What better way to celebrate than with another batch of mugs freshly stamped, assembled & accents painted with colored flashing slips.

Gary Jackson: Fire When Ready Pottery

A Chicago potter’s somewhat slanted view of clay & play |

What better way to celebrate than with another batch of mugs freshly stamped, assembled & accents painted with colored flashing slips.

Stamped mugs getting a little lovin’ with some accents painted with colored flashing slip. If all goes well during the soda-firing, this slip will change to a smooth orange color with nice flashing effects.

Here we go again… more handles… more fun… making more MUGS!!! Always my favorite thing to make!!!

Just finished stamping, trimming & adding colored slip details to the lidded jars I started as part of a demo for my Intermediate Wheelthrowing class last week. Always feels good when everything fits together… and you set them aside to start drying!

I did a LOT of trimming today… mugs, vases, jars, etc. Could have been a tough day… but so much easier with some of my favorite studio tools! Loving my Giffin Grip & DiamondCore Tools … the perfect pairing to make trimming a joy!!!

Makes me LOVE TRIMMING even more!!!

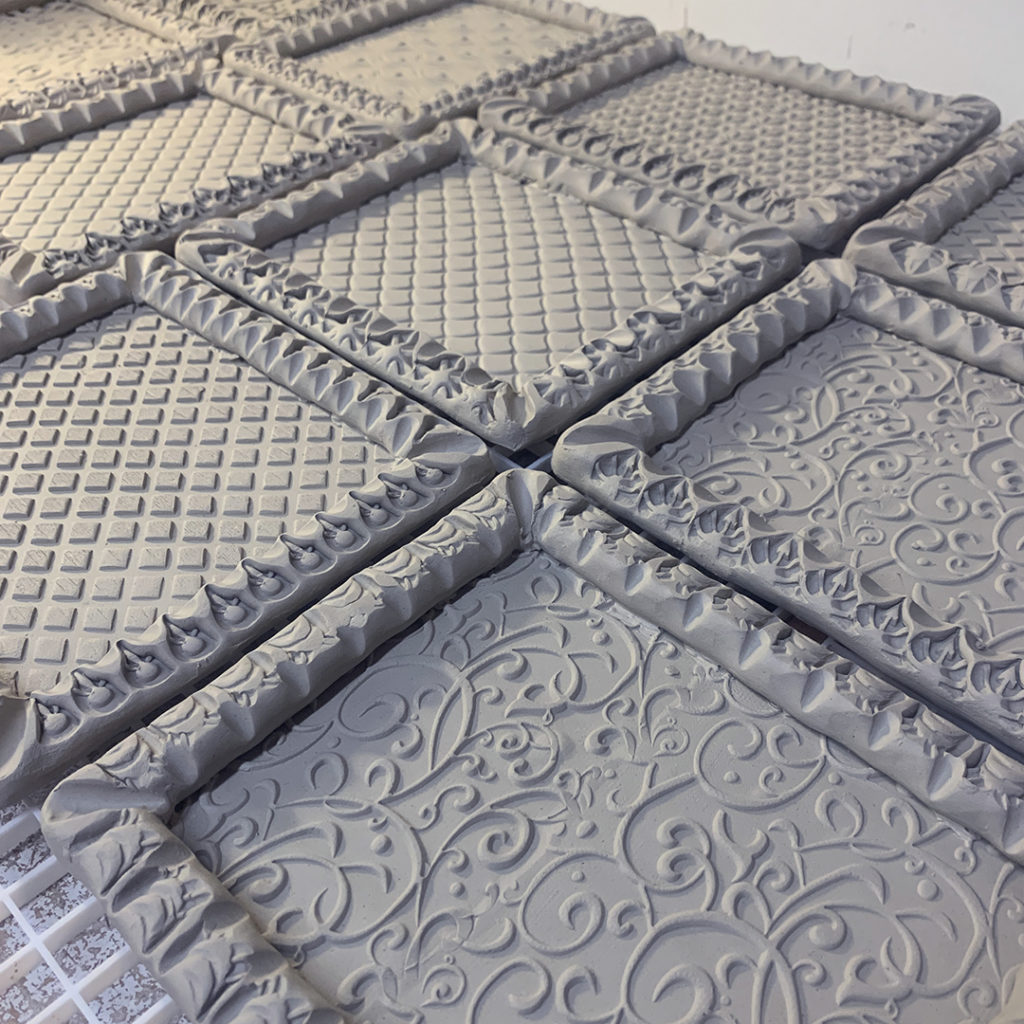

Well, it was bound to happen.. another batch of textured picture frames as part of another upcoming collaboration with painter Mary Foster. We first introduced these collaboration pieces at ART IN THE GARDEN this summer… and kinda figured we should do it again for THE COZY COTTAGE POP-UP in November. She’s already got a head-start on her paintings… so I felt as though I had better get my act together too!

Finishing off another batch of mugs to celebrate another MUGSHOT MONDAY!!! Stamped, handled & accented with colored slips for soda firing!!

Getting ready to add make some handles… and then make some mugs! Always my favorite thing to make!!!

After stamping, trimming & adding handles… I added some colored flashing slip accents to the latest batch of mugs! The band along the top with a smidge on the stamped impressions… and these slips will change colors during the soda firing!

After bisque firing my chain, I started adding some inlaid glazes into the stamped details. After soda-firing, the chain should be toasty & shiny with some stamped textures & patterns!

#2021chainchallenge – #handmadechain – #chainlinks2021

|

Gary Jackson: Fire When Ready Pottery

Lillstreet Studios ∙ 4401 North Ravenswood, Chicago, Illinois 60640 ∙ 773-307-8664 gary@firewhenreadypottery.com |