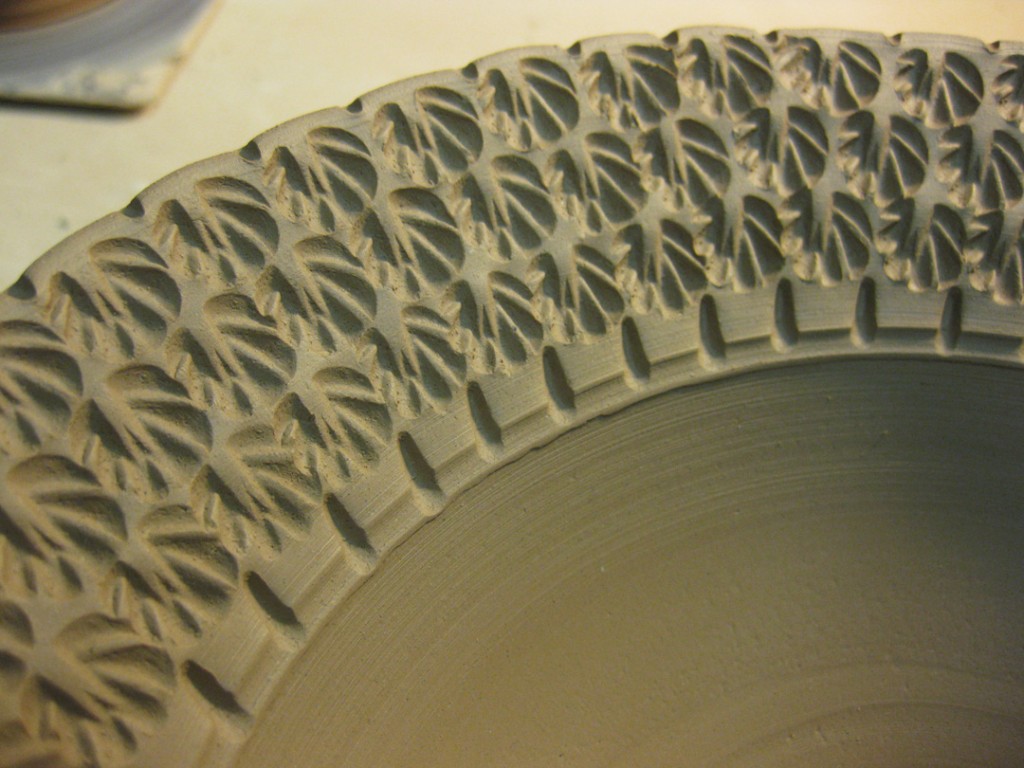

One row of stamping done. I always love to see how a basic platter can be transformed

so quickly with just a few impressions!

And if one row is pretty, a second row can only make it prettier, right?!

But why stop there? So I finished it off with some scalloped edge stamping. And some small

detailing with notches in the rim and small indentations in the stamps at the points.

Here are the three tools that did all the work… a stamp, a wooden tool… and my hand!

The trouble with throwing twenty-four cylinders and stamping them for mugs,

is that at some point you need to make twenty-four handles to put on them.

Tonight was that night. Two dozen handles. Two dozen attachments. Two dozen mugs!

So I started with some wedged B-Clay to match the B-Clay cylinders.

I cut them into small chunks, then threw them down towards my wedging table

at an angle to create a slight carrot-shaped wedge of clay.

Then I started pulling the handles in the traditional way. Kinda like milking a cow!

I typically pull them into a nice strap shape, then add a little concave curve to the front

side of them. When I get them to the right width & thickness, the do a quick flip-over

and stick it to itself. That way I create a nice “pre-established-mug-handle-curved-shape”

to let them set-up in the right form. Waiting a few minutes until the are a bit stiffer and

no longer wet, shiny or squishy!

I then start attaching the handles to the mugs by cutting out the portion I need of each strap.

A little scoring & slipping on each to attach them to the mugs. After several mugs, with a few

Olympic moments on my TV, I finally got to the end of all twenty-four.

Then it’s just a quick misting of water and wrapped up for the night. I always like to let them

“even-out” their moisture levels between cylinders & handles before I open them up and let

them dry. So tomorrow night, I plan on painting some of them with a bit of decorative colored

slip and then they’re off to the drying rack.

Tonight in my beginning wheel class we tackled basic glazing techniques…

and then continued our throwing demonstrations with plates & platters.

I showed my students how to throw the plate. Then we discussed how plates are pretty

easy to throw… starting with a wide, low, flat cylinder… but tougher to trim & dry properly.

3-pound plate with white slip decoration – squiggled while still spinning!

6-pound platter… pretty plain now, but soon will be stamped which is no surprise!

So last night was my “basic bowl” demonstration for my wheel throwing class!

We were working on making each bowl different and unique. After class, I brought them

all upstairs to my studio so that I could do a little more work on them. So today after camp,

I spent some time refining & stamping the bowl samples. It will be fun to show my students

how they’ve all been transformed seemingly “overnight.”

This first bowl has a flared out rim… plain & flat until you add some stamped fun!

This second one has the same flared rim, but with the addition of fluted curves. A simple

ring of stamps keeps the gently undulation of the rim intact without overpowering it.

This third bowl had a simple, solid layer of white slip inside. Kinda plain & boring.

But a quick textured rim makes all the difference. One stamp… again, and again, and again!

One of my students asked about a “squared-off” bowl form, so I took the split rim and

literally pulled out the corners to create a square-ish bowl. But it seemed a little predictable.

So I decided to highlight two opposing sides as a “canvas” for some fun stamping,

and changed the split rim on those same sides!

With a wider flanged rim, I originally though I was going to stamp the whole thing.

But then I thought “hey, I do that all the time.” So I forced myself to try something a

little different. Nice… but I’m not quite sure if I like it or not?

So there it is, the demo behind the demo. The “magic” that occurs in my studio after class

ends. The bowls are still wrapped overnight and waiting to be trimmed and finished. I may

actually add some more “fun” to the bowls before they done and ready for the bisque kiln.