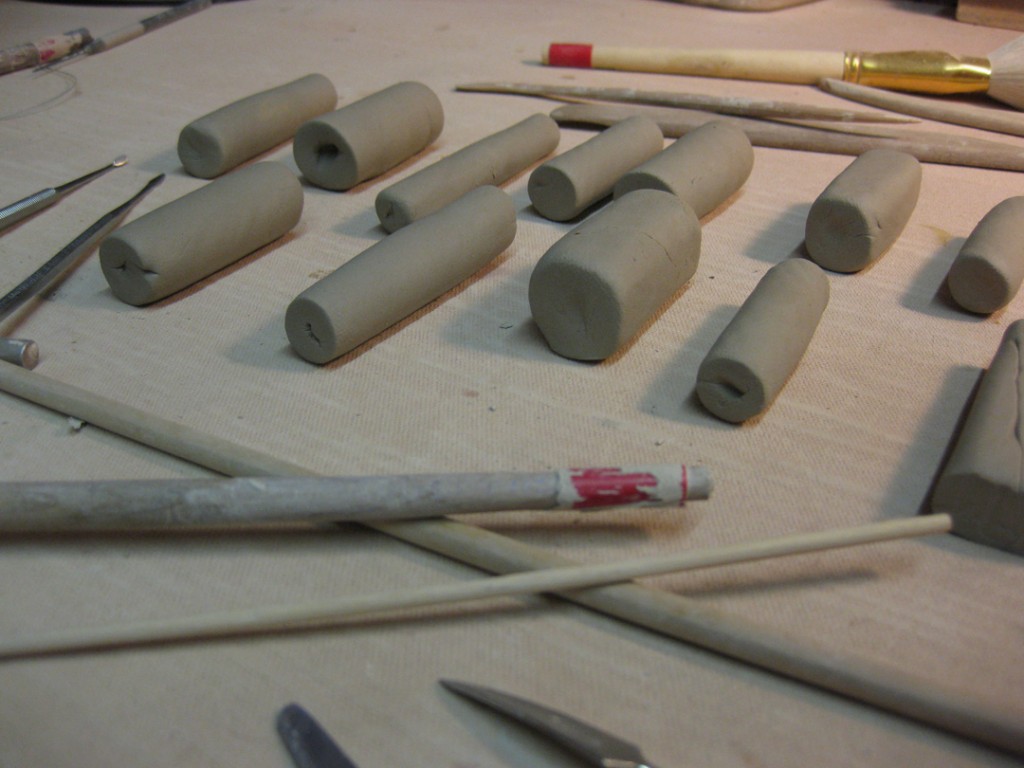

After a couple days under plastic, the enclosed forms were stiffened up a bit…

but just enough to trim, stamp and squish. I hadn’t planned on working on them tonight.

But I checked the after class and realized that they were at the right stage of dryness.

I was a little afraid to leave them another day for fear they might dry too much.

If they get too dry, they don’t squish so much as crack when flattened.

So I trimmed some of the edges, then stamped the rim – and squished!

And now, it’s late, I’m tired… and these will have to wait for another day under plastic.

Next up – some slip decoration and a hole pierced through the back for hanging.

Then they’ll be ready for drying, bisque firing, glazing & firing again.