Looks like my cousin Kim has some happy plants… especially that clover plant that’s thriving in a handmade & stamped flower pot!

Gary Jackson: Fire When Ready Pottery

A Chicago potter’s somewhat slanted view of clay & play |

Looks like my cousin Kim has some happy plants… especially that clover plant that’s thriving in a handmade & stamped flower pot!

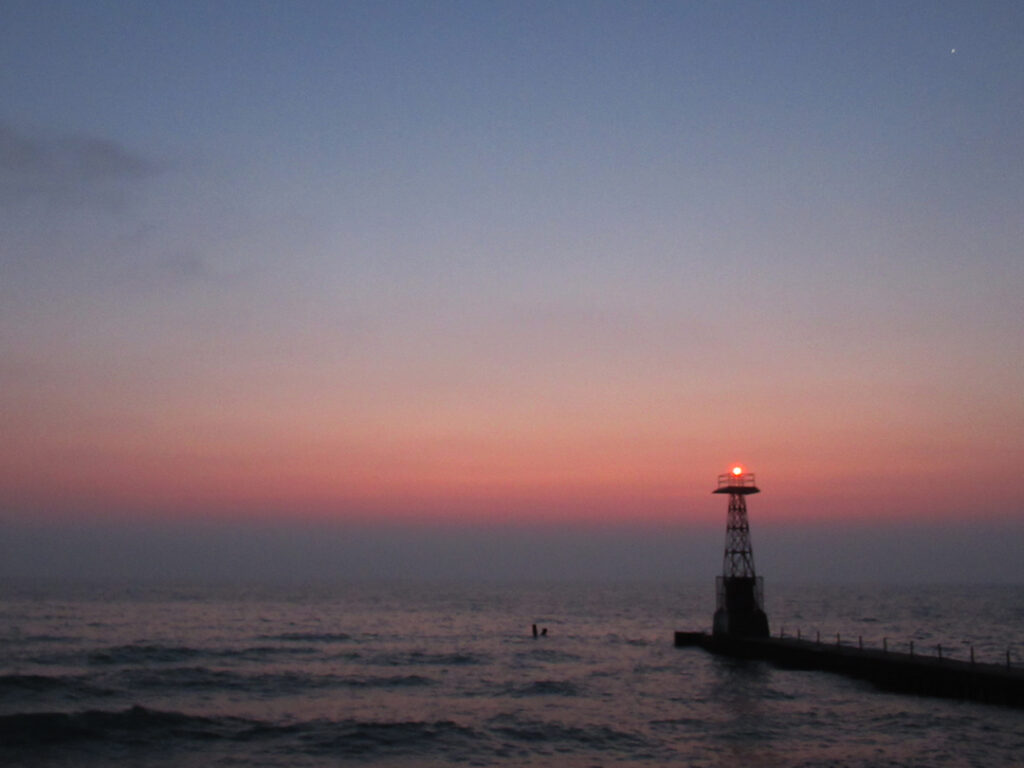

Another splashy morning along the lakefront. Humid & hazy to start… only to be overshadowed by some fun waves splashing up & over the “cement beach” along Oak Street Beach.

Celebrating a little Texture Tuesday with layers of paint, rust & who knows what else???…

love it … plus, orange is my favorite color!!!

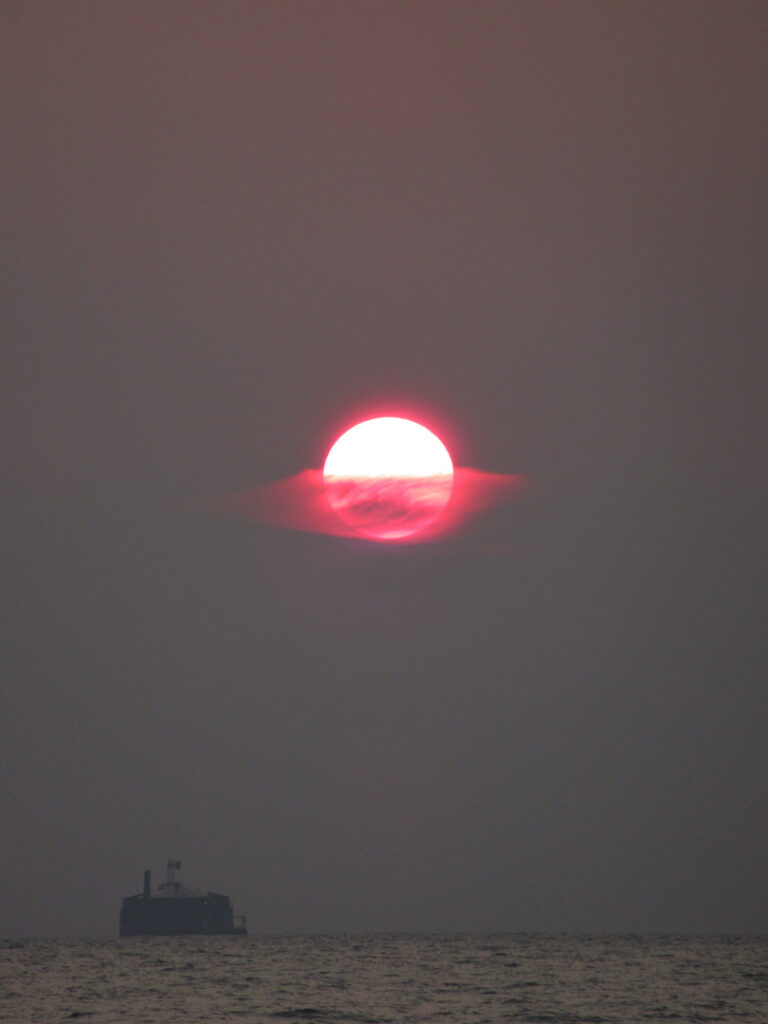

Sure, we finally got some beautiful sunrise reflections… but I’m getting a little tired of this Canadian wildfire haze still hanging around Chicago. The hazy horizon, the delayed sunrise & the glowing red sun. It was cool at first… but I’m ready for some clear skies & colorful clouds again! Just sayin’…

Celebrating NATIONAL CHOCOLATE CHIP COOKIE DAY

with a quick snack after teaching class.

And thinking of my Mom who used to bring homemade cookies

to almost every art fair!!! Such sweet memories…

Tonight in class, one of my students returned after two weeks traveling in Australia & Los Angeles. It was great to have Michael back… and luckily his pots were still leatherhard for trimming… and, oh but wait there’s more… he also brought some OREOs back from Australia for us!!! Thanks Michael!

Another red sun morning with the Canadian wildfire smoke still hanging around over the lake. Wispy clouds creating colorful reflections waiting to reveal a big “red ball” of a sunrise!

Spent today playing hooky with my cousin Kim. We had a lot of great adventures & laughs along the way. We ended up at her place… where I saw her peach tree FULL of peaches. Too many peaches? Is there such a thing?… yes! They were EVERYWHERE!!! I can’t even imagine stepping out my back door to find hundreds of peaches at arms length. Crazy!!!

And yes… of course she sent me home with a bunch of homegrown peaches!!! So yummy!!!

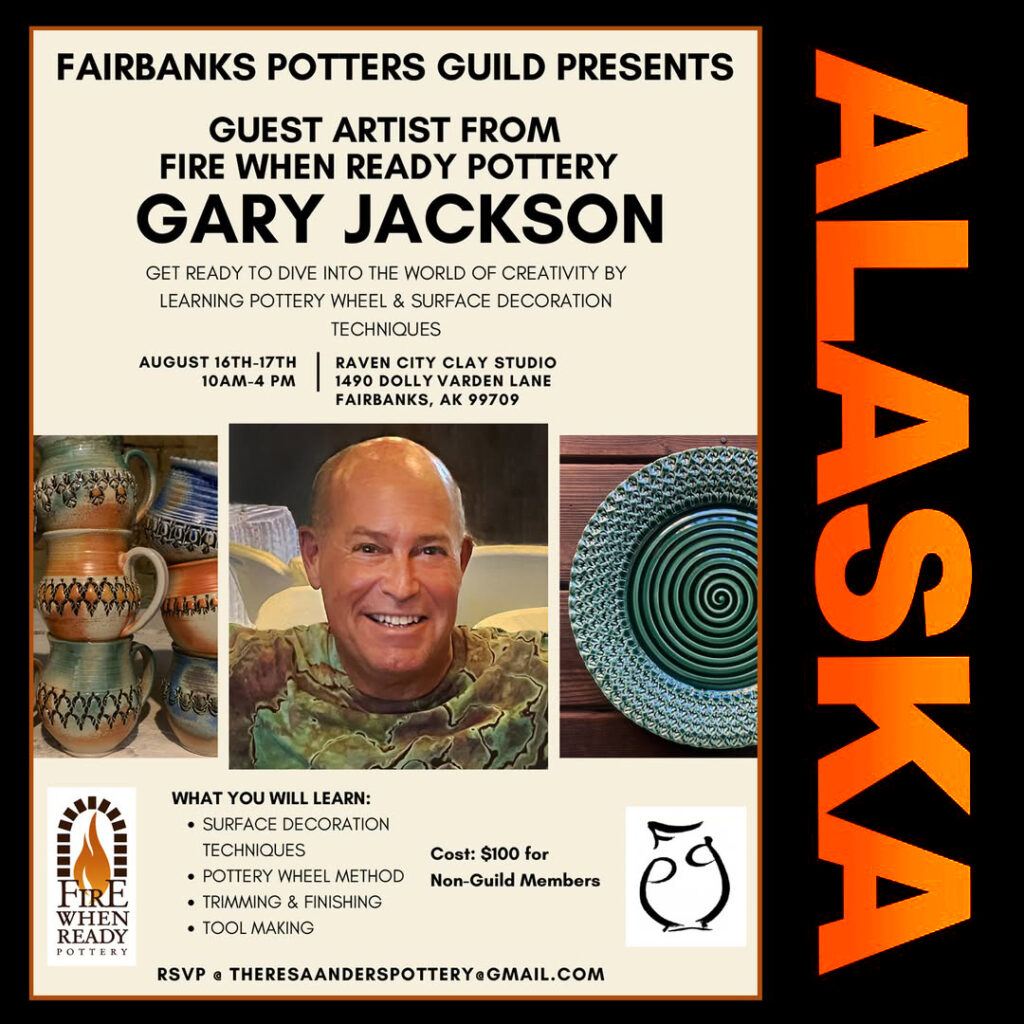

It’s hard to believe that in just two weeks I’ll be up north teaching a pottery workshop on ALASKA!!! Huge thanks to the Fairbanks Potters Guild for inviting me for this “bucket list” adventure!!! I can’t wait to finally see Alaska… I’ve heard such great things. Plus, I get to meet new potters & share my own pottery adventures with them for two days. Anyone else ready for an impromptu “adventure“ to Alaska to join in the fun? It’s not too late!!!

|

Gary Jackson: Fire When Ready Pottery

Lillstreet Studios ∙ 4401 North Ravenswood, Chicago, Illinois 60640 ∙ 773-307-8664 gary@firewhenreadypottery.com |