So here’s the platter I threw for my class demo last Tuesday night.

I was hoping to keep it wet enough to stamp it as “class demo part two” next Tuesday.

But it was getting a little too dry a little too quickly. So I had to stamp it today. Here’s the

“demo” I was planning to share… this time in a sequential photo format.

The chosen stamp prepared to make its mark on the platter!

Just getting started… pressing the stamp into the moist clay one, by one, by one…

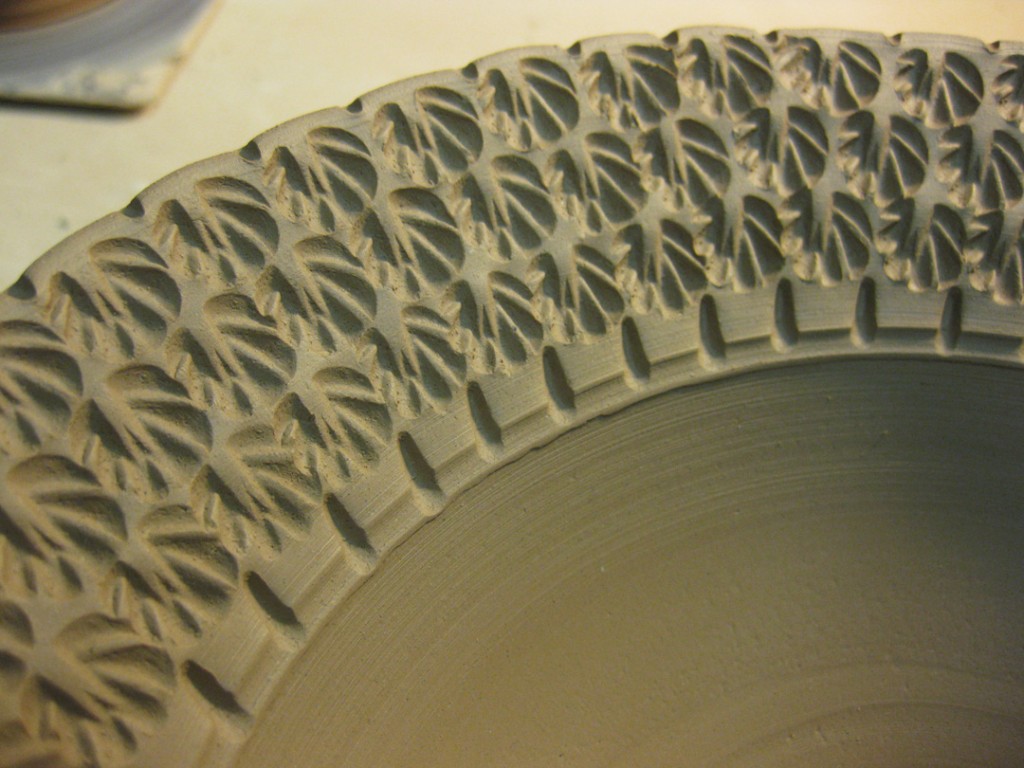

One row of stamping done. I always love to see how a basic platter can be transformed

so quickly with just a few impressions!

And if one row is pretty, a second row can only make it prettier, right?!

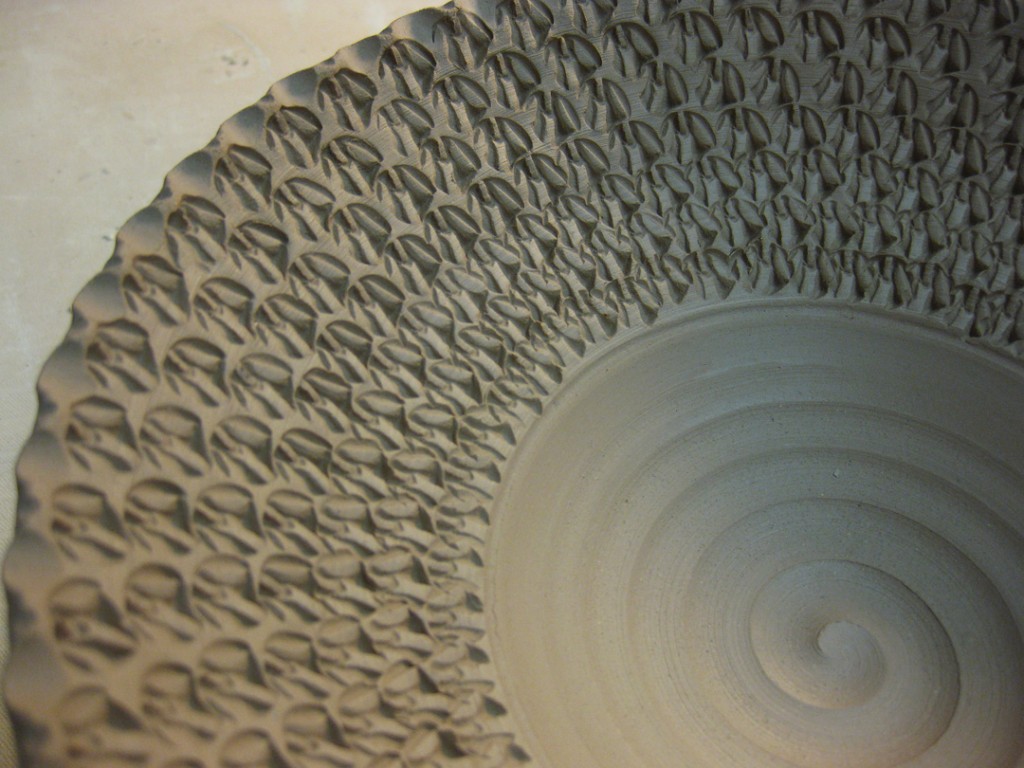

But why stop there? So I finished it off with some scalloped edge stamping. And some small

detailing with notches in the rim and small indentations in the stamps at the points.

Here are the three tools that did all the work… a stamp, a wooden tool… and my hand!