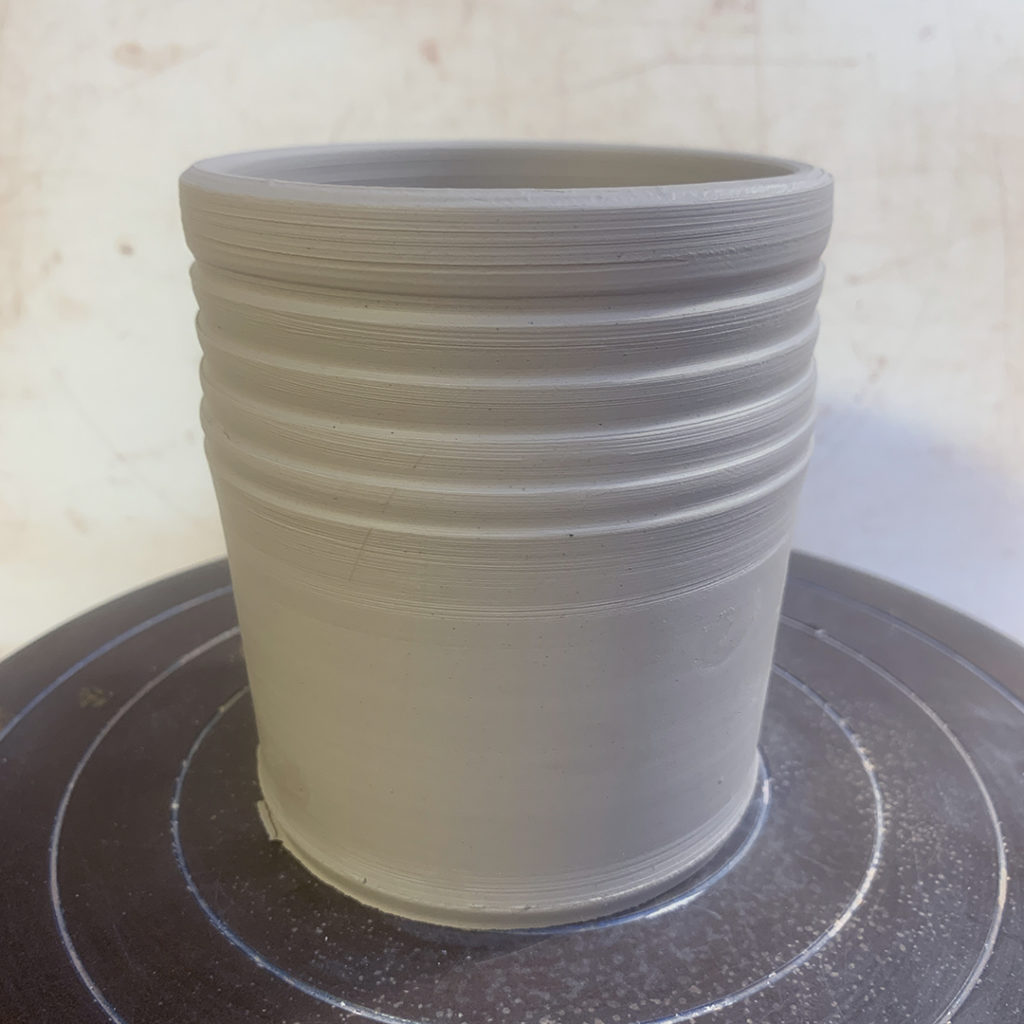

Finally got around to wedging up my pile of reclaimed clay! It sat on my large plaster bat for awhile as the extra moisture evaporated & the clay was finally stiff enough to wedge. So a little “elbow-grease” and now several bags of FREE CLAY!!! My favorite kind of clay!!!