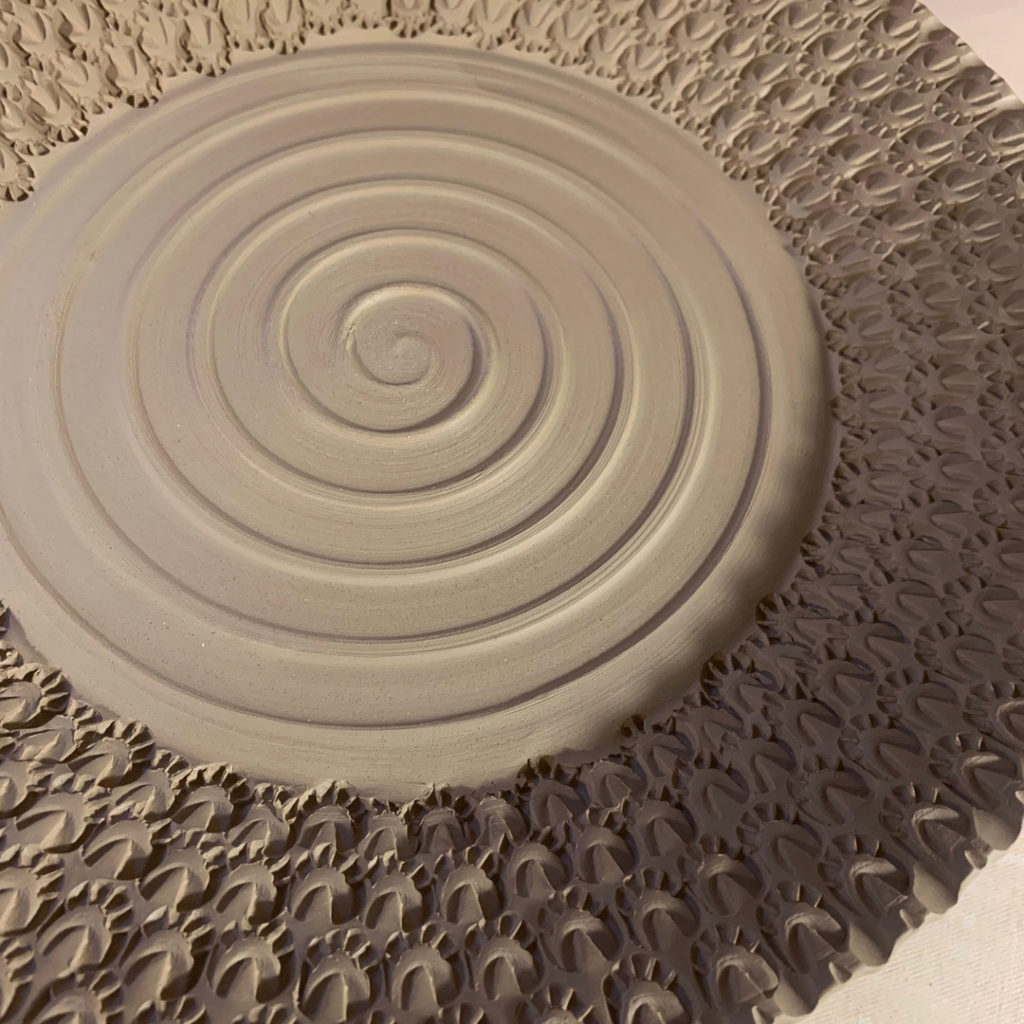

Just a handmade stamp & a pointy piece of wood. Soon enough I had this fully stamped platter ready to start drying more. Still needs to be trimmed… but one step closer to done!

Gary Jackson: Fire When Ready Pottery

A Chicago potter’s somewhat slanted view of clay & play |

Just a handmade stamp & a pointy piece of wood. Soon enough I had this fully stamped platter ready to start drying more. Still needs to be trimmed… but one step closer to done!

Fiddling around with a little clay tonight… making some leaves… and making some new “plans” hopefully for the “4×4 : Four Makers” Show. Starting small, making more… and trying to figure out where these leaves might end up?! Fingers crossed...

Making a few more stamped mugs on another Mugshot Monday!

Score, slip, attach, repeat… MUGS!!!

Another day of making mugs! Adding handles & adding colored flashing slip accents. A band of color around the top & a dab of colored slip on each stamp. If all goes well, this flashing slip with change to vibrant shades of gold in an upcoming soda firing!

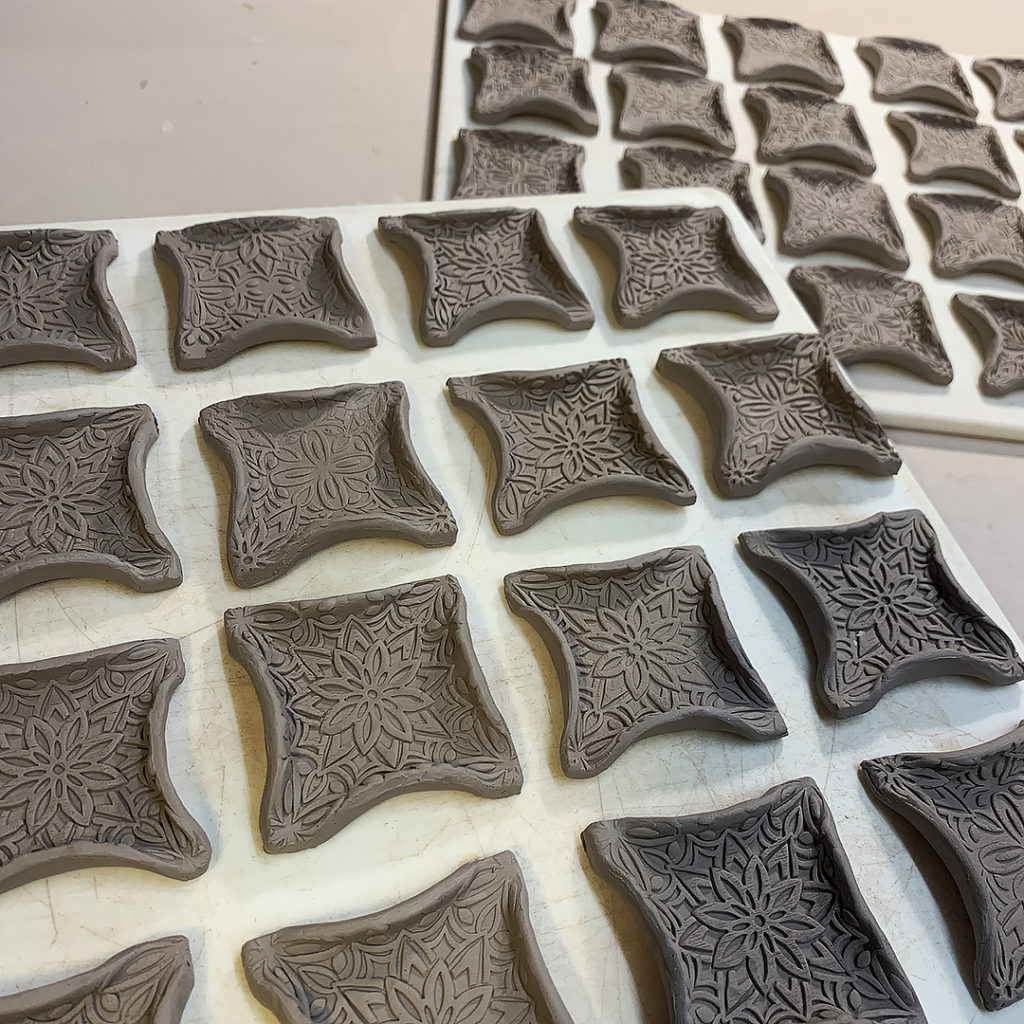

You know I’ve always said “MORE IS MORE”… well “more” of these little tiles are starting to come together! I’m kind of excited with this new “plan”… hoping they all come together for my “4×4 Sculpture Show” the first weekend in March with my talented friends Sarah Chapman, Darlys Ewoldt & Robin Kittleson! Mark your calendars!!!

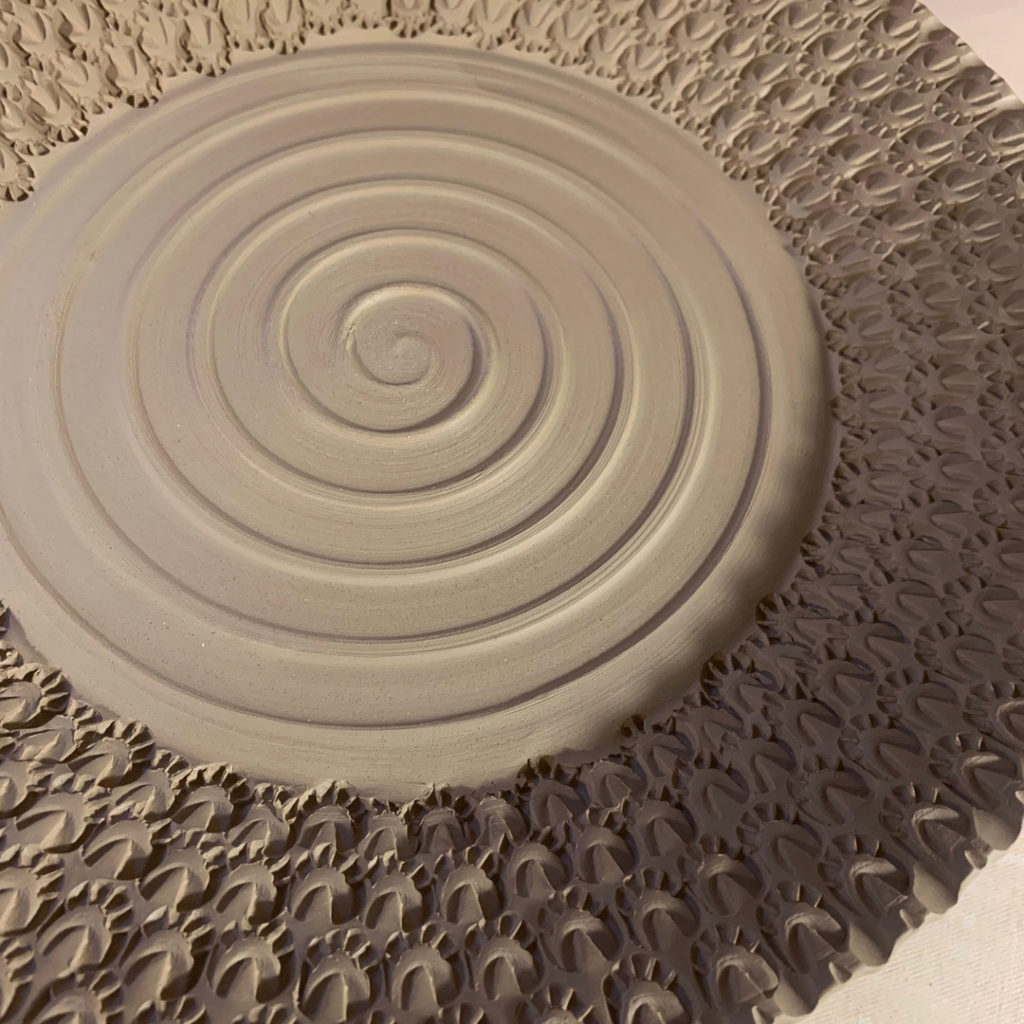

Just fidgeting & playing with some little textured squares. Not 100% sure of what I’m doing here… but I think I feel a little bit of a plan coming together. Hopefully in time for the “4×4 Sculpture Show” I’m doing the first weekend of March in Evanston. More details to come… if this plan actually comes together?!

Score, slip, attach, repeat… repeat… repeat. Mug handles all attached & ready to start drying slowly! Just in time to make it downstairs to teach class tonight! The perfect way to celebrate another Mugshot Monday!

Handles pulled & looped over so they can start setting-up. I like to loop them like this so they “dry” a bit with the curve already established before attaching them to the mugs. A little bit of finesse is needed while attaching them later… but most of the handle curve is already there!

Here we go again… another day of adding handles onto mugs! You know mugs are my FAVORITE thing to make… so here we go! Starting with these carrot-shaped nuggets of clay getting ready to pull handles the old-fashioned way!

Cleaning off the bottoms of these stamped cylinders and creating footrings at the same time. Always more enjoyable when I’m using my DiamondCore Trimming Tools for sharp, clean trimming ribbons… and my Giffin Grip to keep everything centered & secured!

|

Gary Jackson: Fire When Ready Pottery

Lillstreet Studios ∙ 4401 North Ravenswood, Chicago, Illinois 60640 ∙ 773-307-8664 gary@firewhenreadypottery.com |